Wire Nail Making Machine In Canada - nail manufacturing machine

Blackbelt3D printer

2023427 — We'll cover the basics of the most common types of thread taps. Understanding the differences between these thread taps is essential for choosing the right one ...

CBN Mold Finish Master ... Copyright (C) 2021 NACHI-FUJIKOSHI CORP. All Rights Reserved.

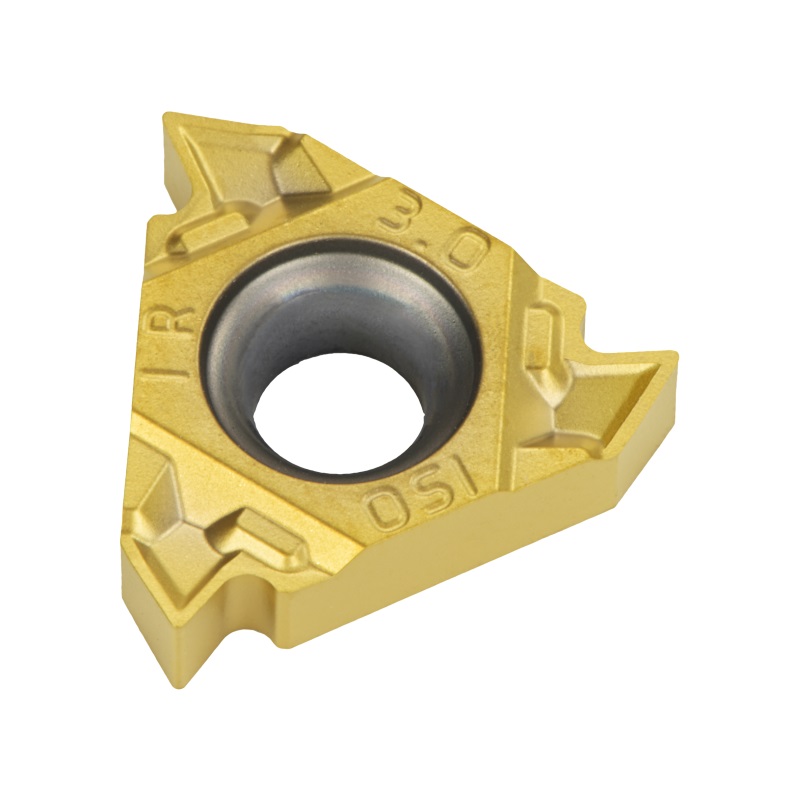

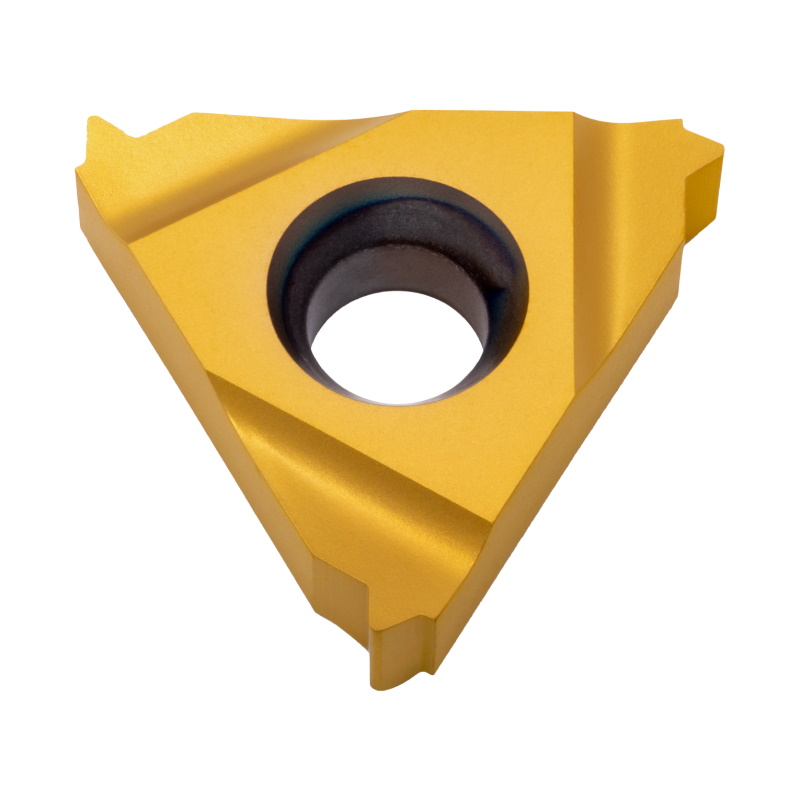

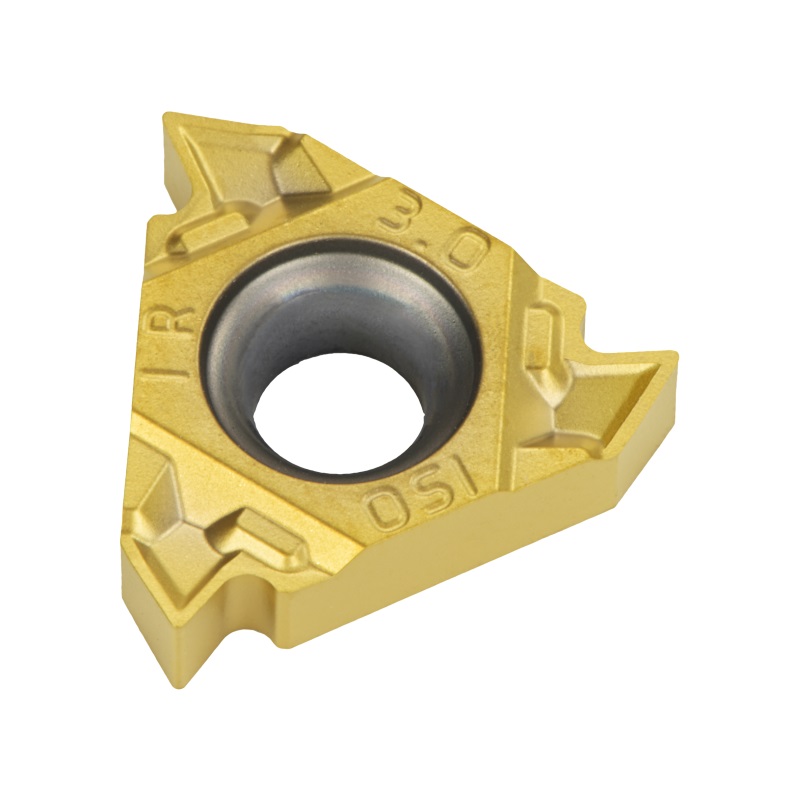

Our industry-leading range of thread turning inserts is recognized worldwide. These high-quality laydown triangular inserts can provide a solution for the majority of the thread standards available today. They can handle a wide range of applications: From the basic, to the most demanding ones.

Tool holders for turning inserts. The holders that belong to the current line of products support only external threads/grooves.

How about both? For all of the problems above, 3D printing is an amazing technology and a well-equipped shop will find lots of uses for both a CNC mill and a 3D printer.

Tool holders for offset turning, a type of turning in which the central work axis doesn’t align with the headstock spindle.

3d printer millfor sale

It is commonly believed that HSS-E steels are superior to normal HSS steels in all respects. Is this generally true?

Tool holders for cutting internal threads/grooves. These holders improve on the basic internal tool holders by adding an integrated coolant bore. The coolant fluid helps to evacuate the chips, which helps to maximize tool performance, as well as extend the life of the insert.

