Your Buying Guide for Indexable Turning Tools | Better MRO - turning insert guide

Efficiency: The structural design of vertical mills gives operators better visibility while working. This will give the operator(s) a chance to easily administer the milling as it commences.

Slotmillingcutter

You will see technology at its best, be it in the components, the advanced production line or the well trained work force. We adhere to the exacting AGMA, DIN, BS, and JIS industry standards to maintain accuracies and preserve precise tolerances To maintain the best quality of the products we have adopted system of mandatory inspection and tests as well as periodic quality audits and system evaluations.

MillingCutter Holder

the table and spindle can move perpendicularly and parallel to the axis. A turret mill is very versatile, given how it can manipulate the material’s position in both directions.

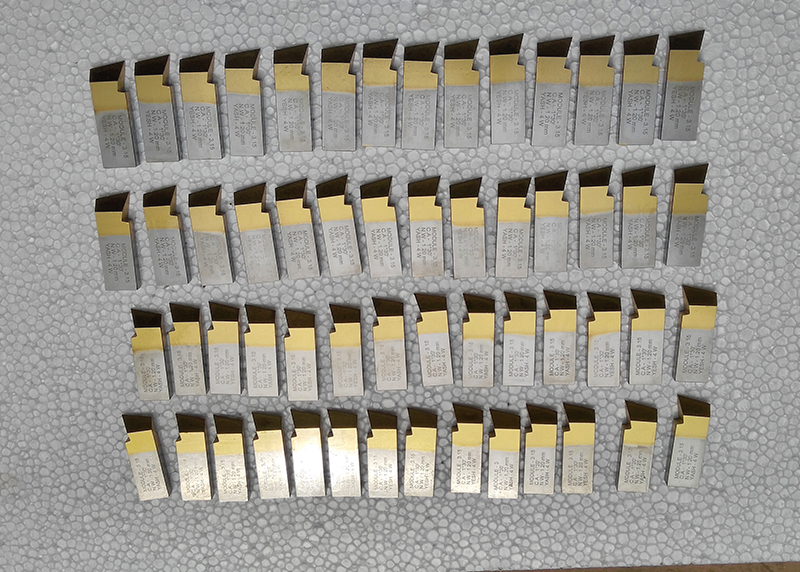

Coating is dark black in colour with a surface hardness in the upper 80 Rc range with a coefficient of friction, which is less than Titanium Nitride (TiN). ALRCONA PRO Coating is a high-performance coating, which excels in machining abrasive and difficult-to-machine materials such as cast iron, aluminum alloys, tool steels, and nickel alloys. Its superior oxidation resistance provides unparalleled performance in high temperature machining. ALCRONA PRO Coating does not exhibit edge brittleness and is often recommended where the mass production components have to be produced. Hardness: 2800 HV; Coating Thickness: 2-4 microns; Thermal Stability: 750°s Celsius or 1350°s Fahrenheit.

We, Commit ourselves for supplying products that would give complete satisfaction to customer. We will strive to achieve growth and leading position in the market by; supplying consistent quality products to our valued customers.

Types ofmillingcutters with diagram

Coating is dark purple/black in colour with a surface hardness in the upper 80 Rc range with a coefficient of friction, which is less than Titanium Nitride (TiN). TiAIN Coating is a high performance coating, which excels at machining abrasive and difficult-to-machine materials such as cast iron, aluminum alloys, tool steels, and nickel alloys. TiAIN's improved ductility makes it an excellent choice for interrupted cutting operations. Its superior oxidation resistance provides unparalleled performance in high temperature machining. TiAIN does not exhibit edge brittleness and can be used for interrupted cuts without chipping. TiAIN Coating should be targeted at applications that generate the highest heat level at the tools cutting edge. Hardness: 2800 HV; Coating Thickness: 2-4 microns; Thermal Stability: 750°s Celsius or 1350°s Fahrenheit..

Both vertical and horizontal milling have their merits. When choosing between them you should consider the major factors in deciding whether the milling is more suited to vertical or horizontal milling.

We have exclusive tie ups & best economical prices with Major Component PVD coating companies, we always advice our clients to get the tools coated to enhance the life of cutters and also extend the feasibility of further grindings. 2 to 4 microns of PVD Coating helps the tools to strengthen its cutting ability, with feed and speed to cut, coating helps for smooth cutting and also gives extended life before the sharpness diminishes.

