Wire Cable Cutters Set (Heavy Duty Industrial Grade 4 ... - types of wire cutters

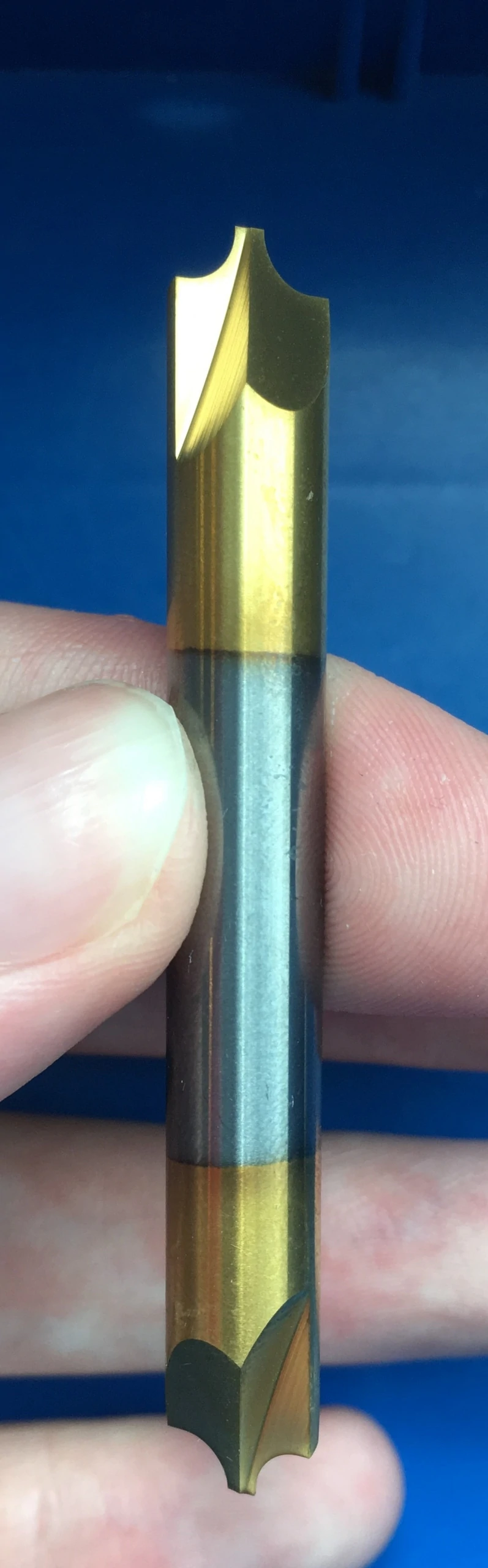

A Corner Rounding End Mill is typically used to add a specific radius to a workpiece, or in a finishing operation to remove a sharp edge or burr. Prior to selecting your tool, mull the following considerations over. Choosing the right tool will result in a strong tool with a long usable life, and the desired dimensional qualities on your part. Choosing wrong could result in part inaccuracies and a subpar experience.

The offset boring is an attachment that fits the milling machine spindle and permits most drilled holes to have a better finish and greater diameter accuracy.

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

Putting a full radius on a part has the potential to leave a step or an over-cut on a workpiece. This can happen if the tool isn’t completely dialed in or if there is minor runout or vibration. A slight 5° flare on the pilot and shoulder blends the radius smoothly on the workpiece and avoids leaving an over-cut.

The best corner rounding end mill varies from job-to-job. Generally speaking, opting for a tool with the largest pilot diameter possible is your best bet, as it has the most strength and requires less power due to its larger effective cutter diameter. A flared Corner Rounder is preferred for blending purposes if the workpiece is allowed to have an incomplete radius as this allows more forgiveness and can save on set up time. If not, however, an unflared Corner Rounder should be utilized. As is often the case, choosing between number of flutes boils down to user preference, largely. Softer materials usually require fewer flutes. As material gets harder, the number of flutes on your tool should increase. print

These tools are often offered in 2, 3, and 4 flute styles. 2 flute styles are normally used for aluminum and non-ferrous materials, although 3 flutes is quickly becoming a more popular choice for these materials, as they are softer than steels so a larger chip can be taken without an impact on tool life. 4 flutes should be chosen when machining steels to extend tool life by spreading out the wear over multiple teeth. 4 flute versions can also be run at higher feeds compared to 2 or 3 flute tools.

Choosing between a Corner Rounding End Mill and a Back Corner tool boils down to the location on the part you’re machining. A Back Corner Rounding End Mill should be utilized to put a radius on an area of the part facing the opposite direction as the spindle. While the material could be rotated, and a front Corner Rounding End Mill used, this adds to unnecessary time spent and increased cycle times. When using a Back Corner Rounding End Mill, ensure that you have proper clearance for the head diameter, and that the right reach length is used. If there is not enough clearance, the workpiece will need to be adjusted.

Speed and Feed Charts. Enter the series number of the Guhring tool you which to find speeds and feeds for. Find speeds and feeds chart by: Series Number.

5mm Shank 160mmL High Speed Cobalt Tool Bit. Tool Bit. Fastenal Sku: 922372708. User Icon Sign In to view pricing. -. +. ADD TO CART. Availability ...

Microcut is a manufacturer of Premium Quality Carbide End Mills and Special Application Rotary Cutting Tools for industrial and medical applications.

I have a Mills Double Eagle & 4 Column machine and neither of those locks worked. The lock center hole mounting screw spacing is 1 1/8". I wonder if Pace had ...

A flared Corner Rounding End Mill leaves an incomplete radius but allows for more forgiveness. Additionally, this tool leaves a clean surface finish and does not require a second finishing operation to clean leftover marks. An unflared corner radius leaves a complete radius on the workpiece, but requires more set-up time to make sure there is no step.

Our Smart Feed and Speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for Milling, Turning, Drilling and Grooving.

It is always fun when reading about CNC machines as this teaches me so much more. I really didn’t know Corner Rounding End Mill Decisions existed know I will have to study about it in detail. Thanks to the writer, great article.

They work extremely well in Titanium. We suggest using our 4 flute Corner Rounder with our AlTiN coating in the desired radius you need.

The pilot diameter (D1 in the image above) determines the tool’s limitations. When pilot diameters are larger, the tool is able to be run at lower speeds. But with smaller pilot diameters, the tool can be run faster because of its larger effective cutter radius. The effective cutter diameter is determined by the following equations depending on the radius to pilot ratio:

BXW4053 KIT, Hitch Ball 2 5/16" X 1 1/4" Shank 20K Chrome.

Larger pilot diameters also have more strength than smaller pilot diameters due to the added material behind the radius. A smaller pilot may be necessary for clearance when working in narrow slots or holes. Smaller pilots also allow for tighter turns when machining an inside corner.

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

Drill, countersink or counterbore all in one operation to a high degree of accuracy. This six piece drill/countersink/counterbore features 1/4" hex shanked ...

Aug 26, 2024 — How deep the tool cuts in the workpiece material in one turn refers to the depth of the cut in the milling process. The cutting depth is usually ...

221K Followers, 877 Following, 5748 Posts - Magnuson Superchargers (@magnusonsuperchargers) on Instagram: "Magnuson's industry leading OEM ...

0086-813-8127573

0086-813-8127573