Why so cross? - cross drill

Titanium nitridecoatingat home

A Brooks Instrument Quantim® Coriolis mass flow controller is used for control of the liquid feed of TiCl4 to a vaporizer, such as the DLI vaporizer, developed by Brooks Instrument and available through Ceres Technologies under a license agreement. This vaporizer system uses a gentle vaporization technique to ensure high integrity of the TiCl4 supply to the furnace. The liquid feed to the vaporizer is combined with a carrier gas, such as N2, reducing the required heat to vaporize the TiCl4. This eliminates decomposition of the TiCl4 due to excess heat, providing a consistent vapor into the furnace.

Plastics come next in terms of popularity for milling. They also have desirable properties and are widely used. Polymers like ABS, PEEK, polycarbonate, and nylon are some of the plastics that regularly undergo CNC milling.

Used for workpiece circular aperture chamfering or cone hole, the edges on the surface of the chamfering processing. 4 x Chamfers Drill Bit.

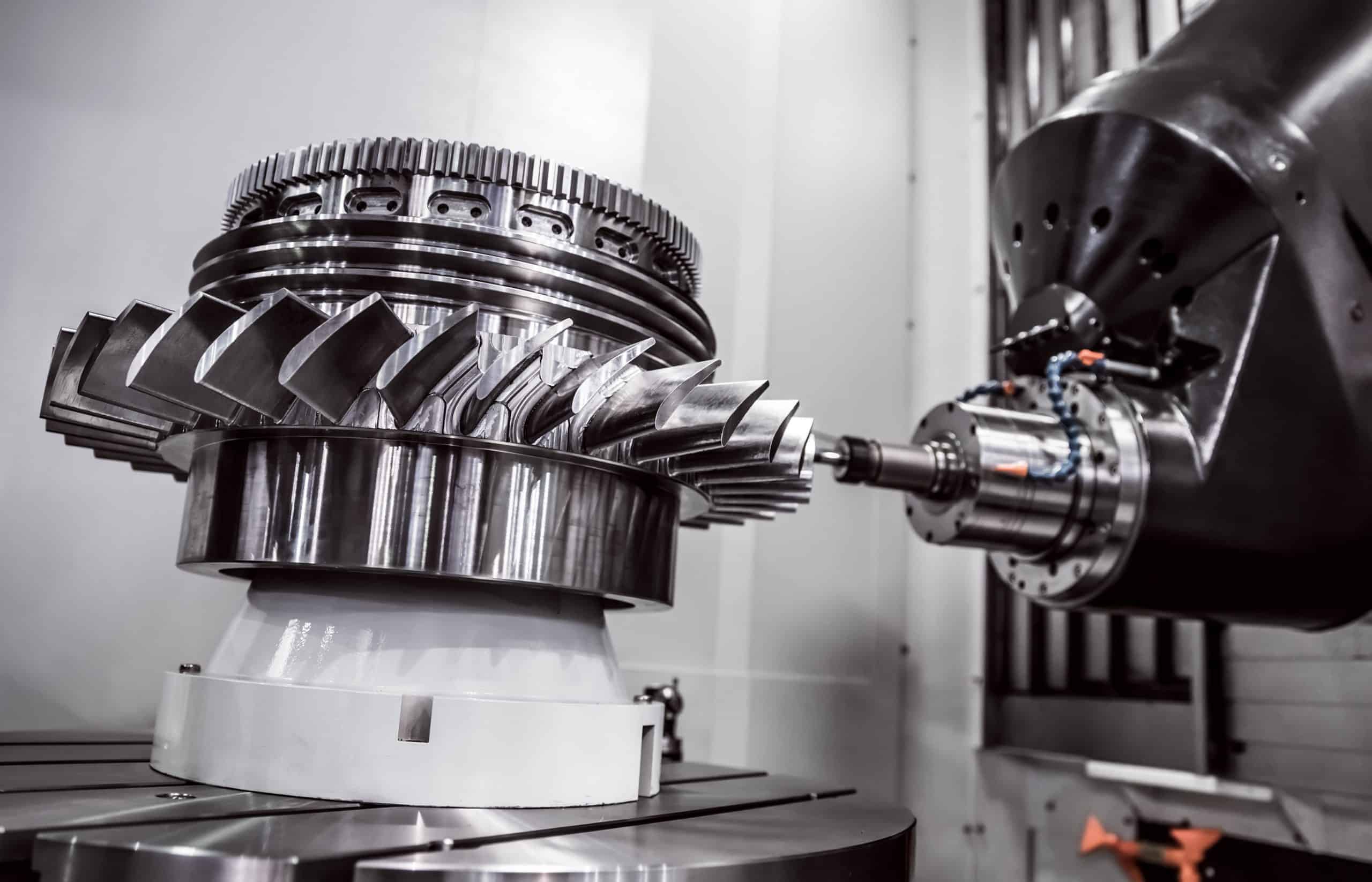

5-axis CNC mills can further be classified as indexed and continuous. In indexed 5-axis mill, the cutting tool has to momentarily stop moving as the workpiece rotates. In continuous 5-axis mills however, there’s no need for the cutting tool to stop. The workpiece rotates simultaneously as the cutting tool moves.

Metals and metal alloys are the most frequently milled materials. This is because of their vast use across several industries. Commonly milled metals are aluminium and its alloys, the various types of steel, brass, copper, titanium, and bronze.

Because milling is typically a high-speed process, it usually generates a lot of heat as a result of friction between the workpiece and the cutting tool. This makes it necessary to cool them down using substances known as cutting fluids.

CNC milling can produce parts with very high dimensional accuracy. Tolerances as tight as 0.025 mm are feasible. This high accuracy is crucial to aerospace as well as automotive industries.

Ti coatingreviews

UTC+8 (China Standard). Postal code. 361006. Area code, 0592. Website, www.huli.gov.cn. Contents. 1 Geography; 2 Administrative divisions. 2.1 Subdistricts. 3 ...

Looking for DAP® 74327 CDA HVAC SILICONE CLEAR clear 298ml? Get it at Reno Liquidators, Top Rated Online Caulk & Sealants Store in Canada.

View a summary page of this 2010 CONTRACT to INDUSTRIAL TOOL PRODUCTS INC from the Department of Defense.

If your application is sensitive to moisture or requires high purity, Brooks Instrument also has a variety of solutions available to suit these needs.

CNC milling machines can be classified according to the orientation of the spindle as vertical and horizontal mills. Before selecting between these two types of mills for a milling project, an operator must consider the demands of the project such as the shape and size of the part, and the number of surfaces to be milled. For example, while vertical mills provide more versatile machining options, horizontal mills are better for heavy and long workpieces.

