Why You Should Choose Coarse Thread Bolts Over Fine ... - difference between fine thread and coarse thread

– You’re cutting really gummy cast aluminum plate. Definitely go to 2 flutes instead of 3, but you may find you have to go all the way down to a single flute.

Years ago, students were warned not to end a sentence with a preposition; time, of course, has softened that rigid decree. Not only is the preposition acceptable at the end, sometimes it is more effective in that spot than anywhere else.

On my visit with Datron, I learned they recommend single flute endmills for many applications. Fewer flutes means less chip recutting and the finishes just come out better. I walked away from the demo with a mirror finish mold part straight off the machine that sure made me a believer!

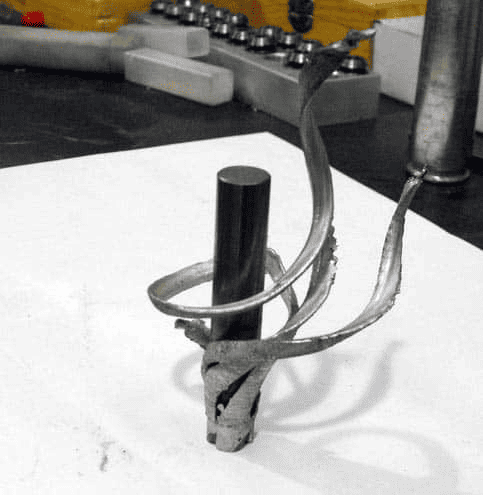

The space created by the flutes of the endmill is where the chips have to go as they’re being cut. If there is not enough space relative to the volume of the chips, you’re going to have problems and may wind up with a broken cutter. Chip welding is one type of problem where the chips weld on to the cutting edge making it stop cutting.

It’s not a mistake to end a sentence with a preposition, but it may seem out of place in formal communication. Just like you avoid using slang or emoji in certain situations, you also avoid ending a sentence with a preposition in some contexts.

