YG-1 opens subsidiary in South Africa - yg carbide end mills

Imaginary circle that touches all sides of an insert. Used to establish size. Measurements are in fractions of an inch and describe the diameter of the circle.

Structure of a metal as revealed by microscopic examination of the etched surface of a polished specimen.

Manufacturers tasked with cutting these alloys quickly learn that following traditional machining guidelines alone will not keep them competitive. Cutting tool manufacturers are familiar with these difficulties and are poised and ready to offer a productive and cost-effective alternative: ceramic composite cutting tools.

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

The feed rate is expressed as ACT instead of feed per revolution or feed per tooth because the chip thickness can vary in relationship to the feed rate, depending on many factors. When applying a round insert, for example, the ACT depends on the DOC, because the effective lead angle changes as the DOC changes, varying the thinning or thickening effect on the chip.

A Danish manufacturer of precision tooling relies on programming technology an essential “tool” for its own strategy to supply specialty solid-carbide tools to the global market. From a 2,000-m2 shop near Copenhagen, TN Vaerktoejsslibning has established a global reputation for product quality and precision – handling every phase of manufacturing and tracking the movement of individual tools from initial order through to delivery, and exporting about 70% of its output.

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

In addition, coated, whisker-reinforced ceramics introduced in the last decade provide additional time and cost savings compared to their uncoated counterparts. The addition of high-performance coatings increase an insert’s temperature and wear resistance, much like coatings on carbide cutting tools, and further boost productivity and tool life.

The major benefit of phase-toughened ceramic is its ability to retain strength in demanding, high-force, interrupted cuts and excel in continuous cuts. Machining forging and casting scale and highly abrasive materials are just a few of the application areas these inserts are designed for.

To further illustrate this difference, the rule-of-thumb starting parameters for turning Inconel 718 with a round, uncoated, whisker-reinforced ceramic insert that has a ½" (12.7mm) IC is called “the rule of eight”: a cutting speed of 800 sfm (244 m/min.), a feed of 0.008 ipr (0.20 mm/rev.) and a DOC of 0.080" (2.03mm). This results in a mrr of 6.14 in.3/min. (100.6 cm3/min.).

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

An interesting aspect of TN Vaerktoejsslibning’s operational structure is a flat organization: there is no design department. Each CNC machine operator is responsible for programming, grinding the tools, and fully documenting the process.

Proper cutting speeds and feed rates vary, depending on the composition of the material being machined. In addition, it’s particularly important to pay attention to the material’s hardness. A harder material requires a lower cutting speed than a softer material to plasticize the parent material to the point where a tool can efficiently remove it.

High cutting speeds are crucial for plasticization, or softening, of HRSAs, so material can be efficiently removed layer by layer. The plasticization process, however, generates a high level of heat in the cutting zone, which needs to be effectively managed and evacuated so the microstructure of the parent material is not compromised. Because of this, it is essential to properly balance the cutting speed with the feed rate and maintain the correct average chip thickness (ACT) to ensure the bulk of the heat is carried away with the chip.

Implementing CCCTs is not as simple as placing an insert in a pocket and hitting the green button. Users must understand the basic science behind why these tools are capable of such performance gains and how to accurately gauge and adjust for tool wear.

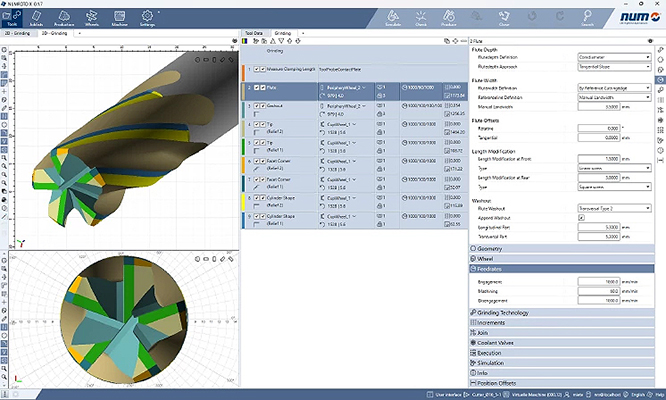

TN Vaerktoejsslibning regularly enhances its machining capabilities to meet customers’ changing needs for tools and functions. It started using NUMROTO software in 2002, when it purchased two Deckel S20 CNC grinding machines, which have since been followed by 10 more Deckel S22 machines. The current complement of NUMROTO-controlled CNC grinding machines consists of the 12 Deckel machines, plus a UWS SF40 cylindrical grinder and two Vollmer VGrind 340S machines.

