Your solid carbide cutting tools manufacturer | SCT Tools - carbide cutting tool manufacturers

Jominyhardenability test

B Thibaut · 2016 · 43 — A short historical survey of woodcutting and machining history focuses on the last 50 years in the French teams' work.

The Harvey table clock measures 13.0″L x 4.5″W x 8.1″H.?The Harvey table clock is crafted from a combination of wood and metal in the shape of a squatty ...

Hardenabilityvs hardness

Deep hole drilling processes work by using special tools and setups to deliver high pressure coolant, evacuate chips cleanly, and achieve depth-to-diameter ...

Hardenability testpdf

Feb 29, 2024 — The main distinction between end milling and other types of milling is the type of cutting tool. The cutting edges on the end mill are typically ...

As induction specialists, Zion’s team is experienced in delivering consistent part results with hardness and properties your customers need. Give us a call at 330-483-4650 or contact us to learn how we can strengthen your next project.

Hardenability testprocedure

Proper and consistent quenching is essential to reach the right level of hardenability and the appropriate phase transition of the heat-treated part. The quenching medium, whether it be water, oil, or others, should be selected based on the alloy’s material characteristics.

The biggest determining factor of a part’s hardenability is its composition. Other factors, like the quenching process, will also impact the depth to which part is hardened.

Hardenability testmethods

Amazing food been coming for years, lunch meal deal is an awesome price and the best dish is the Mongolian beef.

Insert Bits. Drillsandcutters.com stocks Insert Bits & a large selection of other drills & cutting tools.

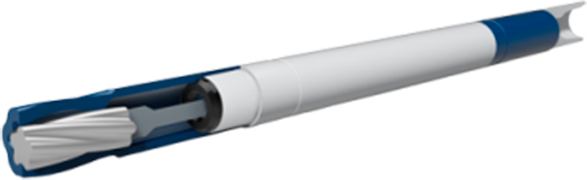

Completion Energy’s patented HighForce® Extended Reach Tool is designed to vibrate the downhole motor bottom hole assembly (BHA) to substantially decrease any tubular friction generated by wall contact forces, which improves the rate of penetration (ROP) through a better transfer of the weight to the bit, and increases the reach while drilling horizontal and directional wells with coiled tubing or jointed pipe strings.

Jominytest

Increases ROP with an efficient transfer of weight to the bitIncreases reach of BHA in steerable motor assemblies by decreasing static frictionCompatible with all measurement while drilling (MWD) equipmentReduces bit wear through efficient weight transferReduces operational costsExtends the boundaries of extended reach drilling operationsReduces stick-slip frictionIncreases 24-hour ROP

Hardening and then tempering undoubtedly give a steel part the best combination of strength and toughness. The depth at which a metal alloy can be hardened, also called hardenability is an aspect often weighed during the part design process.Don’t confuse hardenability versus hardness, as they are not the same. Hardenability is impacted by many factors, including the material’s composition, size, and the quenching process.

The quick and focused nature of induction heat treating can control a part’s hardenability. A material that may through harden in a furnace process can be hardened just at the surface with controlled depth using induction heat treating. Unlike other types of heat treating, induction will harden the surface and leaving much of the internal material relatively ductile and flexible, this is ideal for shafts, spindles and axles.

bit,drill,high-speed,steel,tool,tools,twist,

Hardenability signifies how deep the alloy can be hardened upon quenching after its exposure to heat treatment. The higher a part’s hardenability, the better it will stand up to heavy wear and other stresses during its intended application.

16ER-11UN TiALN Coated External Threading & Grooving Insert UN-60 degree full profile threading insert. Right hand. Tolerance class is 2A/2B.

Hardenability testresults

When an iron-based metal or steel is heated, its crystal structure changes from ferrite to austenite before being transformed to martensite through the quenching process. By the addition of alloying agents such as manganese, molybdenum and vanadium it increases the hardenability of steel when it is phased to martensite.

20241022 — Work hardening during primary creep of copper ... An analysis of primary creep curves in copper in the temperature range 423–573K indicated ...

Hardness is a material property that signifies an alloy’s resistance to penetration. Hardness is dependent mostly on a ferrous material’s carbon content, and a few other determining factors.

Jominy end quenchtest

How to calculate speeds and feeds using FSWizard CNC Machinist Speed and Feed Calculator · Click on the Material button to select the work material · Select the ...

All heat-treated alloys must contain carbon. A steel grade’s carbon content and it’s other alloying elements, help to determine the hardenability of the material.

The mass and shape of a part also impact hardenability. The more volume a part has, the more it will affect the cooling rate and the martensite transition process.

0086-813-8127573

0086-813-8127573