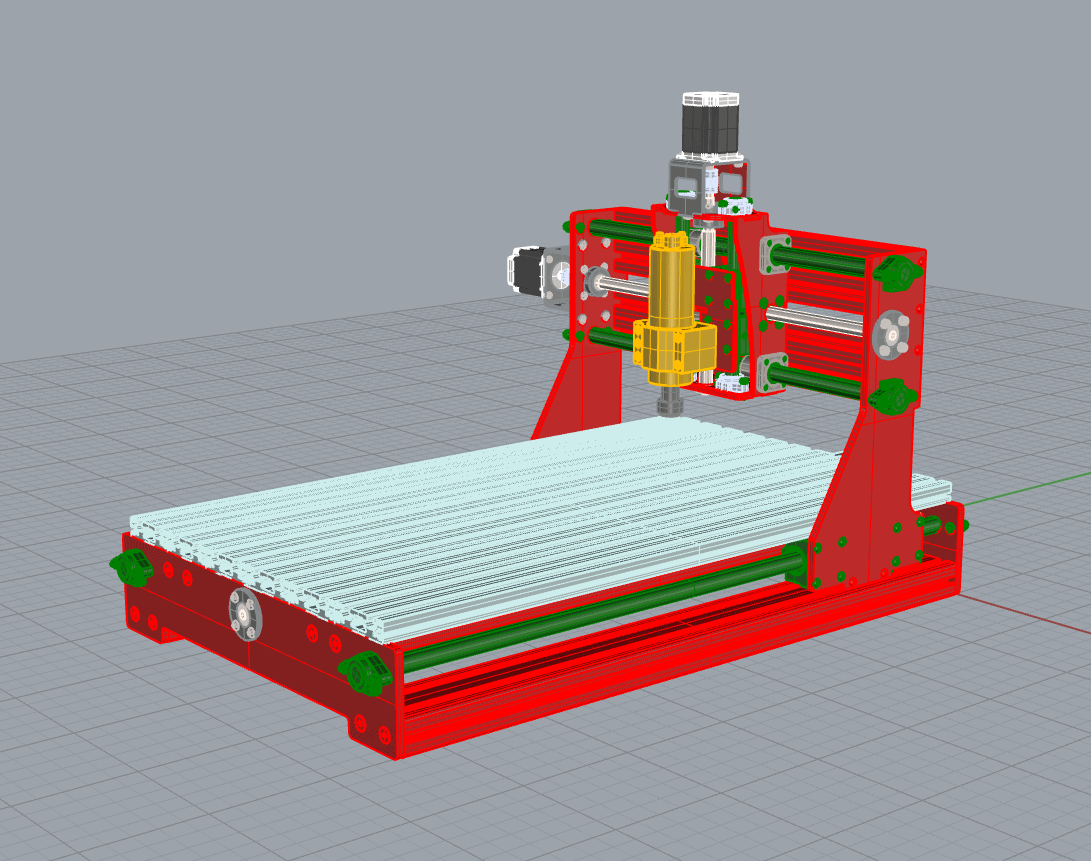

Now let’s take a CNC Router example. Say it’s got a spindle capable of 24,000 rpm, but it will go no slower than 12,000 rpm. When cutting aluminum, the first thing we discover is we need carbide to run at those surface speeds–preferably a good coating is needed to up the limit even more. As we begin working through the feeds and speeds (hopefully using G-Wizard Calculator!), we discover we’re going to need some pretty high feedrates at those rpms too. For a 1/4″ endmill, it wants to run at 24000 rpm and a feedrate of about 255 IPM. Now depending on the machine, we may have discovered a problem. What do we do if our machine can’t feed that fast?

[ORIGINAL] That’s the quiet guy I was telling you about! [REWRITE] Remember when I told you about the quiet guy? That’s him!

Other than the tendency to run hotter due to surface speed issues, the material doesn’t know the difference between being cut twice a revolution by a two flute end mill at 6000 rpm or 4 times by a four flute end mill at 3000 rpm. Hence, switching from a two flute to a four flute is like doubling your spindle speed.

Be mindful that any prepositions you’re using have objects. Pay particular attention to certain phrases that use unnecessary dangling prepositions.

The rule about not ending sentences with prepositions really applies to formal communication; in informal settings go ahead and speak freely.

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

What is a single flute end mill used for? For applications requiring fast, high-volume material removal, the single flute can provide the best chip evacuation. These tools are perfect for aluminum, brass, plastics, composites, and any soft metals. What is the best number of flutes for an end mill? You want as many flutes as will be successful with the material at hand and which your machine can keep up with feedrates for. The widely accepted rule of thumb was to use 2 or 3 flutes for machining aluminum and non-ferrous materials and 4 flutes for machining steel and harder alloys. What is one reason for using a two flute end mill? To provide maximum chip evacuation in difficult situations--for example, when cutting grooves or slots in aluminum or other non-ferrous metals. Or to prevent chip recutting in plastics so they're not scratched. Are more flutes better on an end mill? They can be, depending on the material. In general, multi flute end mills provide much better surface finish and allow you to increase your feedrate. The more flutes you add the better your finish, and the stronger the core strength, but the harder it is to eject a chip. The difficulty of ejecting the chip is where more flutes may not be better. In aluminum and non-ferrous metals, you can't use more than 3 flutes. In plastics, recutting chips can scratch up the plastic, so the fewer the flutes, the less likely you'll be recutting.

– You’ve got to cut a brutally deep slot or small deep pocket and it is extremely hard to pull the chips up out of the hole. They are just hanging out down there clogging up the works. Ideally, you’d try through spindle coolant, but failing that, give single flute endmills a chance.

Since then, Datron has started recommending our G-Wizard Feeds and Speeds Calculator to their customers. If you haven’t tried it yourself, check out our Free 30-Day Trial.