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

Another benefit of phase-toughened ceramics is their ability to operate across a wide cutting speed range. The traditional method would be to rough HRSA parts with carbide because of a limited rpm or the limitation of an older piece of equipment that would not allow the use of whisker-reinforced ceramics. In the past, those who simply could not use ceramics now are finding they can apply the phase-toughened ceramic. Cutting speeds can be as low as 450 sfm (137 m/min.) and be combined with a slightly lighter feed rate of 0.008 to 0.010 ipr (0.20 to 0.25 mm/rev.) at the same DOC when applying the same phase-toughened ceramic insert, bridging the gap between carbide and ceramic cutting tools.

One of the most widely known CCCT materials for cutting HRSAs is whisker-reinforced ceramic. When introduced more than 30 years ago, whisker-reinforced ceramic tools took the market by storm by providing up to 10 times the productivity of carbide. Without the whisker reinforcement, ceramic cutting tools of the time lacked the predictability to excel at machining HRSAs. Whisker-reinforced ceramics continue to excel at machining these difficult-to-machine materials.

A rule of thumb for whisker-reinforced ceramics is to have an ACT of 0.002" to 0.004" (0.05mm to 0.10mm). This will ensure the chip maintains the proper cross section to carry the extreme heat developed by high cutting speeds from the tool/workpiece interface.

As the demand for more fuel-efficient gas turbine engines continues to escalate, traditional heat-resistant superalloy (HRSA) materials are being replaced with new ultratough, high-temperature and wear-resistant alloys. The physical demands on these materials are high—as are the demands on the cutting tools applied to machine them.

CCCTs are specifically engineered to combine extreme temperature resistance with high strength. This combination provides a highly productive and predictable cutting tool material capable of withstanding the extreme conditions encountered when machining HRSAs and other challenging materials.

In business since 1987, TN Vaerktoejsslibning maintains a maintains a large inventory of high-quality “subnanograin carbide” materials in the form of rods with internal cooling channels and solid bars, ranging from 2 to 70 mm diameter. Using multiple CNC grinding machines, TN Vaerktoejsslibning produces a comprehensive range of standard “TN” brand high-speed end mills, step drills, and form cutters – the design and dimensions of which can be tailored to customers’ needs, “the right tool for the job.”

According to founder, owner, and CEO Torben Nielsen: “We try to make work as interesting and satisfying as possible for people, and over the years we have built up a dynamic team of highly qualified and committed employees. Another important point is that by standardizing on NUMROTO for the bulk of our CNC machining operations, we benefit immensely from our employees sharing a common pool of expertise and knowledge about state-of-the-art tool production technologies and processes. Many of our more specialized tools are only required in small batch sizes – sometimes just two or three – and yet we aim to supply these to customers within the same, nine-day timeframe as our standard tools.

It’s important to know that phase-toughened ceramic inserts cannot be run like other ceramics on the market; increased feed rates are a must. If the feed rate is not high enough, a high level of flank wear will occur, leading to premature tool wear. The ACT for phase-toughened ceramics is generally much higher than that of whisker-reinforced ceramics and many SiAlON (silicon aluminum oxynitride) materials.

A new ceramic composite material that is gaining favor for turning and milling HRSAs is phase-toughened ceramic. Offering almost twice the strength of whisker-reinforced ceramics, this new ceramic composite can be run at the feed rates used for carbide inserts with the cutting speeds common with ceramic inserts. In addition, the increased strength of a phase-toughened ceramic tool can triple productivity, compared to other ceramic composite tools.

Whisker-reinforced ceramic inserts are made from fine-grain alumina oxide, combined with silicon-carbide crystals, commonly called whiskers. Al2O3 is a high temperature- and wear-resistant material but lacks strength and, therefore, predictability. By adding silicon-carbide whiskers, Al2O3 is reinforced and becomes predictable and strong, much like rebar in cement or fiber filaments in fiberglass. This reinforcement allows the ceramic tool material to operate at much higher cutting speeds than traditional carbide tools.

Angle between the side-cutting edge and the projected side of the tool shank or holder, which leads the cutting tool into the workpiece.

