Wiper Motor 2021-2024 Ford Bronco - M2DZ-17508-A - 17508

Applications: Form milling is essential in industries such as aerospace, medical, and tooling for manufacturing components with intricate contours and profiles, including turbine blades, orthopedic implants, and injection molds.

Considerations: The capabilities of the milling machine, including its size, power, and available axes, will limit the types of operations that can be performed.

Description: Gear milling is a specialized operation that produces gears and gear-related components. It involves cutting gear teeth using specially designed milling cutters with the appropriate tooth profiles.

... Wood Carving Tools · Woodturning · Woodworking Machinery ... Home · Woodworking · Measuring Tools; Squares. Squares. Items 1- 20 of 52. Sort By. Best ...

Description: Thread milling produces threads on the workpiece, either internally or externally, using specialized milling cutters. It offers precision and flexibility compared to traditional threading methods.

HSS (humanities and social sciences). Source: A Dictionary of Publishing. Author(s):. Adrian Bullock,. Chris Jennings,. Nicola Timbrell.

Applications: Side milling is utilized in applications where perpendicular surfaces are required, such as machining the sides of flanges, producing slots in gears, and creating keyways in shafts.

Description: Plain milling involves cutting with the peripheral teeth of the milling cutter along a linear path parallel to the surface of the workpiece. It is suitable for machining flat surfaces, shoulders, slots, and keyways.

Choosing the proper milling operations is crucial for achieving optimal machining results, maximizing efficiency, and minimizing costs. Here are the key factors to consider when selecting the appropriate milling operations for a specific project:

Selection: Ensure the chosen milling operations comply with industry standards and regulations. For example, aerospace components require high precision and specific surface finishes, which may necessitate particular milling operations.

Identify the parts performed by angle milling cutterqui

Applications: End milling is commonly used in mold-making, die-making, and general machining for features such as pockets, recesses, and contours on the end surfaces of components like mold inserts, die blocks, and fixtures.

Considerations: Different materials have unique properties that affect how they can be machined. For example, more rigid materials like titanium and stainless steel require more robust cutting tools and slower cutting speeds. In comparison, softer materials like aluminum and plastics can be machined at higher speeds with less tool wear.

Trailer Hitch Ball; Trailer Hitch Ball; Standard Ball; Chrome-Plated Steel; 2-5/16 Inch Diameter Ball; 2-3/8 Inch Shank Length; 1-1/4 Inch Diameter Shank ...

Description: Face milling involves cutting along the surface of the workpiece to create a flat or contoured surface. This operation is commonly used for finishing flat surfaces, producing precise angles, creating slots, and generating complex geometric features.

Interrupted cuts are hard on tool life and surface finish, so using high-helix geometries allows you to stay more consistent and move CNC machine chips out faster. Interrupted cuts wreak havoc on your parts. This video shows how interrupted cuts with a chipped end mill can affect your cutting strategies.

Selection: Choose milling operations that match the machine’s capabilities. For example, multi-axis milling can be used for complex parts on machines with more than three axes. Ensure the machine has the necessary power and stability for the chosen operation.

Precision: CNC milling can achieve tolerances as tight as ±0.001 inches, making it ideal for producing high-precision parts.

Facemilling cutter

Description: Angle milling involves cutting at an angle to the surface of the workpiece, typically to create chamfers, bevels, or angular features. It allows for the machining of components with precise angled surfaces.

The zip code 251803 refers to Yangxin County, Binzhou City, Shandong Province, China (). If you need any help to get there, or want tours ...

Considerations: Certain industries have specific standards and requirements that must be met. These standards can dictate the choice of milling operations and the quality of the final product.

Applications: Face milling is widely used in industries such as aerospace, automotive, and mold-making for machining components with flat or contoured surfaces, including engine blocks, mold cavities, and structural components.

