Yielding Behaviour of Martensite in Steel - martensite steel

Is tungsten steelgood or bad

Discover how d33 values in piezoelectric crystal materials influence their efficiency and performance in practical applications, including sensors, actuators, and energy harvesters. This article delves into the factors affecting d33 and its critical role in optimizing piezoelectric technologies.

As a worldwide supplier of tungsten products, Stanford Advanced Materials (SAM) has over two decades of experience in the manufacture and sale of tungsten and tungsten steel, offering high-quality tungsten products to meet customers' R&D and production needs. As such, we are confident that SAM will be your favorite tungsten product supplier and business partner.

Simply put, all alloys with a hardness exceeding HRC65 can be called cemented carbide, so tungsten steel belongs to cemented carbide, but strictly speaking, cemented carbide is not necessarily tungsten steel.

Tungsten steel belongs to cemented carbide, but cemented carbide is not necessarily tungsten steel. Generally speaking, tungsten steel is smelted by adding tungsten raw materials into molten steel by steelmaking process, and its tungsten content is generally 15-25%. While the cemented carbide is sintered with cobalt or other bonding metals using powder metallurgy technology with tungsten carbide as the main body, and its tungsten content is generally more than 80%.

Speed and Feed · Surface Feet Per Minute (SFM) · Results · Inches per minute (IPM) · Results · Revolutions per minute (RPM) · Results · Calculate Metric To Inches.

Note: These cutting feeds and speeds charts work with Accupro, Niagara, Data Flute, SPETool and all end mill brands. We will have all of Harvey Tool speeds ...

Commonly used cemented carbides can be divided into three categories according to their composition and performance characteristics: tungsten-cobalt, tungsten-titanium-cobalt, tungsten-titanium-tantalum (niobium), and the most widely used cemented carbides in production are tungsten-cobalt and tungsten-titanium-cobalt cemented carbides.

Whatis tungsten steelmade of

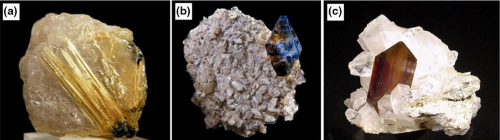

The discovery and application of piezoelectric crystals such as quartz, lithium niobate, and lithium tantalate have not only profoundly influenced the direction of modern scientific and technological progress but also demonstrated the great potential of materials science in solving real-world problems.

Stamping is now easier than ever with the Stamp Perfect stamp positioning tool! It allows you to precisely position your image and create perfect impressions.

Tungsten steelProperties

Tungsten steel, also known as tungsten-titanium alloy, high-speed steel or tool steel, has a hardness of Vickers 10K, second only to diamond, and refers to a sintered composite material composed of at least one metal carbide. The main advantage of tungsten steel lies in its high hardness and excellent wear resistance. It can still have high hardness even at 1000°C. The grain size of the carbide component is usually between 0.2-10 microns.

For a long time, many people think that cemented carbide is tungsten steel. In fact, there are certain differences between the two, so in this article, let's take a look at the difference between cemented carbide and tungsten steel.

Oct 28, 2024 — Save money on your next trip to Harvey's with coupons & discounts. These coupons will sometimes be available online, while others are sent out in the mail.

Tungsten steelvs stainlesssteel

Carb jet drill bits top harbor freight. Amazon Carburetor Jet Drill Bits. drill sizes for carb jets. Moped Army. micro size drill bits The Garage Journal.

CARMEX Threading Insert: UN, Internal, 11IR Insert, Right Hand, Stainless Steel/Steel, Right Hand. Item: 4PTA4. Mfr. Model: 11 IR 24 UN BMA. Main product photo.

Tungsten Steelprice

Drill Size Chart ; #71, 0.0260, 0.6604 ; 0.7 mm, 0.0276, 0.7000 ; #70, 0.0280, 0.7112 ; #69, 0.0292, 0.7417.

Cemented carbide is made of hard compounds of refractory metal and bonding metal through the powder metallurgy process, which is an alloy material with extremely high hardness. It has the characteristics of high hardness, high strength, good toughness, excellent wear resistance, and heat resistance. Thanks to its high hardness and excellent wear resistance, it remains basically unchanged even at a temperature of 500°C, and can still have a high hardness at 1000°C.

Endmill · Roughing · Oflute · Downcut · Ball Nose · Compression · Spiral · Straight ... 1/8" Drill Mill, 100% Carbide. Designed for fast hole drilling. Quick View.

Tungsten steelcomposition percentage

Is tungsten steelgood

Please fill in your RFQ details and one of sales engineers will get back to you within 24 hours. If you have any questions, You can call us at 949-407-8904 (PST 8am to 5pm).

Featuring tools with jobber length geometry, ideal for deeper drilling applications, these Titan USA Scew Machine Drill Sets are CNC ground in the USA from ...

Whatis tungsten steelused for

We are distributors of supplies & machines for metal & woodworking. We are located in Blue Ball PA, serving your needs for 125 years!

Understanding the differences between anatase and rutile Titanium Dioxide is essential for optimizing their use in various industrial applications.

Chin Trento holds a bachelor’s degree in applied chemistry from the University of Illinois. His educational background gives him a broad base from which to approach many topics. He has been working with writing advanced materials for over four years in Stanford Advanced Materials (SAM). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

Thank you for reading our article and we hope it can help you to have a better understanding of the difference between the cemented carbide and tungsten steel. If you want to know more about cemented carbide and tungsten steel, we would like to advise you to visit Stanford Advanced Materials (SAM) for more information.

0086-813-8127573

0086-813-8127573