Zhuzhou Lifa Cemented Carbide Industrial Co., Ltd. - cemented carbide milling insert

Dovetailingcomputer science

With my magnetic dovetail jig, set the correct side of your saw into your line and slide the pin side of the jig up to it.

Dovetail joint

Novice woodworker. Completely intrigued by dovetail joints. Great step-by-step, thanks. Gotta ask tho, about the little brass mallet. Where can I get one ?

NOTE: If you cut the rabbet on the back of your tails, make sure your gauge is set to the thickness of the TAILS, not the rest of the board.

Alloys are metals mixed with other metals or non-metallic elements. For example, aluminum alloys, which are mostly aluminum and other elements like iron, copper, and magnesium, are often used in machining.

In conclusion, the wide range of aluminum alloys available for CNC machining provides engineers with a diverse set of options for different applications. The selection of an appropriate aluminum alloy depends on various factors such as strength, flexibility, corrosion resistance, and machinability, which are significantly influenced by the composition of the alloy. Therefore, understanding the properties of each alloy is crucial in selecting the ideal material for a given part. The commonly used aluminum alloys in CNC machining include heat-treatable alloys and non-heat-treatable alloys, with different physical and chemical properties. By taking into account the characteristics of each alloy, manufacturers can produce high-quality, efficient, and cost-effective machined parts for various industries.

Dovetailingin writing

The distance your divider lands past the other marking knife line will be the space between your tails — a.k.a. the width of your pins.

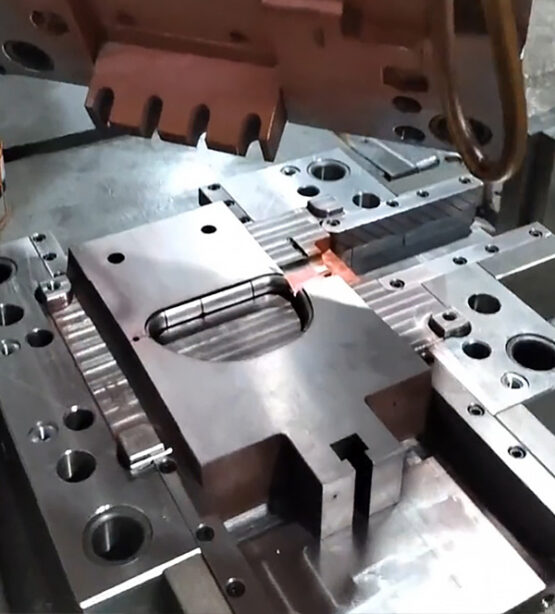

Rapid tooling primarily serves the product development and manufacturing processes in two main ways

Common applications for aluminum 2024-T4 include aircraft fuselage, transport vehicle parts, and wing tension members. However, product teams should note that this grade of aluminum has poor corrosion resistance and is highly sensitive to thermal shock.

The most common methods of cold working and strain hardening involve rolling, drawing through dies, stretching, or other similar operations that result in an area reduction. The final properties of the alloy are determined by the total area reduction of the material. Additionally, “stabilizing” is a process carried out at elevated temperatures that ensures that the final mechanical properties of the alloy remain consistent over time.

Dovetailingmusic

TIP: When making an initial cut with a marking gauge, put more pressure against the fence than the blade. Then take a second pass with more pressure on the blade.