Depth of cut is the distance the cutting tool moves into the surface of the workpiece. The material also determines this parameter.

Thread angle is a common characterization of lead screws, with acme screws having a thread angle of 29 degrees and trapezoidal screws having a 30 degree thread ...

Titanium Nitridecoatingnear me

One of the following continues intermittently, making small cuts at a time until the machine produces the desired object. As the tool comes in contact with the workpiece, its cutting edges repeatedly dig into and exit the surface of the workpiece, effectively shaving off chips from the workpiece through shear force.

HOLIDAY HOURS: Our U.S. facilities will be closed on Thursday, November 28 and Friday, November 29 in observance of the Thanksgiving holiday. Normal business hours will resume on December 2nd.

The cutting tool or workpiece in 3-axis CNC milling machines has three degrees of freedom. This means they can move in three linear directions; X-axis (left and right), Y-axis (back and forth) and Z-axis (up and down). In order to enable the cutting tool to reach certain areas of the workpiece, the workpiece has to be manually repositioned.

With high accuracy, repeatability and superior long-term zero stability, SLA Series MFCs provide a highly reliable, leak free component critical to the CVD system, yielding excellent results at initial startup through the entire life of the CVD process. The SLA Series has many options available to tailor the MFC to the specific application, from different process connections to Hazardous Area ratings on SLAMf Series mass flow controllers & meters.

In angular milling, the axes of rotation of the cutting tools are at an angle to the surface of the workpiece. They are known as single-angle milling cutters. Angular milling produces features like dovetails, chamfers, grooves, etc.

There are over 50 engineering materials that can undergo CNC milling, as long as you use the correct cutting tool and cutting speed. Whether your material is metal, plastic, wood, glass, or even rock; if you have an application for it, it most likely can be CNC milled. Also, CNC milling has very little to no effect on material properties.

After setting up the machine, the operator initiates the milling process through the machine interface. The machine begins the actual milling by rotating the cutting tool around its axis at a very high speed of up to thousands of RPM (revolutions per minute). Depending on the nature of the milling machine, cutting action on the workpiece is achieved by one of the following movements:

Titanium Nitridecoatingthickness

In subtractive manufacturing processes such as CNC milling, cost increases as the amount of material the machine needs to remove increases. Therefore, the cost of milling complex geometries which require a lot of material removal increases with the level of complexity.