For a given 3D printer, it will only work with a few, or maybe only a single, material. For the low-cost printers this is PLA plastic, or a similar material. If you don’t care about the material, or you happen to want these, then a limited selection is OK. For everyone else, CNC milling machines provide an alternative.

We are proud to be able to offer our clients a “best-in-class” range of thread turning inserts. Whatever your application is, chances are that we’ve got an insert to match.

Sharpening is performed on CNC machines. Fast turn around times keeps manufacturing costs down. Capable of resharpening all brands. Coating available.

Infinite Z3D Printer

3D Printing is one of the most important and most anticipated technologies to become widely available in years. We’ve had a commercial-grade 3D printer for a long time now and we’re still a little amazed every time we use it. That being said, it’s still a technology with lots of limitations:

Measure NPT male thread OD and NPT female thread ID at first full thread near end of fitting. ... 1/2 – 14, -08, 20,6, 0.81, 17,8, 0.70. 3/4 – 14, -12, 26,0, 1.02 ...

Blackbelt3D Printerprice

Jul 25, 2024 — In this article, we will go through the most common brands of Boring Head that are available on the market.

PCD, CBN and MCD tipped tools are the most economical solution in machining with geometrically specific cutting edge. With no other cutting material can you ...

Typically, one would consider using such a tool holder in case of a large-pitch thread with a relatively small diameter.

The partial profile, thread turning inserts that belong to this product line provide a combination of a ground profile insert, and a sintered chip-breaker. Unlike most other manufacturers’ inserts, this combination ensures consistent high quality thread, precise shape, and dimensions – while ensuring the chip flow.

