Threading Tech Provides Answers to the Right Questions - carbide insert material codes

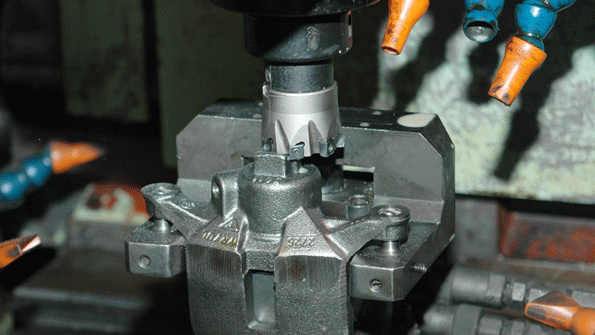

At its automotive brake plant in Elizabethtown, Ky., Akebono became one of the first companies to apply tangential milling (TM) to production of smaller parts. Originally, Ingersoll developed the TM design mainly to improve hogging wide flats on large automotive castings and steel parts, and offered cutters no smaller than 4 inches. Recently, it introduced TM cutters in 1- and 2-in. diameters.

Machining the open construction and lightweight materials characteristic of sandwiched composites involves very low cutting forces, so high-torque machine tool spindles are often unnecessary. However, most sandwiched composite parts are big, such as expansive aerospace wing skins, and the machines that cut them are very large in size as well as powerful.

The improvement stems mainly from the tangential orientation of the inserts in the cutter, Ingersoll’s Konrad Forman explained (see Fig. 2). “Unlike conventional radial cutters, the inserts in a tangential tool lie flat in the pitch circle, presenting the insert’s strongest cross section to the main cutting vector and converting shear stresses to more manageable compressive forces.”

High cutting speeds, however, generate heat, and that poses problems because many of the constituents of sandwiched composites are heat-sensitive. Accordingly, light radial engagement—on the order of 5% of cutter diameter-minimizes heat generation. For the same reason, feed rates are kept low. Despite the light engagement and low feed rates, high cutting speeds help maintain productivity.

Another milling family, EPX, is intended mostly for machining carbon fiber reinforced polymers (CFRP). This family of compression end mills features opposite cutting edge directions—a combination of right and left helix along one flute. This progressive cutting edge geometry reduces delamination and improves tool performance when milling CFRP and the technology is especially recommended for increased feed rates.

Tool geometry can also enhance productive machining of sandwiched composites. For instance, Seco’s Jabro 860 end mills are engineered specifically to machine these types of composite materials. The tool’s double-helix tool flute configuration eliminates fiber breakout, prevents delamination, and improves part edge finishes. As the Jabro 860 rotates, the flute helix on the lower part of the tool forces material upward while the upper helix forces material down. The opposed and balanced cutting forces make for a clean-cutting action.

Of course, cutting-edge security matters a lot in every machining operation, but never more than in synchronous machining cells or carousel arrangements. Sudden tool rupture or edge breakdown at one operation can affect the entire process. Moreover, the risk of failures is often the main cause of extra operator attendance.

A carbide blank is slotted and filled with diamond powder. The carbide blank is inserted into one of Precorp’s high-pressure, high-temperature presses and subjected to 270°F (132.2°C) and 876,000 psi (60,398 bar). In this process the diamond powder is compressed and the diamond crystals are bonded to each other and to the carbide blank. The PCD nib is then brazed to a solid-carbide shank. The braze is located sufficiently far away from the tip of the tool to avoid any potential thermal damage. This allows the use of a high-temperature high-strength braze joint between the nib and the carbide shank. The drill geometry is ground to produce the finished PCD tool. This patented process allows for many tool geometries that are impractical and/or impossible using conventional PCD insert processes.

The most challenging operation is milling out the main yoke slot. Previously, this had been done by roughing in a multi-pass cycle with a conventional zero rake cutter using eight square inserts, and finishing with a separate tool. Sudden edge breakdown during roughing was an accepted part of the production process, even after radically reducing stepovers to avoid pounding. Ironically, the lighter stepovers required more passes, causing work hardening that punished the tool even more.