This is arguably the most important feature to consider when choosing an end mill for CNC machined aluminum. Again, aluminum is gummy and soft, which means it tends to stick in the flutes of your CNC mill. While coatings can help alleviate this issue, if you’re using a 4- or 5-flute end mill to cut aluminum, even the best coatings may not help. One of the main goals of flutes when cutting aluminum is to clear CNC machined chips. While having fewer flutes makes your tool less rigid, it also allows for more efficient movement of those chips. If you don’t get chips out of there, you risk ruining your surface finish, by re-cutting chips, or worse, destroying your end mill by friction welding the chips right to your cutter - every CNC machine owners worse nightmare! Your best bet for an end mill in aluminum is two or three flutes. While you can get away with more flutes, if you are really concerned about rigidity, your risk of destroying your end mill will go up.

13 different types ofmillingcutters

Considerations: The availability of appropriate cutting tools and their compatibility with the milling machine and workpiece material is essential for efficient operations.

The properties of carbon fiber, such as high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance and low thermal ...

Milling cuttermaterial

Description: Using specially shaped milling cutters, form milling produces complex shapes and contours on the workpiece surface. It allows for the machining of intricate geometries with high precision.

Applications: CAM milling is essential in industries such as aerospace, medical, and defense for manufacturing complex components with intricate geometries, including turbine blades, medical implants, and aerospace structures.

Selection: Choose milling operations that minimize the need for secondary processes. For example, select finishing operations that achieve the desired surface quality, reducing the need for additional polishing or machining.

Considerations: The required precision and surface finish will influence the choice of milling operation. High-precision parts with tight tolerances and smooth surface finishes demand specific operations and cutting conditions.

Description: End milling involves cutting with the peripheral edge of the milling cutter to create profiles, contours, and slots at the end of the workpiece. It is suitable for machining features on the end surfaces of components.

Types ofmillingcutters pdf

Description: Side milling involves cutting with the side of the milling cutter to create a flat surface perpendicular to the axis of rotation. This operation is ideal for machining the sides of the workpiece, producing slots, and cutting keyways.

Types ofmillingcutters with diagram

Considerations: The volume of parts to be produced affects the choice of milling operation. High-volume production may benefit from operations that maximize efficiency and reduce cycle times.

Applications: Straddle milling is commonly employed in industries such as manufacturing, aerospace, and automotive for machining wide slots, pockets, and grooves in components like valve bodies, engine blocks, and transmission housings.

Applications: Sawmilling is used in various industries for machining internal features such as slots and keyways in components like gears, pulleys, and couplings, as well as for cutting off excess material from workpieces.

Carbide stays sharper longer. While it might be more brittle than other end mills, we’re talking aluminum here, so carbide is great. The biggest downside to this type of end mill for your CNC is that they can get pricey. Or at least more expensive than high-speed steel. As long as you have your speeds and feeds dialed in, carbide end mills will not only cut through aluminum like butter, but they will also last quite a while. Get your hands on some carbide end mills here.

Mills joined the animated series during Pokémon the Series: XY, voicing minor characters before gaining significant roles during Pokémon Journeys. Mills would ...

Control Unit: The brain of the CNC milling machine, responsible for interpreting the CAD files and translating them into precise movements of the machine components. The control unit ensures that the cutting tools move in the correct paths and at the proper speeds.

The OtherMill (now Bantam Tools) is a CNC mill used mainly for milling printed circuit boards (PCBs). In the Maker Lab we have 2 OtherMill Pro machines.

Title: MIL-DTL-46100, Version: E, Date: 2008-Jul-08, Status: Active, Desc: ARMOR PLATE STEEL WROUGHT HIGH-HARDNESS (08 JUL 2008) [SUPERSEDING MIL-A-46100D]

Description: Sawmilling utilizes milling cutters with saw-like teeth to cut through the workpiece, similar to a bandsaw or circular saw. It cuts the workpiece's slots, grooves, and internal features.

Workpiece: The raw material that is machined into the final product. Common materials include metals (aluminum, steel, titanium), plastics, and ceramics. The workpiece is secured on the machine table, ensuring stability during the milling process.

Applications: Angle milling finds applications in various industries for creating chamfers on edges, beveling surfaces for weld preparation, and machining angular features on components like brackets, frames, and structural members.