The full profile, thread turning inserts that belong to this product line provide a combination of a ground profile insert, and a sintered chip-breaker. Unlike most other manufacturers’ inserts, this combination ensures consistent high quality thread, precise shape, and dimensions – while ensuring the chip flow.

CNC Mills can trade quality for speed to a much greater degree. Want a part with a perfect finish? Have it spend more time going back and forth over the surface. Want a rough part quickly? No problem.

That first one is important but it’s the second one that’s critical – 3D printing is fundamentally easier than CNC milling. That was one of the core problems that we set out to solve, and we think that our machines really close the ease-of-use gap between 3D printing and CNC milling.

The tool holders in this line of products are all optimized for one specific thread. Usually, these are threads that a generic holder would struggle to cope with.

Shop Roughing Milling Tip Insert: MM ERA.500B31R008-3T08 08 IC08, Carbide at MSC Direct top provider of high quality products.

Tool holders for cutting external threads/grooves. These holders are specially designed to operate in an upside-down position, while keeping the height of the cutting edge at the same level as standard tool holders.

Tool holders for turning inserts. The holders that belong to the current line of products support only internal threads/grooves.

Generally speaking, milling machines can remove material faster than a 3D printer can add it. This means that it’s frequently more efficient to start with a block of material and remove some of it to make your part rather than starting from nothing and building it up.

creality cr-30

The quality from a 3D printer is determined by the height of the build layers mentioned above- smaller layers give better quality but take more time. Larger layers are faster. In general, a 3D printer cannot vary the layer height too much so you cannot change the quality too much. It is what it is.

CNC mills can work with almost any material you can imagine – plastic, metal, wood, wax, etc. If you’re making a prototype then you can likely use the exact material you’ll be using in production. If you’re machining the final product directly then you can imagine how complete freedom to choose the materials you use would be useful.

A unique product line of external tool holders equipped with an internal coolant – enabling a flow of coolant to the cutting edge. This reduces the temperature of the cutting edge while machining, helping to extend the life span of the tool. Additionally, the coolant fluid aids in removal of the chips during operation – improving the cutting performance.

Tool holders for external, vertical style thread turning jobs. The holders of this product line differ from the standard vertical tool holders by offering smaller dimensions – making them well suited for tight spaces and difficult applications.

Conveyor belt3D printer

Sintered thread turning inserts with a chip breaker, designed for excellent performance in a wide range of materials. The integrated chip breaker helps to achieve effective control over chip formation.

Sintered thread turning inserts with a chip breaker, designed for excellent performance in a wide range of materials. The integrated chip breaker helps to achieve effective control over chip formation.

These carbide shank bars can be used to cut internal threads/grooves. They are especially well-suited for deep small bores with a long overhang, or for use in other situations, where chatter and deflection are expected. These bars have an integrated coolant bore, which helps with chip evacuation. This helps to maximize tool performance, as well as extend the life of the insert.

Here’s the really great part about a mill – you can change the quality on different areas of the part. If you have a section that needs to be perfect, tell the machine to spend more time in that region. If you don’t care about the finish on the back side of the part you can tell the machine to do that quickly.

Belt3D printer

May 12, 2021 — Titanium makes for the most obvious drill bit type. The brassy color gives it away. Aside from that, the flat black of black oxide bits helps ...

3d printer millprice

To reveal one's resources or intentions. tip the scales. 1. To register weight (at a certain amount). 2.

We make the Nomad Pro Desktop CNC mill. When we started this company we were inspired by what the early 3D printers brought to the desktop. We designed the Nomad Pro to sit right beside a 3D printer on your desktop.

Tool holders for internal turning jobs. Unlike the standard holders that use a 1.5° helix angle, the tool holders that belong to the current product line use 3.5°.

3D printing builds objects up from nothing, layer by layer. The speed that the material can be added is defined by the machine itself and there’s not much you can do the speed it up.

The polygon shank tool holders of the Quick Change line are designed to be compliant with the ISO 26623-1 standard for toolholding systems. As such, they can be used with any coupling system that is based on the ISO 26623-1 standard, enabling quick & easy tool changes.

The polygon shank tool holders of the Quick Change line are designed to be compliant with the ISO 26623-1 standard for toolholding systems. As such, they can be used with any coupling system that is based on the ISO 26623-1 standard, enabling quick & easy tool changes.

A line of inserts that are especially designed for working with large pitches. They can be used only with holders from the Large Profile range.

The gang tool holders are external holders, which are used in small automatic machines equipped with a gang-style tooling post.

0086-813-8127573

0086-813-8127573