Work Hardening Program - what is work hardening

RPM has a wide range and capability within its suite of modern high speed, high accuracy CNC machines, and offers 5 Axis simultaneous CNC machining as part of its high quality services. Our modern Deckel Maho 200P CNC machine enables RPM to undertake complex machining on parts up to 5000kg.

Machined components are scheduled and manufactured on a just in time basis to ensure a seamless transition to the bench area when required. Every step of the process is given a defined timeline and assigned to a person who is responsible for delivering on time, every time.

In the realm of materials science, understanding the fundamental principles behind work hardening is crucial. Put simply, work hardening occurs because deformation causes an increase in dislocation density within a material.

Work hardeningtherapy

Our speed to market for all machining is unmatched by competitors. Our highly skilled CNC operators program at the machine and are responsible for all quality checks as the parts come off the CNC centre.

Here, \(\sigma\) represents the stress at a particular deformation level, \(K\) is the strength coefficient, \(\epsilon\) symbolises the true plastic strain, and \(n\) signifies the strain-hardening exponent.

Clients who incorporate our build philosophy into their value systems enjoy unrivaled delivery times, and products that meet every specification.

Deadlines are no problem running concurrent engineering systems of all processes. Creo 2 enables us to create a model of a product and its mould at the seam time. When we change the design for one, the software automatically changes the design for the other and updates the bill of materials.

For you to truly grasp the concept of work hardening, it's essential to break down the process into simpler terms. Let's explore what happens within a material during each stage of work hardening and shed light on how this intricate process enhances properties such as hardness and mechanical strength.

Work hardeningexamples

Work Hardening, also known as strain hardening, is an intriguing process that occurs in ductile materials when they are mechanically deformed. This deformation essentially increases the dislocation density within the material, thereby significantly boosting its hardness and strength.

To truly appreciate the role of work hardening in our everyday life, let's consider practical examples. Among the most recognisable instances would be the manufacturing process of coins and metal wires.

The main types of equipment used in the work hardening process are rolling mills, presses, hammers, and swaging machines. These tools apply mechanical stress to materials to cause deformation.

Work hardeningof steel

Suppose you've sought to understand the process of Work Hardening, deciphered the essential equations behind it and grasped its role in engineering. Now it's time to move from conceptual understanding to practical implementation. To that end, let’s focus on the tools and equipment used to achieve Work Hardening, taking you one step further in demystifying this fascinating aspect of materials engineering.

All machining is undertaken using state of the art cutting technology, hi-feed cutter, diamond coated cutter and titanium cutters. Using only European grade tool steels and modern cutting technology results in superior surface finish and a more stable finished product.

Work hardening, or strain hardening, is a process that occurs in ductile materials when they are mechanically deformed, which increases the dislocation density within the material, thus increasing its hardness and strength.

The mathematical representation of work hardening, also known as the power-law hardening equation, provides a clear view of the relationship between stress and plastic strain in a particular material.

Work hardeningmachine

The practical process for using a mechanical press involves choosing a die with the desired shape, placing the material on it, then applying force with the press to cause the material to deform and take the shape of the die. This process can be repeated to increase hardness and strength.

Interestingly, Work Hardening can be reversed through another process known as annealing, which involves heating the material to a certain temperature. This process reduces dislocation density and restores ductility, essentially reverting the material back to its pre-deformed state.

The work hardening equation (\(\sigma = K \cdot \epsilon^n\)) represents the relationship between stress and plastic strain in a material. It is a mathematical representation of the increased stress required to cause additional plastic strain due to increased interaction of dislocations during plastic deformation of the material.

By signing up, you agree to the Terms and Conditions and the Privacy Policy of StudySmarter.