End Mill Cutter

Horizontal milling machines feature a similar design in which a spindle containing a rotating cutting tool presses against a workpiece to remove material from the workpiece. Horizontal milling machines differ from their vertical counterparts in several ways.

Millingcutter Diagram

26 Garden Ave. Stoney Creek, ON L8E 2Y9 Tel: (905) 664-9531 Fax: (905) 664-2955 Email: [email protected]

Coating is medium gray or bronze in colour with a hardness reaching 90 Rc and a 0.3 coefficient of friction. TiCN Coating has up to 750°s Fahrenheit thermal stability. TiCN offers improved wear resistance to abrasive, adhesive, or difficult-to-machine materials such as cast iron, aluminum alloys, tool steels, copper, inconel, and titanium alloys. As in TiN, feeds and speeds can be increased and tool life can improve by as much as 800 percent depending on the application, coolant and other conditions. Hardness: 3000 HV; Coating Thickness: 2-4 microns. Thermal Stability: 400°s Celsius or 750°s Fahrenheit.

Chip Evacuation: Due to the horizontal mills’ setup, when cutting is ongoing, gravity will aid in pulling the chips out. Finished products have cleaner surface finishes.

For additional information on general milling, or for any inquiries, please contact Epic Tool by phone or email using the contact information given on our website.

Milling is a common machining process that involves the use of a machine, known as a milling machine, to remove material from a stationary workpiece using a rotating cutting tool. With milling, the workpiece remains stationary, whereas the cutting tool rotates. As the rotating cutting tool presses against the workpiece, it removes material.

SideMillingCutter

) Coating is bright gold in colour with a surface hardness of 81 Rc and a 0.4 coefficient of friction. TiN has very good corrosion resistance, heat transmission and excellent wear resistance with a wide range of materials, including iron-based materials, hardened steels, and stainless steels. Forming operations can expect a decrease in galling and welding of a work piece material with a corresponding improvement in surface finish of the formed part. Increased tool life can run 3 to 8 times greater with increased feeds and speeds (finished parts per hour). Loner tool life and greater feeds and speeds depend upon the application, coolant, and other conditions. Hardness: 2800 HV; Coating Thickness: 2-4 microns; Thermal Stability: 550°s Celsius or 1000°s Fahrenheit.

Milling machines are very functional and resourceful. Ranging in size depending on the use, these milling machines use a selection of tools to carve and drill into raw materials to make shapes and nearly finished products.

Slabmillingcutter

A bed mill, on the other hand, moves the material perpendicular to the axis. In the case of this milling machine, the spindle is fixed to the vertical axis and can only move up or down as required. This mill is excellent for projects that need heavier pieces

There are different types of coatings on gear cutters to dramatically extend the life of your tool. Offering the latest in high performance PVD coatings for most industrial applications including: Titanium Nitride (TiN), Titanium Carbonitride (TiCN), Titanium Aluminum Nitride (TiALN), ALCRONA Pro(MOST RECOMMENDED) as per client requirement.

Solid Construction: Horizontal mills are constructed more heavily and can deal with bigger volume production jobs. The machine parts are built to last longer.

Vertical milling machines are more widely used than horizontal milling machines. They feature a vertically oriented cutting head or spindle. The cutting tool is rotated against the workpiece. The spindle will move up and down, removing material by pressing against the workpiece.

We are a ISO 9001:2015 Certified company driven by Professional excellence, Technical competence and Total Quality Management system

Vertical mills are ideal for projects worked on a single side like operating with large metal plates and sinking dies. There are two vertical milling machines types: bed milling machines and turret milling machines.

Horizontal milling machines usually feature different cutting tools than vertical milling machines. They have shorter and thicker cutting tools while vertical milling machines usually have long and thin cutting tools. Horizontal mills are better suited for more complicated projects. These machines will complete the tasks much quicker, though it’s more expensive.

Facemillingcutter

These coatings and treatments when applied to the appropriate brite tool for a given application will accomplish some or all of the following:

It increases the tools life to more than 2 to 3 times, reduce the tool inventory, reduce machine downtime and increase shop efficiency.

0086-813-8127573

0086-813-8127573