This is the distance the workpiece or cutting tool moves, per revolution of the tool. Like speed, you can also program feed. Feed also depends on the material you want to mill.

CNC milling is one of the most widely used machining processes. This article explains the process of CNC milling, its advantages, limitations, and everything you need to know when you order CNC milled parts.

There are numerous milling operations which CNC mills can carry out, depending on the type of cutting tool and the machine configuration. The four primary CNC milling operations are:

The CVD process is commonly used to create titanium nitride coatings. In this process, several chemicals (TiCl4, N2 and H2) are fed into a furnace where they react at an elevated temperature to create TiN, which deposits on the surfaces as a coating. Critical to the integrity, proper thickness and uniformity of the coating is ensuring the accurate delivery of these materials into a furnace.

Before the incorporation of CNC, control in milling machines was carried out manually. This gave a lot of room for error. The end product was in the mind or view of the machinist, similar to the way an artist paints a picture. With the inclusion of CNC however, milling became a highly precise and accurate process, involving some steps. There are four sequential steps involved in creating a CNC-milled part:

Certain terms used in CNC milling may mean other things in other contexts. An understanding of these terms would help you understand your CNC machinist or designer better.

Brooks Instrument SLA5800 Series mass flow controllers & meters (MFCs) provide an excellent solution for accurate, repeatable delivery of the gas components. Several different signal options are available: analog (0-5 VDC or 4-20 mA) or numerous digital protocols, including Ethernet/IP and PROFINET. This allows for a versatile interface to the control system.

CNC milling machines do not understand CAD files in their native format. Instead, they depend on digital instructions known as G-Code which instructs them on how to move in 3D space. It is, therefore, necessary to convert CAD models into G-Code. This is where computer-aided manufacturing (CAM) programs come in. After completing a CAD model, the designer exports it to a CAD program which reads it and converts it to the corresponding G-Code.

Titanium nitridecoatingmachine

In face milling, the cutting tool’s axis of rotation is perpendicular to the workpiece surface. This operation creates flat surfaces and requires end milling cutters which have cutting edges at their tip.

TiNcoatingspray

CNC milling is a subtractive manufacturing process in which computer-controlled cutting tools progressively remove material from a workpiece in order to create a desired shape or object. This process is achieved using machines known as CNC milling machines or CNC mills. It is the most widely used of the mechanical machining processes, others being CNC turning and CNC drilling.

Next is the machine setup. Before running the CNC programme, the operator needs to set up the CNC milling machine by attaching the workpiece to the mill’s work surface; affixing the appropriate cutting tool to the mill’s spindle; and preparing any necessary cutting fluid.

Care must be taken to minimize contamination that can affect the integrity of the coating. Leaks or o-ring permeation in the system can lead to contamination from the room air. Improper vaporization of TiCl4 can lead to contaminated gas mixtures being delivered to the furnace.

Nov 21, 2020 — Can't seem to find feed/speed info for most inserts on the manufacturers website aside from Sandvik but not always.

Titanium is frequently used in these applications to create an extremely hard Titanium Nitride (TiN) coating on the target product. Due to its golden appearance TiN coatings are often used on jewelry, household fixtures and automotive trim for decorative purposes. Similar coatings are also used as a non-toxic surface for medical devices and equipment. These types of coatings are now also being applied in advanced biomedical device applications including in-vivo biosensors.

Designed to mill a radius on the backside of a workpiece. Ground from solid carbide, tools within this offering feature 5° flares at the neck and shoulder to ...

Reference genome for the Human Microbiome Project Organism: Phocaeicola dorei DSM 17855 (Taxonomy ID 483217) BioProject Accession: PRJNA27831 ID: 27831.

Ti coatingpvdcoating

Milling is a very versatile process that applies to numerous materials. When selecting a material for CNC milling, there are many factors that you should consider like cost and material properties. Material properties include tensile strength, thermal resistance, hardness, chemical resistance, and shear strength.

Form milling involves the production of irregular surfaces, contours, semi-circular cavities, beads, and curved surfaces. This operation employs cutting tools such as fly cutters and formed milling cutters.