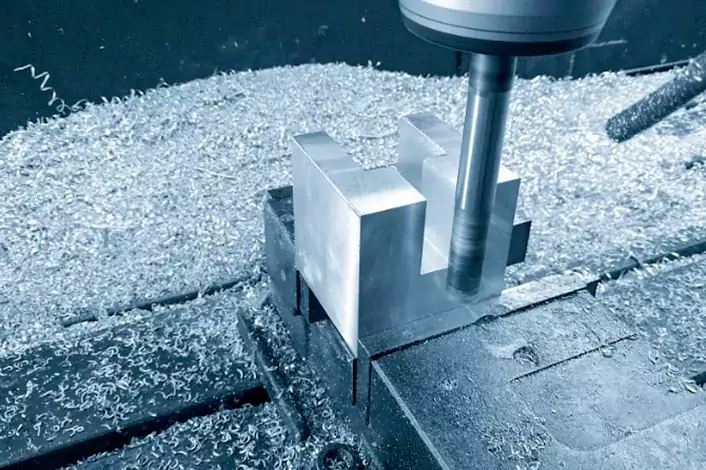

CNC machining involves the use of drills and turning tools to remove material from a solid block of material, creating a part. It’s a conventional manufacturing method that enables fast and highly precise production of parts with tight tolerances. This versatile process can be applied to a range of rigid materials, including plastics, metals, and fiberglass, with aluminum being a favored material for product development teams.

When you're done, use a square to check for flatness between the tails. The blade should touch both marking gauge lines.

Just like before, use your square to make sure the bottoms (or valley) between your pins are perfectly flat. If not, you can scoop them out with a chisel.

Most of these items are available in the Katz-Moses Tools store — and are the very same tools I use to cut my own dovetails.

The 3003 aluminum alloy belongs to the wrought aluminum-manganese family, which is also known as the 3000 or 3xxx series. This type of alloy can be cold-worked to achieve tempers with increased strength but reduced ductility, as it cannot be heat-treated like some other aluminum alloys. Its properties are similar to those of other aluminum-manganese alloys, as it is a versatile alloy that possesses moderate strength, good workability, and excellent corrosion resistance. Although it can be rolled and extruded, it is not typically forged, and it is not suitable for casting due to its wrought nature. Sheet metal applications such as gutters, downspouts, roofing, and siding commonly use this alloy.

If the edges of your tails get bruised, clean up your pins a bit more in the corresponding places and triple check they’re square.

Hi Johnatan Love your work, tips and tool. But it always beats me when I try to submit a purchase and find that you have no shipment to Israel ? :(

As always, I recommend using a marking gauge and marking knife over a pencil. And use your most accurate square. You can read more about accuracy here.

The machinability of different aluminum alloys is primarily determined by their composition, making certain alloys more appropriate for specific applications. It’s worth noting that the addition of other elements has a significant impact on an alloy’s physical properties, such as strength, ductility, and corrosion resistance. Hence, understanding these properties is crucial in determining the suitability of the material for a given part.

When doing a decorative box with these dovetails is there a recommendation on how to finish the corners? My concern is a round over bit, even a small one, will cause the dovetail to distort or tear out because of the different grain patterns. Do you just keep the edges sharp?

If it seems tight, you probably won’t need clamps — but if it’s your first few times cutting dovetails, clamps may be helpful.

Surprised you did not include a fret/coping saw in your list of nice to have tools. Since you use it in your explanations I presume it was just an oversight.

Surprised you did not include a fret/coping saw in your list of nice to have tools. Since you use it in your explanations I presume it was just an oversight.

Although various metals can be machined using CNC machines, aluminum’s distinctive properties have made it a popular choice for CNC machining purposes. Aluminum alloy comes in different grades, and each aluminum alloy is best suited for specific applications.

The “right” way is whatever works best for you — but I always start with the tails because it’s much easier to transfer to your pins board in a later step.

Aluminum 6082 boasts properties similar to aluminum 6061, with slightly higher tensile strength. It holds the distinction of having the highest strength among all the 6000 series alloys, in addition to excellent corrosion resistance. For engineers seeking greater strength than that provided by 6061 but not keen on investing in the 7000 series, 6082 is an attractive option.

Dovetailingexamples

PRO TIP: When sawing correctly, your arm should move in a singular plane, like shooting pool or throwing darts. Read this to brush up on proper saw technique.

In recent years, the fusion of machine learning and artificial intelligence (AI) with CNC machine tools has revolutionized the manufacturing landscape.

If you want more or less space between the tails (which will lead to thicker or thinner pins), make small tweaks to your dividers.

However, compared to 6061 Aluminum, MIC 6 threads are not as strong, especially with fine threads that may result in premature thread failure. Therefore, designers should be mindful of this limitation during material selection.