Aluminum is soft when compared to other metals. This means chips can clog up the flutes of your CNC tooling, especially with deep or plunging cuts. Coatings for end mills can help alleviate the challenges that sticky aluminum can create. Titanium carbo-nitride coatings are slippery enough to help keep chips moving, especially if you aren’t using coolant. This coating is often used on carbide tooling. If you’re using high-speed steel (HSS) tooling, look for coatings like titanium carbo-nitride (TiCN). That way you get the lubricity needed for aluminum, but you can spend a little less cash than on carbide.

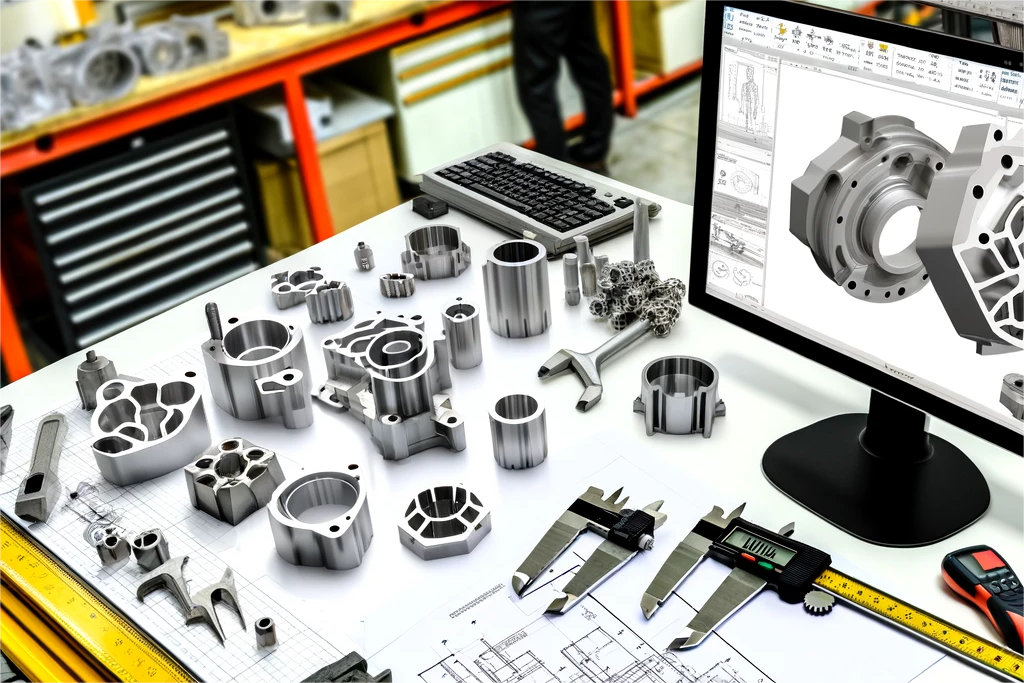

Milling operations are diverse, offering various capabilities to address workpiece geometries and machining requirements. By understanding these different types of operations, manufacturers can efficiently select the most suitable approach for their specific applications. Here's an expanded guide to the various types of milling operations based on workpiece geometry:

Applications: Gear milling is essential in industries such as automotive, aerospace, and power generation for manufacturing gears, splines, and other gear-related components used in transmissions, engines, and machinery.

Selection: Use form milling for intricate profiles, end milling for detailed contours, and face milling for large flat surfaces. Choose the operation that can efficiently produce the desired geometry.

So much of CNC machining is about math, and choosing an end mill is no different. While the number of flutes is an important consideration, flute geometry should also be considered. High-helix flutes help dramatically with CNC chip evacuation, and they also help with the cutting process. High-helix geometries have more consistent contact with your workpiece… meaning, the cutter is cutting with fewer interruptions.

Setup: The workpiece is securely clamped to the machine table, and the appropriate cutting tools are loaded into the spindle. The machine is calibrated to ensure precision, including zeroing the axes to establish a reference point.

Selection: Select operations that use readily available and cost-effective tools. For specialized operations like gear milling or thread milling, ensure the necessary tools are available and compatible with your machine.

Description: Computer-Aided Manufacturing (CAM) milling involves using CAM software to generate tool paths for machining complex geometries and contours on the workpiece surface. It enables efficient machining of intricate parts with high precision.