On average, by upgrading from an uncoated to a coated, whisker-reinforced ceramic tool, users can expect a 20 to 40 percent increase in cutting speed. And depending on the grade of the coated insert, up to a 20 percent increase in feed and up to a 50 to 100 percent increase in tool life can also be realized. In many applications, a coated grade imparts a finer surface finish and allows a longer length of cut than an uncoated grade.

When switching from a whisker-reinforced ceramic insert to a phase-toughened ceramic one, a slight speed reduction is typically necessary, but the feed rate can be greatly increased. Data illustrates that 700 to 750 sfm (213 to 229 m/min.), 0.014 to 0.016 ipr (0.36 to 0.41 mm/rev.) and 0.080" to 0.120" (2.03mm to 3.05mm) DOC creates the sweet spot when cutting Inconel 718. This results in an mrr from 9.4 in.3/min. (154.2 cm3/min.) to 17.3 in.3/min. (283.5 cm3/min.) when conditions are ideal.

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

Creating too thin of a chip will not carry enough heat away and, therefore, heat will be transferred into the parent material. In addition, having a chip that’s too thin causes an insert to rub the part instead of cutting it, leading to rapid flank wear and, ultimately, premature tool failure. Too thick of a chip has the opposite effect, increasing pressure on the insert, which leads to chipping and breakage.