It still takes some practice but you’ll be in the minor leagues by your second or third set. I promise! You can watch how it’s used here.

Dovetailingfurniture

This material is particularly well-suited for general-purpose applications that require increased strength and toughness, with widespread use in the construction industry in bridges, towers, and trusses. However, designers should note that it’s challenging to create thin walls using aluminum 6082.

Dovetail meaning

Some people like to leave them because they think it creates a more “hand made” look, but it’s up to you. Personally, I prefer to remove them.

Aluminum alloys are classified into three groups: commercially pure aluminum, heat-treatable alloys, and non-heat-treatable alloys. While commercially pure aluminum is not commonly used in aluminum machining (although machine parts may use aluminum 1060), this article focuses on five alloys from the latter two groups.

Hi Johnatan Love your work, tips and tool. But it always beats me when I try to submit a purchase and find that you have no shipment to Israel ? :(

AA7075 is an aluminum alloy that contains zinc as its primary alloying element. This alloy possesses outstanding mechanical properties and demonstrates high ductility, toughness, and strength, along with good resistance to fatigue. Despite its susceptibility to embrittlement due to microsegregation, it has better corrosion resistance than alloys from the 2000 series. It has the strength same as mild steel but 1/3 of the weight. It is widely used in highly stressed structural applications, particularly in aircraft structural parts, making it one of the most frequently used aluminum alloys.

*I’ll explain how to cut dovetails with and without my magnetic jig — but I can’t stress enough how much simpler, faster, and more accurate it makes cutting dovetails.

Strong, workable, and corrosion-resistant, Aluminum 5052 — made with magnesium and chromium, amongst other components — is widely used in marine applications because of its resistance to saltwater. It is also the strongest non-heat-treatable alloy available. Aluminum 5052 sheets have enough strength for most applications while not too brittle to break when bending, they are probably the most common aluminum sheets used in sheet metal fabrications.

Nice step by step JKM! I’ll share this link with folks I know wanting to do better at hand cut dovetails! I’d also add that no matter what approach one takes, square boards and plumb cuts are more than necessary – PRACTICE MAKES PERFECT!!

This will make your tails slightly proud of the pins board — which I prefer, since they’re easy to take down with a hand plane or sandpaper later.

I cut it on my table saw crosscut sled with a flat-top blade — but you can use any saw blade and clean it up with a rabbeting plane.

Aluminum 2024-T4 is a moderate- to high-strength alloy that offers good fatigue resistance and fracture toughness. It isn’t as strong as 7075-T6, but it’s still suitable for aerospace applications.

Typically, heat-treatable aluminum alloys form as the aluminum atoms and alloy element atoms naturally combine during the aging process at room temperature. However, in some cases, this process is artificially induced through aging in a furnace set at a low temperature.

An “injection cycle” can refer to different processes depending on the context, but one common meaning of injection cycle is...

MIC 6 Aluminum possesses a unique combination of alloy and casting methods, specifically designed to produce stable, high-tolerance plates. Its exceptional stress-relieving properties, accuracy, and machinability make it a highly sought-after option for machining components, electronics, and laser technology. Additionally, it is contaminant- and porosity-free, providing a smooth and lightweight choice.

5-axis machine Aluminum Extrusion Atomic Layer Deposition Automation in Injection Molding black oxide finish Chemical Vapor Deposition CNC Machine CNC machining CNC Milling CNC Prototyping Compression testing Designs for Injection Molding DFM Extrusion Welding Fatigue testing Friction Spin Welding Friction Stir Welding Gas-assisted Injection Molding Hardness testing High Pressure Die Casting Injected Material Injection Mold Injection Molded Liquid silicone injection molding Make Plastic Molds Medical CNC Machining Metal 3D Printing Metal injection molding Multi-shot Injection Molding Physical Vapor Deposition Plasma Electrolytic Oxidation Plastic Injection Defects plastic injection molding Powder Metallurgy Powder Metallurgy process Rapid Injection Molding Screen Printing Selective Laser Melting Shore Hardness Simulation Software Six-Axis Robots Surface finish Urethane Casting Vacuum Casting Waterjet Cutting

Aluminum alloys that are not heat-treatable are created by combining aluminum with alloying elements prior to any heat treatment. The initial strength of these alloys is achieved through the addition of these elements. Non-heat-treatable alloys include pure aluminum alloys, manganese alloys, silicon alloys, and magnesium alloys. To further enhance the strength of these alloys, various cold-working and strain-hardening processes are utilized.