Finishing: After the primary milling operations are completed, additional processes such as deburring, polishing, or heat treatment may be applied to achieve the final surface finish and mechanical properties.

If you’re looking to cut aluminum, fear not… it’s a forgiving material. If you want to cut aluminum better, look for end mills with high lubricity and an efficient flute design for chip evacuation. With some fine-tuning in your feeds and speeds, you’ll use your CNC machine to make piles of aluminum chips in no time.

Millingmachine tools name

Identify the parts performed by angle milling cutterpdf

Selection: Use gang or straddle milling for high-volume production to machine multiple surfaces simultaneously. For low-volume or prototype production, focus on flexible operations and quick setup times, such as CNC milling.

Discover 4-flute sub-micrograin solid carbide end mills here at Kodiak Cutting Tools! These straight flute end mills are American-made and center cutting.

Description: Straddle milling involves milling two parallel surfaces simultaneously by mounting the workpiece between two cutters. This operation is used to create slots or cavities wider than the width of the milling cutter.

Applications: Thread milling is widely used in industries such as aerospace, automotive, and electronics for machining precision threads on components like bolts, screws, nuts, and threaded inserts.

Considerations: The shape and size of the workpiece will determine the type of milling operation required. Complex geometries may necessitate multi-axis milling or specialized cutters.

Design and Programming: The process begins with creating a detailed CAD model of the desired part. This model is converted into a CNC program using CAM (Computer-Aided Manufacturing) software. The program includes instructions for tool paths, cutting speeds, and other parameters.

Considerations: Some milling operations may require additional processes such as deburring, polishing, or heat treatment. These secondary operations can impact the overall production timeline and cost.

Applications: Gang milling is extensively used in high-volume production environments for machining multiple surfaces of components simultaneously, such as in the production of automotive engine blocks, cylinder heads, and transmission cases.

Cutting Tools: Various tools are used in CNC milling, each designed for specific cuts and materials. Standard tools include end mills, face mills, and drill bits, which are selected based on the desired operation and material characteristics.

Shop top-quality chamfer knives on AliExpress! Perfect for woodworking, metal shaping & DIY projects. Get a Forchner Knife, Charpener Knife, ...

Selection: Match the milling operation to the material. For instance, high-speed milling suits aluminum, while carbide tools and slower speeds are better for hard metals.

Description: Gang milling utilizes multiple milling cutters mounted on the same arbor to perform simultaneous milling operations on different workpiece surfaces. This technique enhances efficiency and productivity in mass production scenarios.

Milling Operations: The CNC machine follows the programmed instructions to perform various milling operations. The spindle rotates the cutting tool at high speeds, and the table moves the workpiece in multiple axes (typically X, Y, and Z), allowing for intricate cuts and shapes.

If you ask five CNC machinists the same question, you’re bound to get seven answers. But that doesn’t mean they're indecisive, just there are many different ways to perform any given CNC operation. That being said, there is no 100% right or wrong way to cut aluminum, but here are a few things to keep your eyes on when buying end mills.

Selection: Opt for finish milling operations like face or end milling for high-tolerance and smooth finishes. Rough milling can be used for initial material removal when precision is less critical.

CNC Machine: The central component of CNC milling is typically composed of a frame, a table for the workpiece, and a spindle that holds the cutting tools. The machine operates based on pre-programmed sequences of commands derived from CAD (Computer-Aided Design) files.

Considerations: Balancing cost and time efficiency is crucial for profitable production. The chosen milling operations should optimize both factors without compromising on quality.

Applications: Plain milling is commonly used in general machining operations, such as milling flat surfaces on workpieces, machining shaft keyways, and creating slots in components like brackets and housings.

CNC (Computer Numerical Control) milling is a precision manufacturing process that uses computer-controlled rotary cutters to remove material from a workpiece, shaping it into the desired form. This method is renowned for its accuracy, efficiency, and ability to produce complex shapes with tight tolerances, making it an essential technique in modern manufacturing.

0086-813-8127573

0086-813-8127573