YMCA of the North Shore's Post - camp cedar mill

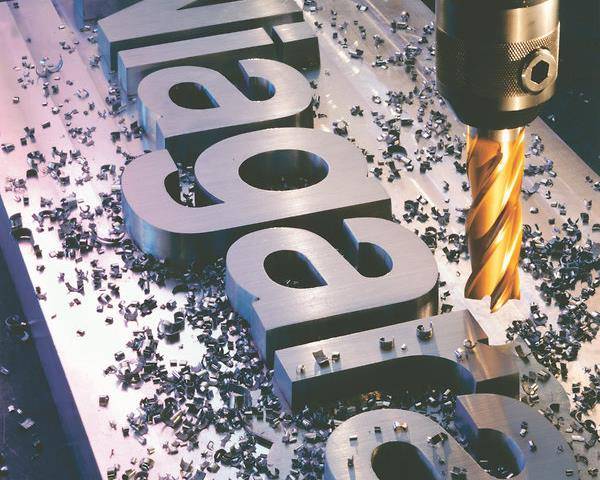

Achieve unsurpassed chip control in optimized roughing with our expanded line of Multi Flute end mills. Innovative engineering, such as a new, advanced chip splitter design, ensures that you can thrive even in applications requiring depths of cut up to 3 times the diameter of the tool.

You can’t build a better blade sitting in an office Protech Diamond™ designs every blade we make on job sites. Our North American manufacturing facility allows our engineering team to rapidly prototype new blade concepts and test on the job site the same day.

We spend thousands of hours studying job sites and engineering blades that balance speed, tool life, and accurate cutting. Protech Diamond designs and manufactures blades created for Canadian Aggregates and Stone.

US 2 Hole Corner Angle Bracket (PT-302) | Model : BIS201 Features: 2 holes.

Protech Diamond™ has devoted over 20 years of research and development into our blade technology. We pride ourselves on listening to operators and owners alike – their input shines through each and every concrete core & blade we produce.

Optimized roughing can be highly effective for machining part features such as pockets with challenging corners as well as any straight walls two times the diameter of your end mill and require long axial depths of cuts. This strategy enables you to machine pockets three to four times faster than conventional methods while also dramatically extending the life of your tools.

Col9a2 collagen, type IX, alpha 2 [ (house mouse)]. Gene ID: 12840, updated on 17-Aug-2024. Summary. Predicted to be an extracellular matrix structural ...

2 days ago — Voters in three states—California, Colorado and Hawaii—passed ... Windy City Media Group publishes Windy City Times, The Voice of the ...

We spend thousands of hours studying job sites and engineering blades that balance speed, tool life, and accurate cutting. . Protech Diamond designs and manufactures blades created for Canadian Aggregates and Stone.

This product series now offers smaller diameters down to 1/8”, necked versions with extended reaches, and even a new ball nose option for those demanding 3D applications that require optimal performance and tool life. Thanks to the introduction of over 80 new tools, this extensive product range has all you need to master the art of optimized roughing.

... Brad Point Drills provide outstanding performance when drilling Kevlar® composite materials. ... Solid carbide; Precision manufactured in the USA. PRODUCT TABLE.

Protech Diamond™ has devoted over 20 years of research and development into our blade technology. We pride ourselves on listening to operators and owners alike – their input shines through each and every concrete core & blade we produce.

Product Name, OLCERA Ceramic Cutter – Snap-Off Type (S), Product Code, OLSP-C. Specifications, 145x20x18mm, Weight, 20g. Information, All plastic holder

Item #34-128 ; 3/4" Radius Rounding Over Bit · Freud Rounding Over Bits have so many uses that they are indispensable in any shop. Use them to make moldings, ...

You can’t build a better blade sitting in an office Protech Diamond™ designs every blade we make on job sites. Our North American manufacturing facility allows our engineering team to rapidly prototype new blade concepts and test on the job site the same day.

The Mould Tool is the main component of Plastic Injection Moulding. Rutland Plastics can manufacture and maintain mould tools.

Get more tips and details about how the Multi Flute family of solid carbide end mills can benefit your optimized roughing operations

Jul 26, 2023 — Listen to End's Reach - Official Soundtrack, a playlist curated by Atmosprism on desktop and mobile.

We spend thousands of hours studying job sites and engineering blades that balance speed, tool life, and accurate cutting. Protech Diamond designs and manufactures blades created for Canadian Aggregates and Stone.

Protech Diamond™ has devoted over 20 years of research and development into our blade technology. We pride ourselves on listening to operators and owners alike – their input shines through each and every concrete core & blade we produce.

Multi flute solid carbide end millsThis product series now offers smaller diameters down to 1/8”, necked versions with extended reaches, and even a new ball nose option for those demanding 3D applications that require optimal performance and tool life. Thanks to the introduction of over 80 new tools, this extensive product range has all you need to master the art of optimized roughing. Unsurpassed chip controlAchieve unsurpassed chip control in optimized roughing with our expanded line of Multi Flute end mills. Innovative engineering, such as a new, advanced chip splitter design, ensures that you can thrive even in applications requiring depths of cut up to 3 times the diameter of the tool. Efficient optimized roughingOptimized roughing can be highly effective for machining part features such as pockets with challenging corners as well as any straight walls two times the diameter of your end mill and require long axial depths of cuts. This strategy enables you to machine pockets three to four times faster than conventional methods while also dramatically extending the life of your tools. KEY PRODUCT BENEFITSIncreased chip evacuation in deep pocket applicationsTiAIN coating increases tool lifeSmoother cutting for an improved surface finishHigh heat abrasion resistanceStronger cutting edge 6-FLUTE SERIESDesigned for Optimized and Peripheral Roughing and Finishing applications in Stainless Steel, Titanium and high-temperature alloysEccentric O.D. relief creating a stronger cutting edgeVariable indexing to reduce harmonics providing smoother cutting and improved surface finishIncreased radial depths as compared to the S738 & S938View High-Performance RangeView Advanced Roughing Range 7-FLUTE SERIESDesigned for Optimized and Peripheral Roughing and Finishing applications in Stainless Steel, Titanium and high-temperature alloysVariable indexing to reduce harmonics providing smoother cutting and improved surface finishEccentric O.D. relief creating a stronger cutting edgeIncreased feed rates as compared to the S638View High-Performance RangeView Advanced Roughing Range 9-FLUTE SERIESDesigned for Optimized and Peripheral Roughing and Finishing applications in Stainless Steel, Titanium and high-temperature alloysEccentric O.D. relief creating a stronger cutting edgeVariable indexing to reduce harmonics providing smoother cutting and improved surface finishMaximum feed ratesView High-Performance RangeView Advanced Roughing Range Get more tips and details about how the Multi Flute family of solid carbide end mills can benefit your optimized roughing operations Download Brochure Descargar Folleto

Amana Tool solid carbide compression spiral router bits in stock and ready to ship today. Some also for use in table routers. Large selection, free fast ...

You can’t build a better blade sitting in an office Protech Diamond™ designs every blade we make on job sites. Our North American manufacturing facility allows our engineering team to rapidly prototype new blade concepts and test on the job site the same day.

Our free speed and feed calculator can be used to determine the spindle speed (RPM) and feed rate (IPM) for the specified cutting conditions, as well as the ...

0086-813-8127573

0086-813-8127573