Net Surfing to Longer Edge Life — At Busche-CNC in Albion, Ind., a simple retooling de-bottlenecked the rough turning operation for difficult-to-machine wrought 5130 and hardened 4140. Previously, cutting edges cratered after an average 20 pc on the 5130; toolbars snapped every other day. The Ingersoll Hex-Turn inserts improved edge life nearly 10 to 1, and eliminated completely the unpredictable, cutting-edge rupture and all the hazards and disruptions that followed.

For milling applications, the versatile Multi-Master tool system, with interchangeable heads, features a carbide head with brazed PCD tips. Due to this innovative design, a machined composite workpiece experiences less loading and swarf evacuation issues and surface finish is improved. The main applications for these tools are orbital milling, edging, and ramping down.

Running 24/5, Busche uses seven two-lathe turning cells to produce 2.75 million/year automotive ring gears in a 400-person shop. Operations there include OD turning, ID turning and facing. As any Tier 2 automotive supplier knows, this is a very competitive business, turning on pennies per part and rock-solid delivery.

Like corrugated cardboard, a sandwiched composite is comprised of a lightweight core structure, usually resembling the hexagonal cells of a honeycomb, backed by rigid facing sheets. Depending on strength requirements, the honeycomb cells may be formed from high-tech paper, cardboard, carbon-fiber-reinforced plastic or aluminum. The face sheets can be paper, plastic, aluminum or titanium and are bonded to the open ends of the honeycomb cells. A balance of bending, compression and shear forces among the elements of sandwiched composites, results in materials that are lightweight, rigid and remarkably strong.

Composite materials for aerospace applications may include polymer matrix composites for structural components for frames and ceramic matrix composites for engine applications. “Ceramic matrix composites developed by GE, Pratt & Whitney, and Rolls Royce for the newest aircraft engines pose special machining challenges,” said Linn Win, industry specialist composites, Sandvik Coromant (Fair Lawn, NJ). “The ceramic matrix composite material is extremely abrasive and very brittle. Adding to the difficulty in machining is the required lightweighting. When you factor in the practical machining for light-weighting applications, it’s very difficult to get the cost savings benefits from the light-weighting components because of the more expensive tooling that is required for complex components like blades and blisks,” said Win.

Now, a single tool completes both roughing and finishing. Moreover, the machining operation has been able to raise its feed rates and throughput by 50% on the wrought stock, and 50% on the hardened material — with no trade-off in edge life.

Old, ‘loose’ machines are torture for cutting tools. They create an ideal setting for chatter to start, which can create excessive impact forces on the tools leading to sudden tool rupture.

To make a short story long, the tangential inserts ran through 127,000 parts – four months – before requiring a change due to edge wear and deterioration of surface finish. That amounted to an 18-to-1 gain in edge life.

Many managers in manufacturing operations regard these types of failures as unavoidable on tired equipment, or they keep cutting back on parameters and stepovers, hoping to find some stability.

That was the case in the machining-assembly cells at a high volume universal joint manufacturer that turns out 60,000 units a year. Each cell contains a vertical CNC mill and a lathe, plus assembly and inspection jigs. All the chipmaking machines are showing their age.

Iscar’s EPN-F family of solid-carbide end mills feature cutting edges that are divided into sections. This design results in better distribution of load on the end mill and machined workpiece, and thus provides increased tool life and improved surface finish, especially when machining carbon fiber and honeycomb composites.

There’s more: It wasn’t until two days into the test that an operator realized that the vibration alarm hadn’t gone off even once. The new, smaller TM tools smoothed out the cutting action just as the larger ones have for decades.

Industry is examining different methods of machining sandwiched composites, including waterjet and other abrasive cutting methods. All the alternatives have advantages and disadvantages. The bottom line is that flawless machining of sandwiched composites, especially those intended for aerospace applications, is crucial. Any imperfection on the skin of the wing can be a crack initiation site, and vibration and other forces in the aircraft will cause a crack to grow. In the interest of reliability and safety, manufacturers will continue to employ the cutting tools and techniques that have been developed and proven over time when machining sandwiched composite materials, concludes Seco’s Graham.