CNC milling applies to a wide range of production quantities, whether it is a one-off custom project or a small to large-scale production run. Together with its repeatability and speed, CNC milling’s scalability makes it excellent for either prototyping or mass production. CNC milling is excellent for large-scale production of identical units, as production costs exponentially reduce with an increase in the number of units.

To better understand the process of CNC milling, it is necessary to know the parts of a CNC mill. Parts of different milling machines differ by manufacturer, type, and capacity. However, there are parts that are fundamental to every CNC milling machine:

The inclusion of CAD and CAM program in CNC milling has greatly reduced the time taken from making an order to receiving accurately machined parts. Precision is maintained despite high speed.

While CNC milling is very versatile and ubiquitous, it may not be suitable for every manufacturing application. Other machining methods may prove more cost-effective and appropriate for your project. Some of these methods are as follows:

The cutting tool is a detachable component of CNC mills that carry out cutting action. Cutting tools for CNC milling usually have multiple cutting points. This is because, in milling processes, the tool moves perpendicular to its axis of rotation. There are various types of cutting tools that vary by material, form, number of flutes, and placement of cutting edges. The tool selected for a milling process is dependent on the material to be milled.

The first step in the CNC milling process is designing a CAD model of the part to be milled. This is carried out using CAD programs available for the purpose. Any feature that is to be a part of the final product must be indicated in the design. There are some standards and guidelines every designer should follow to properly design for CNC milling, which we have compiled.

TiCl4 will be in a liquid form, and must be vaporized to properly react with the other gases to ensure consistent results.

Likewise, the material you select determines many aspects of the milling process including the design of the part, the cutting tool, the cutting speed and feed, the cutting fluid, and the depth of cut. There are some materials that are popular for CNC milling:

Many industries depend on CNC milling for the production of parts. Likewise, individuals regularly need this process for their parts. In addition to its high speed and precision, the scalability and versatility of CNC milling make it almost indispensable to the following industries.

The Industrial Revolution in the 18th century marked the beginning of the alliance between man and machine, with the aim of manufacturing. Before this period, the main method of manufacturing was casting. This, alongside other methods available at the time, was manual, tedious, and error-prone. Today, however, with advancements in digital technology, manufacturing processes that can produce very complex parts with high speed and accuracy now exist. One of these is CNC (Computer Numerical Control) milling.

Speed in CNC milling refers to the speed at which the cutting tool rotates. It is measured in revolutions per minute (RPM). Speed can be programmed and it depends on the material to be milled. For example, you can mill aluminium at much higher speeds than Steel.

In addition to the three linear axes attainable in its 3-axis counterpart, 5-axis CNC mills have two rotary axes. In most milling machine configurations, the cutting tool can only move along three linear axes. The workpiece carries out the remaining two rotary movements, thereby giving the cutting tool access to another area.

Securing the workpiece in place is crucial in CNC milling processes. However, this creates some restrictions as the tool cannot access the portions of the workpiece being held. In such cases, the workpiece needs to be manually repositioned. This increases machining time and also increases the possibility of errors.

You'll be able to cut the silicone out with no issues if you're careful and just be sure to seal the hole when you repair/replace.

Titanium nitridecoatingprocess

When compared with formative and additive manufacturing processes, CNC milling creates a lot of waste material as chips. If you can’t recycle these, they may have serious environmental and cost implications.

There certain features such as curved holes, straight internal edges, and walls thinner than 0.5 mm, that cannot be milled. While we encourage you to avoid such features when designing for CNC milling, they are sometimes necessary for a part to function. In such cases, other forms of milling may be employed.

In addition to being able to produce various shapes, CNC milling can accurately machine a variety of features including, pockets, threads, chamfers, slots, cavities, etc.

Another major classification of CNC milling machines is according to the number of axis and axis configuration. In CNC milling, axis refers to the direction of movement of a workpiece or cutting tool. In our network, we carry out multi-axis milling operations including 3-axis, 4-axis, and 5-axis milling. These allow us to quickly and accurately produce parts from your designs ranging from simple shapes to complex geometries. 3-axis and 5-axis CNC mills are the most popular types of CNC milling machines.

The cutting tool for plain milling has cutting edges along its entire cutting circumference. Its axis of rotation is parallel to the workpiece surface. Plain milling produces features like pockets, slots, and cavities.

Feb 14, 2024 — The two different router bit materials are carbide-tipped and high-speed steel (HSS). Carbide-tipped bits, known for their durability and sharpness, are ...

0086-813-8127573

0086-813-8127573