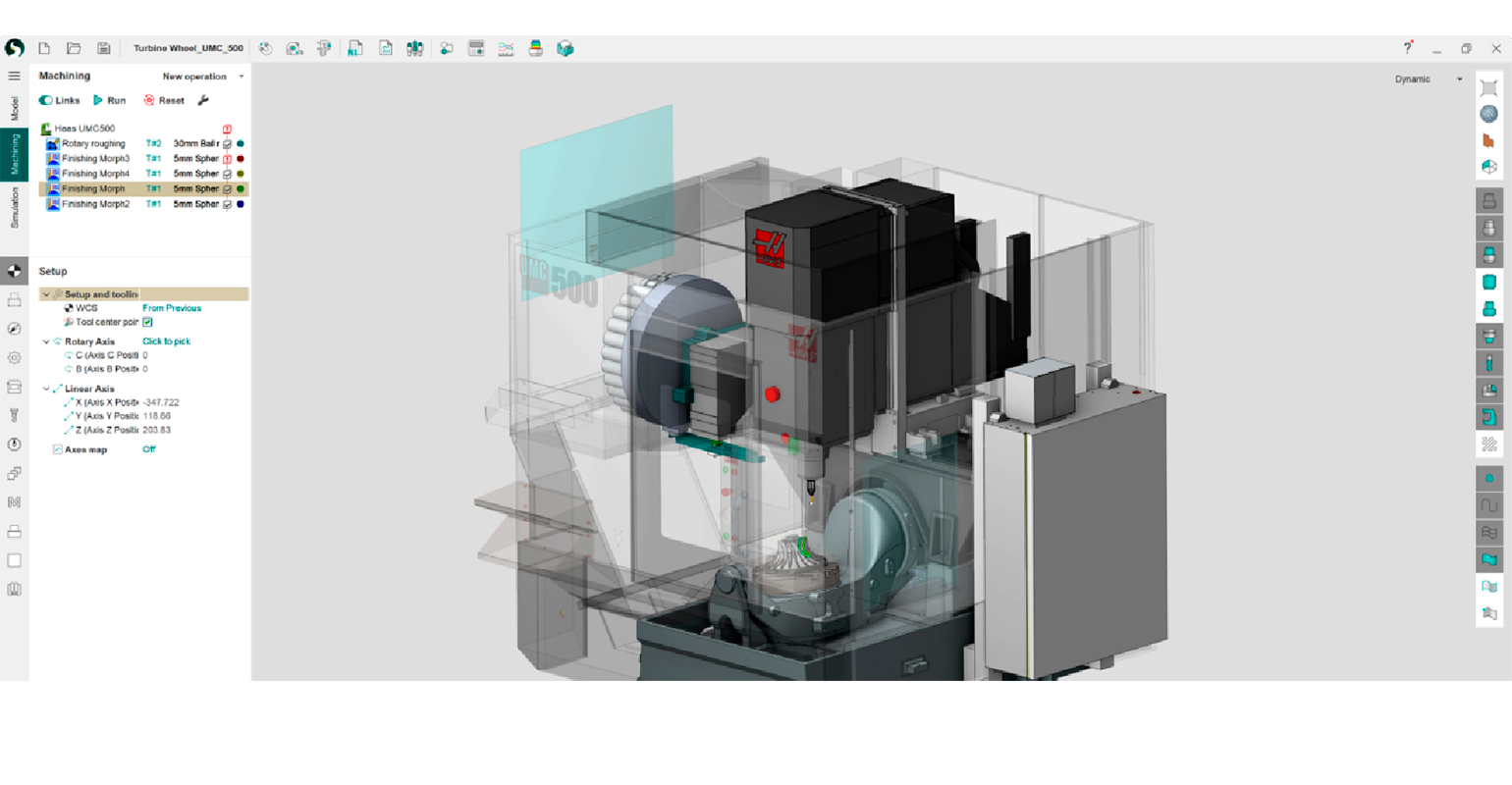

Every aspect of tool manufacturing at TN Vaerktoejsslibning is extensively automated. The main workshop has 15 five-axis CNC grinding centers, complemented by cylindrical grinding machines. Now, all of these machines are controlled by NUMROTO software and are networked together to help simplify production management and software maintenance. Each machine has a dedicated programming station, so part programs can be created while grinding is underway, and TN is in the process of expanding its multi-user programming facility, up from the present seven users.

What does all of this mean for manufacturers who must process these heat-resistant superalloys? If baseline productivity can be increased as much as 10 times with whisker-reinforced ceramics, compared to carbide tools, throughput can be greatly increased—freeing up machine time to run more jobs on the same equipment and reducing tool costs, as well as overhead costs and capital expenditures.

Cutting tool materials based on aluminum oxide and silicon nitride. Ceramic tools can withstand higher cutting speeds than cemented carbide tools when machining hardened steels, cast irons and high-temperature alloys.

The programming and machining of special tools, which constitute the majority of TN Vaerktoejsslibning’s production output, usually is carried out during the day by skilled operators. Larger standard tools are processed at nighttime, using robotic part loaders and unmanned machining centers for lights-out production, but with a high degree of feedback such as in-process measurement and run-out compensation to ensure consistent product quality.

All tools produced by TN Vaerktoejsslibning undergo thorough inspection prior to shipment. The company’s quality assurance facilities include an air-conditioned, positively pressurized measuring room, equipped with a five-axis CNC measuring machine and other precision optical measuring equipment.

“To help meet this goal, our operators need fast, simple and unambiguous machine control facilities – which in turn demand very flexible, accurate and reliable software, with a modern user interface,” Nielsen added.

Add to that productivity increases achievable with coated, whisker-reinforced ceramics or the new phase-toughened ceramic, and the potential productivity gains are significant. With the broad application range of these ceramic composite cutting tools, there is virtually a solution for all manufacturers of HRSA parts, as well as those tackling other challenging workpiece materials.

“Our experience with NUMROTO has been fantastic,” Torben Nielsen offered. “The software is perfect for grinding both simple and highly complex tools and is extremely reliable. It is very easy to work with and the simulation is very precise. In a period of just over 21 years, there have been very few tools that we have been unable to create. Due to our very short delivery times, we rely on good support – and this has always been forthcoming from NUM.”

So far, the only phase-toughened ceramic available is Greenleaf Corp.’s XSYTIN-1. It is a thermally stable, whisker- and particulate-toughened silicon nitride with almost twice the strength of any other commercially available ceramic tool from Greenleaf.

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

Reduction in clearance on the tool’s flank caused by contact with the workpiece. Ultimately causes tool failure.

Jim Wyant is an applications engineer for Greenleaf Corp., Saegertown, Pa. For more information about the company’s cutting tools, call (800) 458-1850 or visit www.greenleafcorporation.com.

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

When using a straight-edge insert, the ACT depends on the orientation of the tool to the part, otherwise known as the tool’s lead angle. While machining with a lead-angle tool can be beneficial for many reasons, such as reducing ceramic notching, it is important to adjust the programmed feed rate to account for these chip-thinning phenomena and ensure a predictable tool wear pattern.

TN Vaerktoejsslibning also operates advanced in-house tool polishing and coating technology. Tools can be coated both before and after polishing, optionally, to extend service life and help to optimize chip evacuation. It also offers regrinding and recoating. Provided that a tool not physically damaged, it can often be returned to full service after regrinding and possibly recoating, for less than 50 percent of the cost of a new tool.

18581906093

18581906093