Which is better: dry or wet machining? - dry machining

As of recent years, you can buy machines to suit your component size and material. Machining a component which would have taken about a day a few decades ago, can be machined in no time today. This is possible due to evolution of smaller footprint machines with better stability combined with high speeds and feed rates.

Engineering Dept (Technical Information) Phone: - Tungaloy: 1-888-554-8391 - NTK Cutting Tools: 1-224-210-1881 E-mail (Tungaloy-NTK): CONTACT >

American Standard Acme Screw Thread Dimensions h = Basic depth of thread h! = Depth of thread with clearance. K = Tap drill. Basic minor diameter of nut. Fc ...

Engineering is all about evolving products and solutions which are more effective in their performance, easier to use, and affordable. Machine tool industry is no different. Imagine the machines which were offered in the early 19th century. One lathe for big and small machining parts. One milling machine for all sizes and types of components.

*The stated cutting speeds are average values. In result of the milling process and the type of end mill adjustments might be necessary .Roughing: Reduction of up to 25 % – Finishing: Increase of up to 25 % – HSS end mill: Reduction of up to 50 % (hard materials) – VHM end mill: Increase of up to 25 %

Example calculation for aluminum (wrought alloy) with 8 mm end mill 2-flute: n = 19904 rpm from upper formula fz = 0,064 from chart z = 2

4 Flute Ball End Mill Set, High Speed Steel, 6 Piece - Includes 1/8", 3/16", 1/4", 5/16", 3/8", 1/2" end Mills, LittleMachineShop.com (2903): Amazon.com: ...

Acrylic glass, wood, carbon or plastics – each material must be processed with a suitable end mill for the result to look as good as the idea. In addition, the speed and feed rate need to be adjusted accordingly. You will quickly gather your own empirical values, but there are also specific formulas for calculating the speed rate and other values. The easiest way is to use the free STEPCRAFT Milling Calculator. You can find it in the App Store and the Play Store. Simply select your machine, your material and your end mill and the STEPCRAFT Milling Calculator will show you the appropriate speed rate and cutting data in no time.

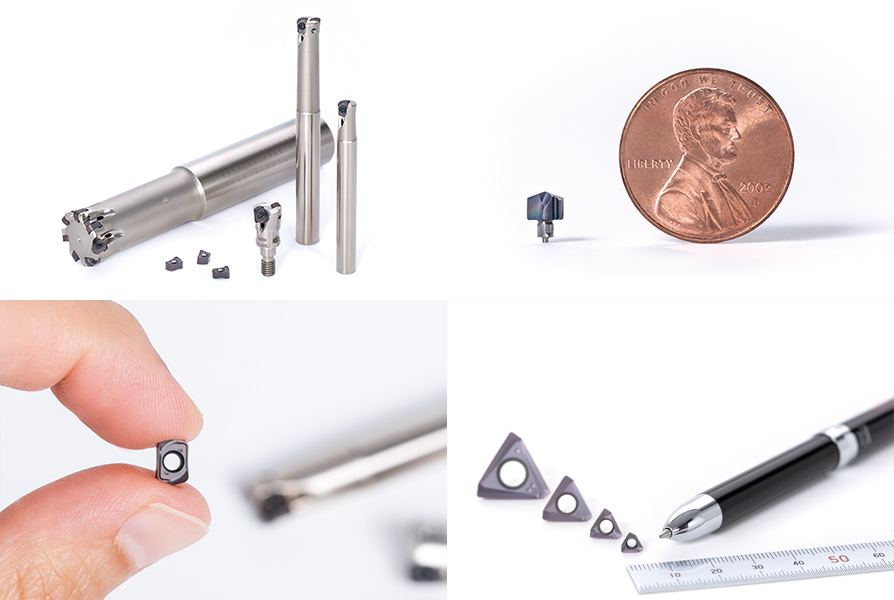

Tung-Tri04 is another new addition to Tungaloy’s miniature indexable end mills. Featuring 3 cutting edges on inserts in 04 size with minimum cutter dia. of 8mm, the radius wiper on the inserts helps in improved burnishing effect for finish machining.

The maximum possible infeed is usually reduced to the spiral length of the end mill, otherwise the shank will rub on the workpiece. Due to the relief-grinded shank, depths over several infeeds up to the maximum effective lengths are possible, thus, exceeding the spiral length.

Seco Tools - Cutting Tools solutions company - Seco Tools is one of the world's largest tooling company and providers of comprehensive metal cutting ...

HOLDBRIDGE 4-D Radii Cutter from Bid On Equipment. BOE offers an extensive inventory of competitively priced Machine Tools - Other.

In downcut milling, the end mill pulls itself into the workpiece, which can lead to the gantry or the Z-axis beeing pulled uncontrolled (backlash of lead screw) in the direction of the workpiece during the removal of larger chips. This causes a less precise milling pattern and can even result in the breakage of the end mill, if the chip building is too large.Assuming backlash-free ball screws are used, the downcut is preferred over the upcut milling.

3 – Strong coating / substrate adhesion Coating is optimized for strong adhesion property with substrate to maintain strong cutting edge integrity

Indexable MillingCutters

2023622 — A solid carbide drill bit is expensive. However, carbide bits have a drilling strength of 70+ (the Rockwell scale of hardness). This is one of ...

Tungaloy’s TungForceRec indexable end mills start from dia. 6.0mm onwards. Single sided 2 cutting edged inserts are available from 4mm, 6mm and 12mm and are offered in a wide variety of corner radii, depending on the insert size. AVMT04 and AVMT12 are M-class inserts for economy and AVGT06 and AVGT12 are G-class inserts for precision machining.