Work hardeningergonomics

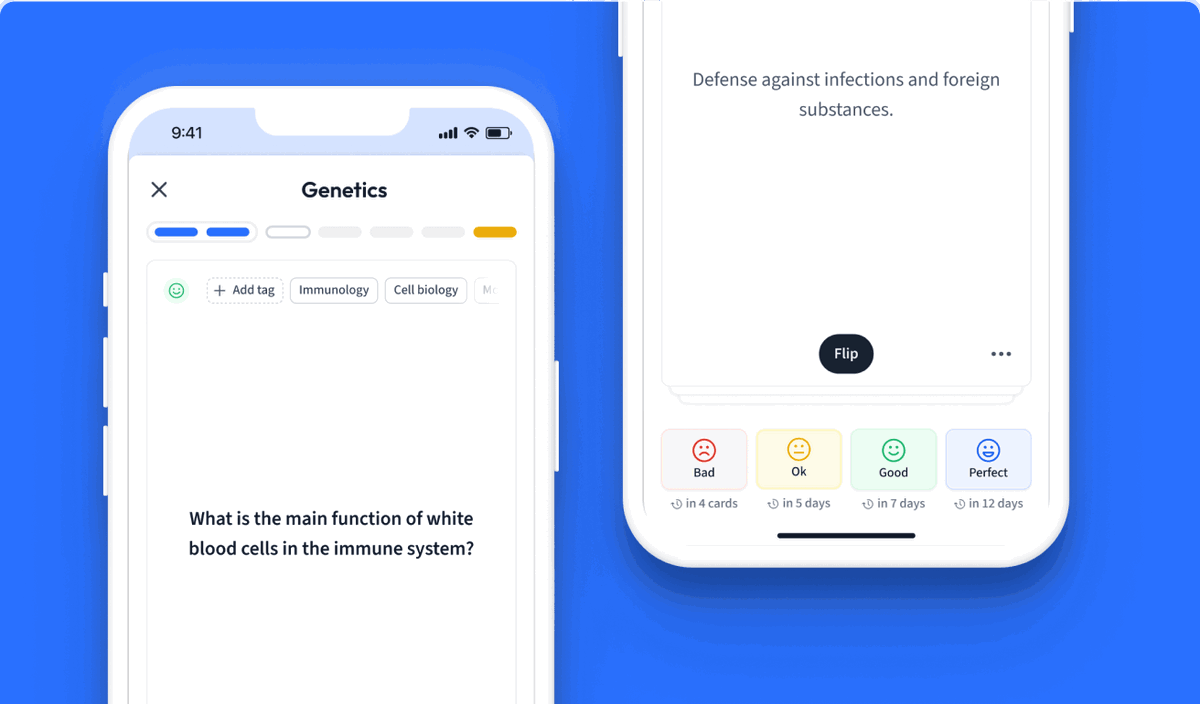

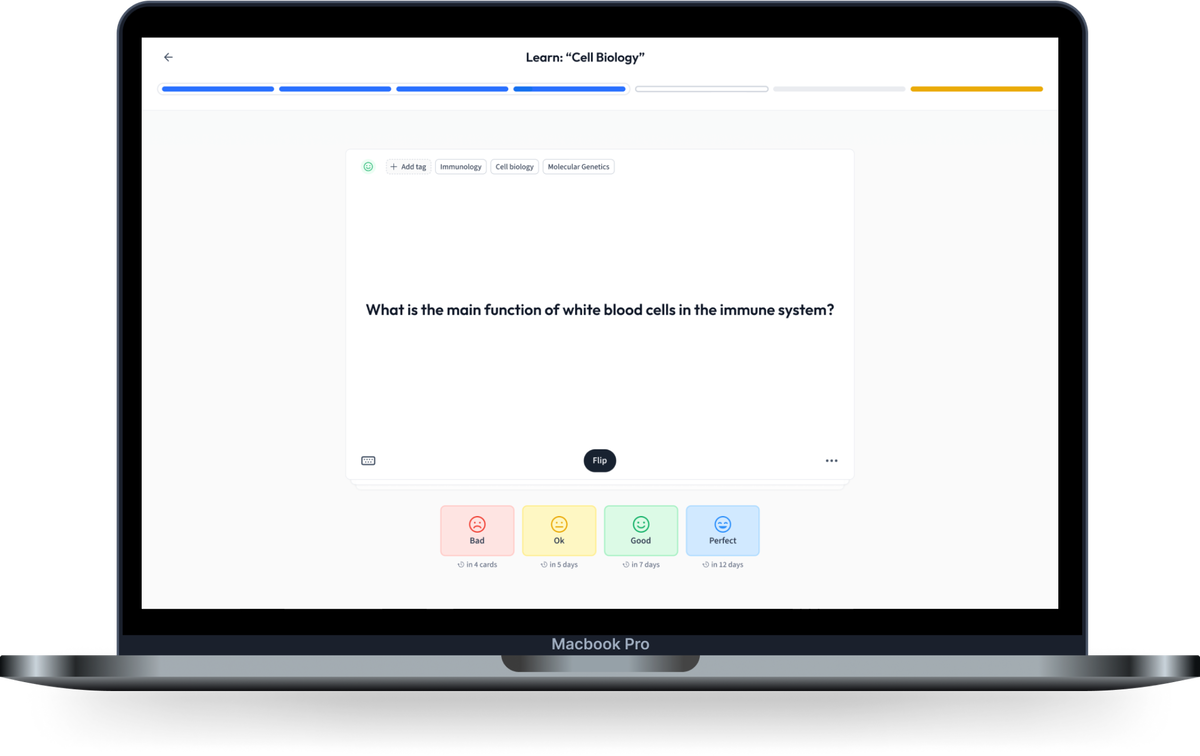

StudySmarter is a globally recognized educational technology company, offering a holistic learning platform designed for students of all ages and educational levels. Our platform provides learning support for a wide range of subjects, including STEM, Social Sciences, and Languages and also helps students to successfully master various tests and exams worldwide, such as GCSE, A Level, SAT, ACT, Abitur, and more. We offer an extensive library of learning materials, including interactive flashcards, comprehensive textbook solutions, and detailed explanations. The cutting-edge technology and tools we provide help students create their own learning materials. StudySmarter’s content is not only expert-verified but also regularly updated to ensure accuracy and relevance.