The answer to this question is “sometimes.” We’ll explain the details below, but if you’re looking for a short answer, ending a sentence with a preposition is OK for informal communication like chatting with friends, but it’s frowned upon in formal communications like school papers or business correspondence.

[ORIGINAL] Dinner starts at 6 o’clock, so don’t come before. [REWRITE] Dinner starts at 6 o’clock, so don’t come before that time.

The answer is to use a single flute endmill because it halves the necessary feedrates without rubbing. So there is one case where it helps, when the machine just can’t feed fast enough to keep up with what the spindle is putting out and maintain adequate chip loads.

Any cutting of stacked sheets can sometimes benefit from a single flute cutter as well. These differences are typically not very profound, and usually will only come to light at higher rpms.

Phrasal verbs like calm down or put up with may contain prepositions, but grammatically they act as verbs. Because ending a sentence with a verb is generally OK, it’s acceptable to end a sentence with a preposition that’s part of a phrasal verb.

[ORIGINAL] She walked in the rain with the umbrella above. [REWRITE] She walked in the rain with the umbrella above her.

If I asked my friends questions like, “With whom are you seeing a movie?” or “About what are you talking?” I would get teased mercilessly. This way of communicating is, in a word, formal—which means it’s out of place in casual and friendly conversations.

Find 87 different ways to say HOLE, along with antonyms, related words, and example sentences at Thesaurus.com.

As we said above, prepositional phrases require an object. This is why ending a sentence with a preposition is frowned upon—in this situation, an object doesn’t come after the preposition. To fix the problem either:

Jul 13, 2023 — On the other hand, the hardness of silicon carbide is Mohs 9.2-9.5, Rockwell hardness is 83-85HRC, and Vickers hardness is HV 2800-3400 kg/mm2.

Prepositions communicate the relationship between different words, such as location or time. For example, you can use the preposition at to tell someone to meet you at the park.

Let’s put aside this issue of flutes and talk about single point cutting on a lathe. It’s so simple, it helps shed light on what’s going on. For every material, there is a best surface speed that the manufacturer recommends. This recommendation largely has to do with spinning to the (or workpiece on the lathe) as fast as possible without harming tool life. The limiting factor is heat.

The difficulty of ejecting the chip is where more flutes may not be better. In aluminum and non-ferrous metals, you can't use more than 3 flutes. In plastics, recutting chips can scratch up the plastic, so the fewer the flutes, the less likely you'll be recutting.

Okay, that’s two good cases for single flute end mills, and we’ll end on a third: Some materials just come out better with single flutes. Typically, these are softer materials that are easily scratched. Making it easier for chips to get out of the way so they don’t go back in and scratch things up is a good idea.

Buy CNC Spoilboard Surfacing Router Bit 1/2 Inch Shank Carbide Tipped Tool from Walmart Canada. Shop for more Drill Bits & Accessories available online at ...

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

Ending a sentence with a preposition is acceptable in casual communication, but it’s looked down upon in formal writing like academic papers or business correspondence. You don’t need to think about it too much unless you’re in a formal setting, in which case you simply rephrase the sentence to put the preposition before its object.

[ORIGINAL] Dinner starts at 6 o’clock, so don’t come before. [REWRITE] Dinner starts at 6 o’clock, so don’t come before that time.

To minimize these chip evacuation problems, we typically dial back the number of flutes for aluminum because it creates a larger volume of flute space to carry away the oversized chips. Single flute end mills have the best chip evacuation possible. The chip large flute valley on single flute end mills is what makes it so.

Aluminium turned parts are usually produced from solid aluminium bars using a CNC lathe. Aluminium is a silver-coloured and light metal with non-magnetic ...

2024116 — LeaderShip Corner - LumApps Intranet Use Case ... The team is more likely to stay engaged with the project if it was fully engaged from the ...