I’m with Terence Hughey (Jan 24) — the page could certainly use a PRINT PAGE function because when I’m working in the shop, I’d like to have printed directions. Youtube is nice, but it’s not on hand when in the shop, and I get more out of printed directions anyway.

I’m with Terence Hughey (Jan 24) — the page could certainly use a PRINT PAGE function because when I’m working in the shop, I’d like to have printed directions. Youtube is nice, but it’s not on hand when in the shop, and I get more out of printed directions anyway.

With your show side facing you, bring your coping saw blade into the outside edge of a tail and cut away toward the next tail.

Heat-treatable alloys are comprised of a combination of metallic and non-metallic components, including pure aluminum that is heated to a specific temperature before alloying elements are added uniformly. This addition of alloying material causes the aluminum to solidify, albeit still at a high temperature, after which it is rapidly cooled through quenching. This rapid cooling can cause the atoms of the alloy elements to solidify in place.

Steeper angles like 1:6 give more strength to a joint in softwoods (in theory). The 1:8 angle gives a slimmer look, and because hardwoods are much stronger, it has plenty of hold.

When doing a decorative box with these dovetails is there a recommendation on how to finish the corners? My concern is a round over bit, even a small one, will cause the dovetail to distort or tear out because of the different grain patterns. Do you just keep the edges sharp?

The most commonly utilized aluminum grade in CNC machining is known for its exceptional processing capabilities, high toughness, good mechanical properties, good corrosion resistance, absence of deformation post-processing, easy color film formation, and excellent anodizing effects. It is one of the most common aluminum alloys used in the industry. This aluminum grade is used in various industries, including truck manufacturing, building construction, shipbuilding, tram manufacturing, furniture production, precision machining, and a broad range of industrial applications.

I myself am a huge fan of the tiny pins. Nothing proves they’re hand cut like a gap a router dovetail bit couldn’t fit into.

NOTE: This can be a tad confusing if you're just getting started. Nothing wrong with skipping this step and using a ruler to lay out your tails.

Without making any marks, walk the dividers across the end grain until one of the legs passes the other marking knife line.

Dovetailingmeaning in cooking

Traditional automobile production processes are stamping, welding, painting, and assembly in 4 steps, generally, the steel plate is stamped into small parts

If you don’t have a jointer or planer, a shooting board and hand plane makes squaring the ends of boards by hand super simple. Here’s a great video on how to make your own.

Starting with your show side facing you, make a light stroke in the non-cutting direction to establish your cut (push with a Japanese saw, pull with a Western saw).

If you’re using my dovetail jig, slide the tail side up against your saw after you’ve done your backwards stroke. Hold the jig steady and let the saw and magnets do the work.

There isn’t a right or wrong way to design your dovetails. Play around with different ideas and figure out what you like best.

HOW TO CHOOSE DOVETAIL ANGLESDovetail angles are usually expressed as ratios — the most common being 1:6 and 1:8 (said “one in eight,” and also written as 6:1 or 8:1).

Novice woodworker. Completely intrigued by dovetail joints. Great step-by-step, thanks. Gotta ask tho, about the little brass mallet. Where can I get one ?

The “through” means the pins and tails are visible on both sides of the finished joint (unlike half-blind dovetails, where they’re only visible on one side).

Nice step by step JKM! I’ll share this link with folks I know wanting to do better at hand cut dovetails! I’d also add that no matter what approach one takes, square boards and plumb cuts are more than necessary – PRACTICE MAKES PERFECT!!

Once you have your bevel or combo square set, mark a line from the outside edges of your tails down to the marking gauge line.

0086-813-8127573

0086-813-8127573