Even without raising throughput rates in the cells, the shop reported it achieved savings of $80,000/year in tooling and tool-servicing costs. The only edge failure mechanism now is predictable flank wear, with zero rupture in more than a year.

For the hardened 4140 stock, the feed is cut back only slightly. In each case, the DOC is backed off for the finishing passes.

The primary reason for the big improvement in cutting-edge security is the Hex-Turn insert’s stronger geometry, according to Ingersoll turning product manager Ed Woksa. “On the one hand, the insert has a 45-degree lead angle that thins the chip and reduces notch wear,” he explained. “On the other, the hex shape is closer to a true round, intrinsically the strongest shape due to the absence of stress-raisers.”

Positive rakes and helical cutting edges on the inserts combine to create a smooth cleaving action, all leading to a much more secure process even on a loose machine.

For instance, a 0.500″ (12.7-mm) diameter Seco Jabro 860 solid-carbide end mill at a 10% radial engagement would run at a speed of 400 sfm (121 m/min) with a feed rate of 0.005 ipt (0.13 mm/t). Such parameters would apply to a sandwiched composite material with an internal Ti-Al honeycomb structure.

“Operations in cells must run in lockstep,” said Ingersoll’s Konrad Forman, “so it’s doubly important there to achieve longer, more predictable edge life on the tooling. “Take any failure root-cause other than gradual wear as a wake-up call to find a better tooling solution, even on a loose machine or any other in unfavorable condition.”

As part of continuing efforts to offer lighter, stronger, more cost-efficient products, manufacturers develop and apply high-performance workpiece materials. Sandwiched composites are good examples of that trend, according to Don Graham, manager of education and technical services at Seco Tools LLC (Troy, MI). Here is Graham’s assessment of the current state of composites machining:

Sharp end mill cutting edges and high cutting speeds are key factors in cleanly machining sandwiched composite materials. The situation is much like slicing bread—cut too slowly, and the bread compresses instead of shearing cleanly. While on the other hand, fast-moving, sharp cutting edges generate clean cuts. When machining sandwiched composites, slow cutting speeds can distort the face sheet and the honeycomb structure itself.

Polycrystalline diamond-veined tooling is a technology that has proven to be very effective for machining composites. “PCD is great for its wear resistance properties in composite machining applications, which may lead to longer tool life, but in order to gain the full potential of PCD, the tool will need to have positive cutting geometries,” said Win. “Conventional brazed tooling, which involves brazing a PCD wafer into a pocket, at best allows for minute positive formations, not the optimum for machining composites. PCD-veined tooling produced by Precorp, a subsidiary of Sandvik Coromant, enables PCD cutting tools to be manufactured with the high rake angles and helix angles required to effectively machine composites.

“PCD diamond-veined tools can be applied to almost every type of machining operation,” said Win. “With structural products for the frame, I think it’s a little easier. What I found in drilling carbon fiber and titanium stacks is that once you clear the carbon material and encounter the titanium material interface, the titanium chips will sometimes score the composite material, again potentially causing a quality issue. To alleviate the problem, we’ve adopted a micro-peck technique in the drilling cycle that allows the formation of smaller titanium chips to clear. In regards to the amplitude of the micro-peck, we are talking on the scale of millimeters. The peck distance is going to be around 0.1–0.2 mm at a frequency of 1.5 to 2.5 micro-pecks in a 360° rotation. What the micro-peck technique does is break up the titanium chips during a drilling cycle and allows for proper evacuation of the smaller more manageable chips. The result is that we’re cutting both materials—the composite and the titanium—with one diamond-veined tool.” Sandvik Coromant is developing a new 88 series geometry PCD-veined tool for CNC applications and a new 86 series for power-feed tools.

