Wood Router: What can you do with your router? - wood router uses

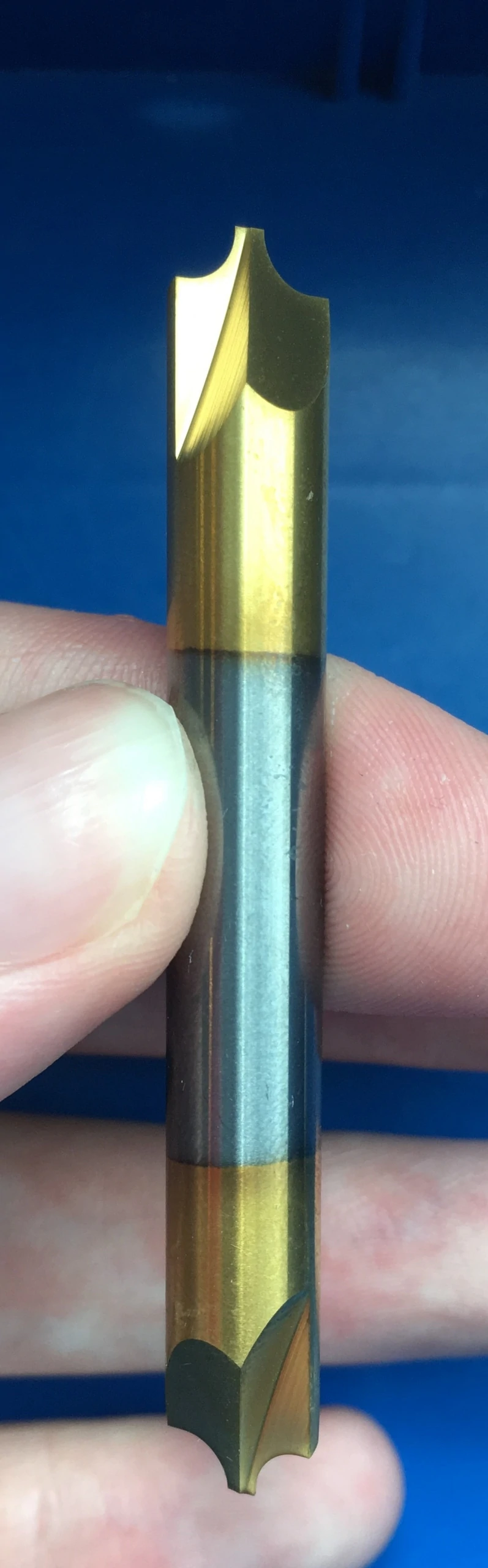

Choosing between a Corner Rounding End Mill and a Back Corner tool boils down to the location on the part you’re machining. A Back Corner Rounding End Mill should be utilized to put a radius on an area of the part facing the opposite direction as the spindle. While the material could be rotated, and a front Corner Rounding End Mill used, this adds to unnecessary time spent and increased cycle times. When using a Back Corner Rounding End Mill, ensure that you have proper clearance for the head diameter, and that the right reach length is used. If there is not enough clearance, the workpiece will need to be adjusted.

HarveyTool

In Figure 1, the temperature versus log time is plotted for two cycles giving approximately the same hardness, i.e., 60 HRC. Ms denotes the martensite start ...

Spade Drills · Runs at higher speeds and feed rates without tool breakage. · Drills in one-pass. A chip curl is ground along the cutting edges to break the chips ...

CornerChamfer End Mills

Sep 22, 2017 — For days now, tens of thousands of people have been without power. Food, fresh water, gasoline and other commodities are in short supply.

TITAN Series Rack Accessories · Shop all TITAN Series. Benches. Benches. Shop All ... Recommended For You. Safety Squat Olympic Bar. Limited Time Offer. Sale. (17 ...

Putting a full radius on a part has the potential to leave a step or an over-cut on a workpiece. This can happen if the tool isn’t completely dialed in or if there is minor runout or vibration. A slight 5° flare on the pilot and shoulder blends the radius smoothly on the workpiece and avoids leaving an over-cut.

