Why 3D printers can't be CNC mills - 3d printer cnc conversion

PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) coatings possess advanced coating architectures which provide a multiplicity of surface characteristics not attainable with standard coating treatments. Special sputtering techniques, low-pressure plasma treatments and specialized equipment enable full coverage of complex, intricate tooling geometries and create a variety of unique material properties.

Center drill vs spot drillreddit

Peptide helical wheel projections are drawn in such way that the observer sees the helical structure from the same axis which the helix grows. This is done by ...

At Endura Coatings, we offer the Series 600 PVD / CVD coatings. As part of our pricess we have 4 steps for these coatings.

Center drill vs spot drillsize

Specific coatings are FDA compliant, USDA approved and biocompatible with ISO 10993 and commonly used in industries such as food packaging and food processing.

Twistdrill

The 27880/27820 Timken is a single-row tapered roller bearing. This bearing type gets its name from the tapered rollers between the inner and outer rings. The ...

Step 3: Different materials can be deposited in different forms (polycrystalline, amorphous, monocrystalline etc.) to meet certain functional objectives. Such materials include, but are limited too:

Center drillSizes

Step 3: Metal vapors aredeposited on your substrate via an evaporation and ionization process. Single or multi-layer coatings may be applied in one processing cycle. Such materials may include, but are not limited to:

Order food delivery and take out online from Harvey's (329 Caradoc St S). Browse their menu and store hours.

Product name:Carbide steel turning blade;Application:CNC Lathe Machine;Type:Cnc Tool Parts;MOQ:1 PCS;Model:WNMG080404-MT;Package:10pcs/plastic Box ...

Spot drillangle

Please complete our Coating Requirement Questionnaire or call us at 1.800.336.3872 to review & discuss your project requirements. Submit Requirements Online

Spot drillsizes

Center drill vs spot drillfor steel

Harvey has received eight Graham and Dodd Awards/Scrolls for excellence in financial writing from the CFA Institute. He has published over 150 scholarly ...

Dec 3, 2019 — Would like to pull names from a database to insert into a video message to personalize it for each person, delivered via link in email.

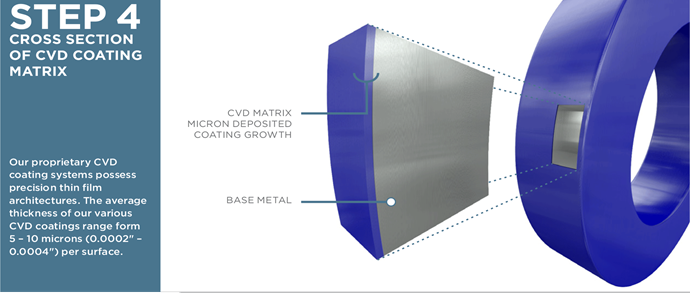

Step 4: Our proprietary CVD coating systems possess precision thin film architectures. The average thickness of our various CVD coatings range from 4-12 microns (0.0002" - 0.0005") per surface.

HSS (High-Speed Steel) and Super Speed Steel cutters are top tools due to their strength and versatility.

Spot drillbit

Full-service CNC tool grinding, centerless and cylindrical grinding. New tool sales, design and manufacturing.

1 Postal Code in Zhuji, Zhejiang ; 311800, Zhuji, Zhejiang ...

Primary surface enhancements of pvd coatings and cvd coatings include extraordinary resistance to wear and hardness, and may also include non-wetting, dry lubrication, low friction, corrosion protection, heat transfer, or resistance to thermal oxidation.

CONVENTIAL MILLING SHOULD BE USED AND FEED PER TOOTH SHOULD BE REDUCED BY 50% ... FORMULA FOR COMPUTING TABLE SPEED IS. .001 X NUMBER OF TEETH IN CUTTER X RPM.

Step 4: Our proprietary PVD coating systems possess precision thin film architectures. The average thickness of our various PVD coatings range from 2-5 microns (0.00008" - 0.0002") per surface.

0086-813-8127573

0086-813-8127573