Akebono produces the brake calipers in an auxiliary machining cell that feeds a traditional transfer line (see Fig. 3). Because the whole operation is synchronous, there’s no way to speed up a single operation without unbalancing the whole line.

SUMOCHAM for composites is suitable for use on any type of machine-tools such as CNC machines, robots, and even powered feed machines (ADU) for which special thread connectors are available. The fast head replacement and high positioning repeatability provide minimum machine downtime. Relatively small indexable drilling heads with diamond coating provide an economic advantage, compared to long full solid-carbide drills, as well as easy stock management. The SUMOCHAM range for composite materials covers today a diameter range from 0.250 to 0.500″ (6.35–12.7 mm).

This retooling was essentially a drop-in replacement. The only processing changes were to modify the program to increase feed rates, decrease the scheduled stops for indexing, and write out all the steps associated with a separate finishing operation that is no longer needed. Standard parameters for roughing the 5130 are now 900 sfm, 0.0250 IPR, 0.150 DOC.

Soon after the test, Akebono transferred the idea to four more, “small” roughing jobs at the Kentucky plant, and it alerted the other plants worldwide as well. “For a global company in such a competitive business, the faster the good news spreads, the better,” Alvey said.

Aerospace manufacturers, in particular, rely heavily on sandwiched composite structures in critical components such as aircraft wing skins, fuselage sections, cabin walls and floors. However, machining a stack of materials of differing strengths and physical properties presents several layers of challenges. The main goal is to avoid bending or fraying the core structure or delaminating the face sheets. Sandwiched composite material that is cut unevenly or deformed loses its strength, much as creasing corrugated cardboard destroys its rigidity.

Further complicating machining are that stacks of materials of differing strengths and physical properties can be combined in layers for highly specialized and targeted uses. According to Kennametal’s Composite Machining Guide fiber reinforcement materials include carbon fiber/graphite fiber, glass fibers, ceramic fibers, polymer fibers, and tungsten fibers. Polymer matrix materials include epoxy, phenolic, polymide, and polyetheretherketone (PEEK).

Due to the wide array of applications, no two CFRP materials are exactly alike. Each composite can take on different characteristics by changing the matrix formulation, fiber type, content, orientation, build-up, and the method of forming, according to Precorp.

One troublesome operation in the cell is rough milling a 1.1-in. hose mounting area on the caliper. It’s an interrupted cut that cratered cutting edges and often set off the machine’s vibration alarm. “We were getting 7,100 parts per edge with a conventional 4-pitch cutter, and we were satisfied,” said Terry Alvey, Akebono central purchasing manager of indirect materials. During a plant visit, however, Ingersoll field engineer Paul Nugent spotted the operation and the opportunity to do better. He explained the TM concept and suggested a trial run for the new 2 inch S-MAX tangential cutter.

Also aiding smoother cutting was the higher insert count in the cutter, made possible by the tangential design. The new 2-inch tangential S-MAX has seven inserts, versus four in the previous 2-inch cutter. “Under the same parameters, more inserts means lower cutting forces on each one,” Forman explained.

Iscar Metals Inc. (Arlington, TX) has developed a new range of tools, both indexable and solid-carbide, for machining composite materials. Because intensive abrasion of a cutting tool can lead to dramatic deterioration of cutting tool geometry and, as a result, to performance problems, Iscar R&D has focused on wear that can cause delamination during drilling and milling operations. In order to significantly improve the cutting tools’ performance during drilling, Iscar has developed a solution based on interchangeable heads of its SUMOCHAM product line. The new ICF drilling head geometry, which has been especially designed for drilling composite materials, provides low axial forces for smooth penetration during the cutting process without splintering phenomenon. The new heads are based on a new carbide submicron substrate and diamond coating for prolonged and predictable tool life.