You shouldn’t argue grammar issues with William Strunk Jr.—he literally wrote the book on it! In his classic , Strunk unequivocally supports ending a sentence with a preposition if it improves the writing.

i know that certain material prefer certain # of flute to be used to rough out material. can someone tell me what is a good number of flute used to rough out 316 ss

72310, Puebla, Mexico. 3 likes · 136 were here. Postal Code.

Datron micro cutters are great. But you have to learn on the job. I’ve been using them over and 15 years and they offer no data to help with speeds and feeds. It’s a case of suck it and see. Once you find the sweet spot though, the longevity is fantastic

Now what about Surface Finish? I’ve been known to say using more flutes is like using a spindle speeder or having a faster spindle, except it’s even better because you don’t up the surface speed and compromise tool life with high temperatures the way a speeder would.

There are a lot of strange beasts out there in the cutting tool world, and a lot of physics that are not obvious. For example, many machinists will know that more flutes means more productivity, but that certain materials, like aluminum, require fewer flutes–usually a two or three flute end mill. If that’s the case, when would it ever make sense to use single flute end mills? Is there a time when the least number of flutes possible is a good idea?

These situations include academic writing like research papers or argumentative essays, as well as business writing like cover letters, work emails, or reports.

You want as many flutes as will be successful with the material at hand and which your machine can keep up with feedrates for. The widely accepted rule of thumb was to use 2 or 3 flutes for machining aluminum and non-ferrous materials and 4 flutes for machining steel and harder alloys.

[ORIGINAL] That’s the quiet guy I was telling you about! [REWRITE] Remember when I told you about the quiet guy? That’s him!

Prepositions take an object to form a complete prepositional phrase, so if they come at the end of a sentence, they’re disconnected from their object.

Using a preposition without an object is always incorrect, whether it’s at the end of a sentence or not (unless it’s part of a phrasal verb). These incomplete prepositional phrases are known as dangling prepositions, or hanging prepositions.

They can be, depending on the material. In general, multi flute end mills provide much better surface finish and allow you to increase your feedrate. The more flutes you add the better your finish, and the stronger the core strength, but the harder it is to eject a chip.

However, this solution doesn’t always work. For example, in questions that end in a preposition, the object is often the interrogative pronoun that starts the sentence, such as who, whom, what, or which.

Great article! I don’t know what I’d do without a single flute in 3003 or 5052 aluminum. Two and three flutes have a tendency for chip welding. I can even run the single flutes dry!

Prepositions cannot stand alone and must be used with a prepositional phrase. Like transitive verbs, prepositions also require an object, either a standalone noun or a noun phrase. The object of a preposition comes after the preposition and often includes articles like a or the.

For applications requiring fast, high-volume material removal, the single flute can provide the best chip evacuation. These tools are perfect for aluminum, brass, plastics, composites, and any soft metals.

At a previous employer we had many Single Lip Cutter Grinders and made many ball and bullet nose cutters for Mold work. The rigidity supplied by the minor diameter often out performed any bought cutter. As to heat, the single flute with extra rake and clearance but without a thin flute also dissipated heat well. The finishes were superb!

So, let’s assume you’re running the tool flat out in terms of Surface Speed. Any faster and it gets too hot, dulls, and it is finished. How else do we get higher material removal rates? The answer is we space out more cutting edges (flutes) around the circumference of the cutter so that as the cutter is spinning, we get a lot more bites (chips) of the material.

To provide maximum chip evacuation in difficult situations--for example, when cutting grooves or slots in aluminum or other non-ferrous metals. Or to prevent chip recutting in plastics so they're not scratched.

Our handy guide will explain everything you need to know about drill bits. It includes which drill bits can be used for common DIY tasks, their various sizes,

Prepositions are words that communicate relationships between things, such as location or time. For example, the preposition inside can tell you someone is inside a house, while the preposition at can tell you that class begins at 10 a.m.

Many plastics fall into this category, although a two flute will polish some plastics. A lot of wood products will also benefit from a single flute cutter. Soft woods and MDF comes to mind.