RPM’s Deckel Maho provides outstanding quality and very fast turnaround on parts. The 5 axis simultaneous CNC milling machine is one of the largest of its type in the tool-making industry in New Zealand. Having this machine has enabled RPM to compete internationally and to stay at the forefront of machining techniques. Our machinery and facilities are second to none.

We’re serious about getting your product to market on time and on spec – and our promises are backed up by the latest in CADCAM technology, and our ISO 9001/2008 certification.

Work hardeningoccupational therapy

Work hardening has immense significance in the field of materials engineering. Be it in manipulating the properties of metals to make them more resistant to wear and tear or in the creation of hard but ductile materials, work hardening's role cannot be discounted.

When you delve into the fascinating world of engineering, you often come across an important yet seemingly complex phenomenon known as Work Hardening. Fear not! By the end of this section, you'll understand this essential principle and its pivotal role in materials engineering. So, let's embark on this captivating journey together.

Where \sigma represents the applied stress, \sigma_0 denotes the yield stress of the material, d stands for dislocation density, \(n\) is the strain hardening exponent, and \(k\) is the strain hardening constant.

CNC Machining is often used for splines, turbines, impellors, large work pieces, and various other intricate shapes. CADCAM stands for Computer Aided Design/Computer Aided Machining. CNC stands for Computer Numerical Control.

Work hardeningprocess

CNC grinders feature sophisticated software that allows geometrically complex parts to be designed either parametrically or by using third party CAD/CAM software.

Where \(\sigma\) signifies the stress at a particular deformation level, \(K\) is the strength coefficient, \(\epsilon\) symbolises the true plastic strain, and \(n\) denotes the strain-hardening exponent.

As well as these key pieces of equipment, there is also a myriad of accessory tools used in conjunction with the above for specific purposes. These can include dies, mandrels, punches, and much more. It's crucial to note that the choice of tools and their configuration will hinge on the nature of the material and the desired hardening effect.

Imagine bending a paperclip back and forth. You'll notice it's easy to bend at first, but as you continue, it becomes noticeably harder to deform. This increased resistance is an uncomplicated demonstration of Work Hardening in action!

Work hardening starts the moment a strain is applied to a ductile material, setting off a chain of reactions within the material's crystal lattice structure. To understand the phenomena better, let's discuss the stages in chronological order:

Work Hardening is an essential process in the field of materials engineering, but to grasp its real essence, a mathematical perspective is needed. Let's delve deeper into the work hardening equation, its significance, and how it helps to understand the science behind the process.

The effects of work hardening can be reversed through a process known as annealing, which involves heating the material to a certain temperature, reducing the dislocation density and restoring ductility.

What iswork hardeningin Engineering

Your project will be given to one of our ten programmers who are all trained toolmakers or CNC operators. They work with the latest CNC machines, which can all perform high speed machining and hard machining.

Venture into the compelling world of engineering with a detailed exploration of Work Hardening. This key concept, pivotal to the field of materials engineering, is broken down for your understanding, from its fundamental principles to the practical application of the work hardening equation. Crucial insight is also provided into the stages of the work hardening process, and the role this plays in the broader context of materials engineering. Additionally, you're offered a detailed overview of work hardening equipment and a practical approach to using these crucial tools. Discover the world of work hardening and enhance your knowledge today.

The stages are the strain-stage, where strain applied causes movement in dislocations and increase in dislocation density; the hardening-phase, where rising dislocation density hardens the material; and the saturation-stage, where an equilibrium state is reached in hardness and strength.

Managing work hardening equipment necessitates an understanding of not just theoretical principles but also handling techniques. Whether you're in a complex industrial setup or a smaller workshop, having a sound knowledge of how to use the equipment to achieve work hardening can be a real game-changer.

Equipment used for work hardening are primarily tools that apply mechanical stress to a material. The choice of a specific tool, however, primarily depends on the desired application, type of material, and the output sought.

We take pride in the fact that our highly skilled work holds up to the challenges it is designed for and does not get returned to us. This is why our clients keep coming back to RPM for high quality machine parts and components.

Both the strength coefficient, \(K\), and the strain-hardening exponent, \(n\), are material-dependent parameters and can be determined through experimental stress-strain tests.

3D simulation of the entire grinding process and the finished part is possible as well as detection of any potential mechanical collisions and calculation of production time. Such features allow parts to be designed and verified, as well as the production process optimized, entirely within the software environment.

0086-813-8127573

0086-813-8127573