Machining characteristics of CFRP/CFRP and CFRP/metal materials are impacted by the abrasiveness of fibers, by fiber size, fiber diameter, fiber length, volume of fibers (percentage), and fiber layout, unidirectional or fabric weave. For example, abrasiveness of fiber increases with strength and diameter. Short fibers tend to delaminate, as do unidirectional layered composites. To counter the tendency to delaminate, Kennametal has developed compression-style routers that generate cutting forces at top and bottom of the materials’ surfaces, as well as other tools including burr-style routers, down cut-style routers, and ball end routers.

Iscar also offers a range of solid-carbide drills, starting from 0.118″ (3 mm). The tool geometry of the CFD family has been designed with a stepped point and with two working sections, considerably improving surface finish and allowing a smooth cut on very difficult-to-machine composites, like RTM or thermoplastic materials.

“Especially in cells and carousels, the number-one priority in tool selection should be zero tool rupture or edge breakdown,” said Konrad Forman, North America milling tool manager for Ingersoll Cutting Tools. “Unless you are replacing an edge due to gradual wear only, you are missing an opportunity to improve cell-wide efficiency -- and even to run unattended.”

Sandwiched composite parts typically are flat or mildly curved panels that range in thickness from 0.250 to 0.500″ (6.35–12.7 mm). The panels are fabricated to near-net-shape and finish-machined to trim outer edges, mill out widows and other various shaped openings and holes. For finish machining, shops must use high-speed end mills specifically designed for such sandwiched composites.

Now, the shop gets the job done with a modified, standard Ingersoll S-Max tangential milling cutter that has increased edge life by a predictable 10 to 1 and eliminated all the pounding, even at the original higher material removal rates (MRRs). Since the tool is size-matched to slot width and has corner radii, it takes fewer passes to complete the slot and the singular tool does both the roughing and finishing.

“We have found that in drilling applications in ceramic matrix composites, we do not encounter too many issues when entering the material; the problems occur when we exit the material. On the exit surface, we find that the breakout can be quite poor, due to the high axial pressures that are being applied to the workpiece upon the tools exit. The back side of the material in an unsupported environment tends to blow out, which may lead to quality issues. In an unsupported application, we believe there is not an effective way to machine ceramic matrix composites, due to the materials inherent brittleness,” said Win. “But what we have found is that when we apply positive tool geometry with the PCD-veined diamond tooling, you can actually reduce the amount of stress forces that being applied because now you have freer cutting edge and are able to produce the features that are needed with lower thrust force.”

This article was first published in the September 2016 edition of Manufacturing Engineering magazine.

The components of sandwiched composites can be abrasive, so the tools used to machine them usually are manufactured from micrograin carbide to maximize edge integrity and wear resistance. To further resist abrasive wear, some cutting edges receive diamond coatings. Seco’s DURA thin diamond coating, for example, is applied via CVD and combines low surface roughness for lubricity with high adhesion characteristics that reinforce its wear resistance. The coating requires a balance in tool engineering in that it is thin enough to minimally affect sharpness but thick enough to provide resistance to abrasion.

“The application also illustrates the benefits of modified standard tools,” Forman said. “This is basically a standard tangential mill made in a special size and with special radii, not a complete ‘special,’” he added. “It brings the production benefits of a ‘special’ in a high-volume operation with the supply-chain security of a ‘standard.’”

Carbon fiber reinforced polymer (CFRP) composite materials deliver the important performance advantages of high strength-to-weight ratio, durability, and extreme corrosion resistance in lightweight structures, valued especially for demanding aerospace and oil and gas industry applications. Difficulty of machining can vary significantly depending on the combinations of matrix material and fiber reinforcements selected. Due to the wide array of applications, no two CFRP materials are exactly alike. Each composite can take on different characteristics by changing the matrix formulation, fiber type, content, orientation, build-up, and the method of forming, according to Precorp Inc. (Spanish Fork, UT), a company since 2013 in the Sandvik Coromant organization.

The switch was from 80-deg rhombic inserts to Ingersoll Hex-Turn inserts. “I found them the day they hit the market because I regularly surf the ‘net for new solutions we can use,” said Jerry Busche, vice president.

18581906093

18581906093