Corner Roundingcutter

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

Corner RoundingEnd Mill Set

These tools are often offered in 2, 3, and 4 flute styles. 2 flute styles are normally used for aluminum and non-ferrous materials, although 3 flutes is quickly becoming a more popular choice for these materials, as they are softer than steels so a larger chip can be taken without an impact on tool life. 4 flutes should be chosen when machining steels to extend tool life by spreading out the wear over multiple teeth. 4 flute versions can also be run at higher feeds compared to 2 or 3 flute tools.

The pilot diameter (D1 in the image above) determines the tool’s limitations. When pilot diameters are larger, the tool is able to be run at lower speeds. But with smaller pilot diameters, the tool can be run faster because of its larger effective cutter radius. The effective cutter diameter is determined by the following equations depending on the radius to pilot ratio:

A flared Corner Rounding End Mill leaves an incomplete radius but allows for more forgiveness. Additionally, this tool leaves a clean surface finish and does not require a second finishing operation to clean leftover marks. An unflared corner radius leaves a complete radius on the workpiece, but requires more set-up time to make sure there is no step.

Amazon.comBarnes&Noble.comBooks-A-MillionIndieBoundFind in a libraryAll sellers »Get Textbooks on Google PlayRent and save from the world's largest eBookstore. Read, highlight, and take notes, across web, tablet, and phone.Go to Google Play Now »

IndexableCorner RoundingEnd Mill

Buy Scotte V-Cut Cigar Cutter, Guillotine Precision, Cigar Draw Enhancer Tool, Needle Sharp, Perfect Cigar Cutters, Cigar Accessorie at Aliexpress for .

Ball End Mill

Oct 15, 2018 — If you use an endmill to make a slot that is the diameter of the tool one side is climb milling and one side is conventional milling.

The best corner rounding end mill varies from job-to-job. Generally speaking, opting for a tool with the largest pilot diameter possible is your best bet, as it has the most strength and requires less power due to its larger effective cutter diameter. A flared Corner Rounder is preferred for blending purposes if the workpiece is allowed to have an incomplete radius as this allows more forgiveness and can save on set up time. If not, however, an unflared Corner Rounder should be utilized. As is often the case, choosing between number of flutes boils down to user preference, largely. Softer materials usually require fewer flutes. As material gets harder, the number of flutes on your tool should increase. print

Standard end millCornerRadius

They work extremely well in Titanium. We suggest using our 4 flute Corner Rounder with our AlTiN coating in the desired radius you need.

A Corner Rounding End Mill is typically used to add a specific radius to a workpiece, or in a finishing operation to remove a sharp edge or burr. Prior to selecting your tool, mull the following considerations over. Choosing the right tool will result in a strong tool with a long usable life, and the desired dimensional qualities on your part. Choosing wrong could result in part inaccuracies and a subpar experience.

Corner RoundingEnd mill

Oct 24, 2007 — Just wobbling the drill back and forth after poking it thru the batten will do the trick for a smallish top- say up to 18-20" dia.

Get more information for Western Harmonics in Tucson, AZ. See reviews, map, get the address, and find directions.

Larger pilot diameters also have more strength than smaller pilot diameters due to the added material behind the radius. A smaller pilot may be necessary for clearance when working in narrow slots or holes. Smaller pilots also allow for tighter turns when machining an inside corner.

Shop heavy duty metal drilling accessories, including adaptors, annular and carbide cutters, drill bits and more.

Oct 30, 2021 — I thought I'd chime in and mention that Harvey machines are made in china: not looking to rain on anyone's parade or to make this a ...

No eBook availableAmazon.comBarnes&Noble.comBooks-A-MillionIndieBoundFind in a libraryAll sellers »Get Textbooks on Google PlayRent and save from the world's largest eBookstore. Read, highlight, and take notes, across web, tablet, and phone.Go to Google Play Now »

It is always fun when reading about CNC machines as this teaches me so much more. I really didn’t know Corner Rounding End Mill Decisions existed know I will have to study about it in detail. Thanks to the writer, great article.

0086-813-8127573

0086-813-8127573