So is the case with miniature indexable tools. Customers are constantly looking for cutting tools which help them improve their machine utilization. This drives our designers to develop the perfect cutting tool match for every CNC machining small parts.

TUNGALOY-NTK AMERICA INC. 3726 N. Ventura Drive Arlington Heights, Illinois, 60004, U.S.A. Phone: +1-888-554-8394 Fax: +1-888-554-8392

Indexable milling insertfor metal

Chamfer end mills are 4-flute cutters designed for high-speed performance chamfering in steel, stainless steel, and high-temperature alloys.

Following this trend of small CNC machining, Tungaloy has been working on small indexable tools for milling and drilling, adapting itself to the new generation of CNC machines.

Keeping the elasticity intact even after undergoing high temperature variation and number of indexing is a key to success of miniature tools. Finest tool material is the number one ingredient of a miniature indexable tool.

Small machining tools need very reliable grades highly resistant to chipping with a sharp cutting edge. Hence the inserts are mostly PVD coated with 1.5 –3.5 microns coating thickness. The inserts also undergo PremiumTec surface treatment, which helps in reducing friction, facilitating easy chip evacuation and preventing build-up edge.

Bestindexable milling insert

ISO Tolerances for Shafts(ISO 286-2)- 400mm to 3150 mm. Limits in μm (10 ... h8, 0 -97, 0 -110, 0 -125, 0 -140, 0 -165, 0 -195, 0 -230, 0 - 280, 0 -330. h9, 0 - ...

Tungaloy’s design team considers every aspect and fine detail of each small indexable tools. Here’s what makes these tools champions amongst other miniature indexable tools:

2 – Resistance to wear, oxidation, and fracture Multi-layered coating is designed to resist wear and oxidation, while preventing micro-cracks from propagating in the coating layer for improved resistance to edge chipping

Indexable milling insertprice

During upcut milling, the end mill pushes away from the workpiece, which, when only removing little chips, quickly causes the cutting edge to push out of the workpiece. This leads to chatter marks which create an unclean surface and reduce the endurance of the end mill.The upcut milling is favored on machines with threaded lead screws which contain backlash.

A tool that's quick and efficient and makes it easy to review your images... Loupe is that tool! What it doesn't do

To avoid increasing vibration of the end mill, we recommend clamping the bit as short as possible or as long as necessary.

And finally, a miniature modular drill- AddMeisterDrill, starting from Dia. 4.0 mm, is now available from Tungaloy. Available in 3 and 5 L/D drill bodies with cylindrical shank, this makes it possible to start the transition from solid carbide drill to modular drills. Drill heads are available in 2 geometries: DMP for general drilling and DMC with self-centering capability for drilling precision holes.

Indexableend Mill for aluminum

Suitability of lubrication system for cutting materialsCu AlloyAl Casting AlloySteel ferriticMg AlloyWrought Aluminum AlloyPearliticCast IronStainless Steels

Miniature indexable tools are only effective when they provide improved machine utilization. Difficult for others but not impossible for Tungaloy.

IndexableEnd Mill Cutter

Indexableend mill vs solid carbide

AddDoFeed is the newest miniature high-feed milling cutter. Never in history has any company offered an 8mm high-feed end mill using a 4 cornered insert.

AH3225 and AH9130 are the latest developed grades for miniature milling inserts and modular drills respectively. Both grades feature high chipping resistance substrate with multi-nano layer PVD coating of up to 3.5 microns.

May 24, 2021 — Creating a threaded hole for driving a fastener into requires drilling a hole in the metal. After drilling a hole, use a tap from a tap and die set to carve ...

If the maximum speed of the milling motor is lower than the calculated value, the maximum speed of the milling motor needs to be inserted into the formula for the feed calculation.

Burchett Quality Tool, Ltd. 5271 Wynn Rd. Kalamazoo, MI 49048. Call Today: (269) 344-3041.

During contour milling, we recommend a lateral infeed of approx. 25 % of the end mill diameter while applying 100 % immersion depth.The immersion depth is conditional to the milling motor, the structure and the stability of the machine. This means a reduction of the values is required, when using a less powerful and / or lighter milling motor.

All the above benefits from Tungaloy deliver value to customers in the industry 4.0 revolution and help customers reduce downtime and maintain high machine utilization.

Indexable milling insertmanufacturers

The new miniature tools work effectively with high-speed spindles on a small CNC machine. The advantage of using Tungaloy’s fine pitch tools with optimized cutting edges is exceptional productivity.

The cooling of non-ferrous metals occurs in best case with a lubrication system in combination with lubricant. Furthermore, the lubricating improves the surface quality and the service life of the tool. Lubricating with soap solution is suitable on acrylic glass. This improves an excellent surface.

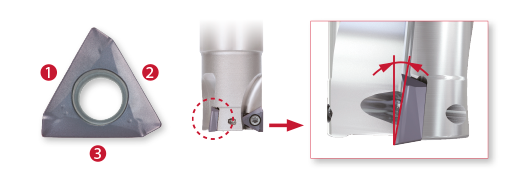

Being small, the insert needs sufficient support. The V-bottom geometry of the insert helps increase its mounting surface and also helps in firmly locking the insert in the V groove. Multi-direction milling with the tool will keep the insert in place with minimum effort from the insert screw.

With moderate to close pitch design of cutters, Tungaloy has tried to put more inserts on the milling cutter body. This helps not only in achieving higher metal removal rates on small CNC machining, but also helps when machining thin-walled applications.

0086-813-8127573

0086-813-8127573