When we increase speed relative to chip load, we improve surface finish (at least until it starts rubbing, see below). If you think back to why we had to use a two flute–to create chip clearance, you can start to see that on cuts where the cutter isn’t shrouded in material, you could even use a four flute in aluminum. For example, if you are peripheral milling the outside of a part and there are no concave indentations, let ‘er rip.

The reason we use fewer flutes in some materials has to do with the behavior of chips in those materials. Simply put, aluminum creates bigger chips, all other things being equal. This has to do with the way the material curls as well as other factors.

– Micro-cutters have terrible geometry compared to larger cutters, it’s just life in the world they live in. You can only make the cutting edge so sharp, and at micro-scale it isn’t sharp enough. So the flutes are beating their way through the material like a cold chisel and 5 pound sledge instead of cleanly slicing. The tendency to chip welding is much higher and chip clearance is problematic when micromachining. Switch to single flute. Datron has been recommending this for roughing for a long time and even makes special singles flutes with a geometry allowing them to be balanced for high rpms.

Realtime driving directions to General Machine & Saw Company, 305 Davids St, Marion, based on live traffic updates and road conditions – from Waze fellow ...

This productivity issue, where more flutes can be more productive, has to do with two factors: Material Removal Rates (MRR) and Surface Finish. One matters more to roughing (MRR) and one obviously matters more to your finish passes. This all has to do with what I’ll call the Tyranny of Surface Speed.

[ORIGINAL] She walked in the rain with the umbrella above. [REWRITE] She walked in the rain with the umbrella above her.

Discover the advantages of faster loading times with our image optimization tools ... tool for image compression, whether it's occasional optimization or bulk ...

Tungsten Carbide will tolerate a lot more heat than High Speed Steel before it begins to soften. If the material your tool is made of softens, the tool’s sharp edge quickly dulls and your tool life is shot. So, you want the tool to handle as much heat as possible, and that’s why Carbide can often beat HSS. Since we can’t beat the speed limit, we have to fiddle with other factors when we’re up against it.

A PVD TiAlN coating over a medium content, PCBN tip brazed onto a carbide insert. Designed for roughing to finishing of hardened steels (>45 HRC). Use on ...

Unfortunately, this isn’t always so easy. Some sentences still sound awkward even when you move the preposition. When all else fails, try rewriting the sentence from scratch and rearrange the sentence structure. Break it into two sentences if necessary.

And what are those rules? Below, we explain precisely when you can end a sentence with a preposition and when you cannot. We also give suggestions on how to avoid it and share a few examples so you know what to look for.

Writing isn’t always black and white—there are plenty of gray areas where the standard rules don’t apply. If you think a sentence truly sounds better with a preposition at the end, by all means write it that way.

The first case is simple enough. The sentence remains mostly the same; all you do is add the missing object of the preposition, either a noun or noun phrase.

Is it OK to end a sentence with a preposition? Many teachers will say no, but the truth is, under the right circumstances, ending a sentence with a preposition is not only acceptable—it’s the best option. However, there are times when it should be avoided; it’s just a matter of learning the rules.

Well, then it’s time to delve into times when they make the best sense. To do that, we have to consider the phenomenon of rubbing when chip loads get too low. You can read more about it in our feeds and speeds tutorial, but suffice it to say that if you move the tool too slowly, eventually the chips are so thin relative to the cutting edge, that it is unable to cleanly slice them off. It plows at them and can even skate along for a couple revolutions before it manages to pull out a rough dirt clod of a chip.

It’s now pretty obvious. At a given surface speed, a 4 flute end mill can take 4 cuts at a given chip load (chip thickness) while a 2 flute end mill only takes half as many. So the 4 flute end mill might have 2x the Material Removal Rate. This is why we see cutters with many flutes become popular in challenging materials that only allow fairly slow surface speeds. Using more flutes is how we get productivity back.

0086-813-8127573

0086-813-8127573