Alpha No. 20 for 5/32inch Rivets Double Ended Drill Bit ... - 5 drill bit

I both love and hate the camera on the xTool P2. The positive side of it is the smarts: It uses AI to locate the edges of your material to better help you align your designs. This means you can use the offcuts of other projects, put them in the machine and let the camera orientate your designs to best fit in that space, saving you from a lot of wasted materials. Unfortunately, the downside to the camera often makes this hit or miss.

Hardened steel is resistant to wear and high-impact pressure, making it a choice material for applications that require hard-wearing materials. These characteristics can also make it challenging to machine hardened steel. Read on to discover the best drill bits for drilling into hardened steel.

Be warned: You need a huge amount of room for the conveyor belt, and cutting something all the way through could cause jams. It's best to leave a small tab to hold it in place that can be trimmed off once the cutting is done. I didn't use the conveyor much in my testing -- my workshop isn't set up for passthrough cutting -- but if you build your workspace to accommodate it, I can see the conveyor reducing labor time immensely.

Hardened steel is medium- or high-carbon steel that has been given heat treatment, rapidly cooled and tempered. The high amount of carbon in the steel makes it possible to harden the metal.

Another excellent time and material saver is the software. It allows you to use almost any image file, though DXF and SVG are always best, to etch or cut. It offers several ways to take an image and cut it out to remove backgrounds, making the cuts and etches far cleaner. This is great if you've drawn something on paper and need to convert it to a digital file. You can take a picture, and use the xTool software to convert it to a usable file. The software also has a fledgling AI image generator that will generate images from text prompts. So even if you don't have the artwork you want to use, you can have xTool generate it for you. It also has a QR code generator, which is helpful if you want to add business details to your designs.

When the xTool first arrived, I was taken aback by the weight and quality-feeling parts it had. I've used other laser cutters and few of them have a premium finish like the P2. Simple things make all the difference: There's a pneumatic lid, so it doesn't slam into the machine if you close it, and an LED that turns from blue to green when the door can be opened safely. These touches bring the P2 more in line with the Glowforges of the world, rather than the cheap knockoffs.

The lack of display on the P2 is somewhat confusing. All it really has is a temperature gauge and a big "push to go" button. I wish it had more of a display so I could do repeat cuts, or check the progress with more precision but the software does a fairly good job of that. One omission of the software that I find odd, however, is that it doesn't tell you how long your project will take to cut. You can't gauge if you have time for that project or if you need to do something smaller. It's a pain I didn't think would matter to me, but if you're using the P2 for your business, time matters.

These drill bits can be tungsten carbide tipped or full body. Carbide-tipped bits can drill through hard, non-metallic materials like masonry. If you want to drill hardened steel with tungsten carbide, use a full-body bit.

Cobalt drill bits are often the best for drilling into hardened steel. Whereas titanium drill bits only have titanium in the coating, cobalt bits have cobalt throughout. After cobalt drill bits get worn out over time, you can resharpen them.

The more cobalt the bit contains, the harder the metal it can drill through. But the tradeoff is that increasing the cobalt increases the drill bit’s brittleness. Be sure to use the appropriate drilling techniques to preserve your cutting tools.

Working in different materials is easy. I made this LED by cutting an image of Squall's Gunblade from clear acrylic and then etching the quote on an LED stand from Amazon. The stand was too thick for the normal cutting platform, but the xTool has a setting that allows you to remove the slats in the base making it deeper, allowing you to cut and etch thicker materials. There is a laser level that helps set the cutting laser to the right height, so you always get the right amount of burn. Mixing materials to create projects is what makes a powerful laser like this stand out from the crowd.

The P2 has other large-scale tricks up its sleeve too. With an additional conveyor belt system, the P2 can effectively cut an infinite length, limited by the heat of the laser and how well it can keep cool. So it could be used to either cut or etch something very long like a sign or lots of small cuts for mass production.

Titanium drill bits are one option for drilling hardened steel. These drill bits are high-speed steel bits coated with titanium nitride. High-speed steel bits that consist of vanadium and tungsten can drill through soft steel, but they won’t cut through hardened steel.

I write a lot about 3D printing, often called additive manufacturing, but there's also a different way to create called subtractive manufacturing. Laser cutters like the xTool P2 cut away material to create cool art and can be used on a massive variety of materials from wood sheets to the top of your MacBook. The P2 is one of the larger laser cutters I've used, and while it's expensive, it can be a gateway to changing your hobby into your career.

Our expert, award-winning staff selects the products we cover and rigorously researches and tests our top picks. If you buy through our links, we may get a commission. Reviews ethics statement

(In case you're wondering, the pumpkin pie turned out great. The pumpkin around the cut tastes a little burnt, but it works!)

Once the physical setup is complete, you'll need to connect the P2 to your computer. Unfortunately, this has to be done physically the first time, by plugging it directly into a PC or laptop. This was an issue for me as my maker PC is in my office, but if you have a large workspace with a PC already, you should be fine. After the initial setup, the P2 is happy to work over a wired, or wireless connection, which is great, as there is no direct interface on the machine itself.

The machine is heavy, yet delicate. This is not a one-person lift at all. Make sure you have a team of people to help you put the xTool P2 in place because once it's there, it's there for good. Given that the P2 can be used with a conveyor system, you'll need to make sure there's room at the front and the back if you're thinking of using it that way.

Cobalt drill bits contain an alloy of five to eight percent cobalt. M35 bits contain approximately five percent cobalt, and M42 bits contain about eight percent cobalt.

Lasers are fun and exciting and can make amazing things. Small artistic businesses should invest in the P2 from xTool to make everything faster.

Pro Tip: The laser uses CO2, which requires cooling, so part of the initial setup is filling a reservoir with antifreeze and water. Use distilled water, not tap water. The impurities in tap water will damage the machine over time.

If you’re looking for a tool to cut through hardened steel, check out the cobalt drill bit sets at Drill Bit Warehouse. Our premium M42 drill bits come in various lengths to suit your project needs. Shop with us today for high-performance drill bits.

While the xTool boasts two cameras to help you align your materials correctly, those cameras have a fish-eye effect that curls the corners farthest away from them. This makes lining up your design to perfectly fit your material almost impossible. If you're using a 12-by-12 inch piece of wood you can expect to lose around a quarter of an inch on either side to make sure the P2 doesn't cut outside the material area.

The titanium nitride coating has a dark gold appearance, improves wear resistance, and reduces friction. Since the titanium nitride is just a coating, once your drill bit wears down, you cannot resharpen it and maintain its performance level. The titanium layer will no longer be on the drill bit except in the fluting and perhaps on the sides.

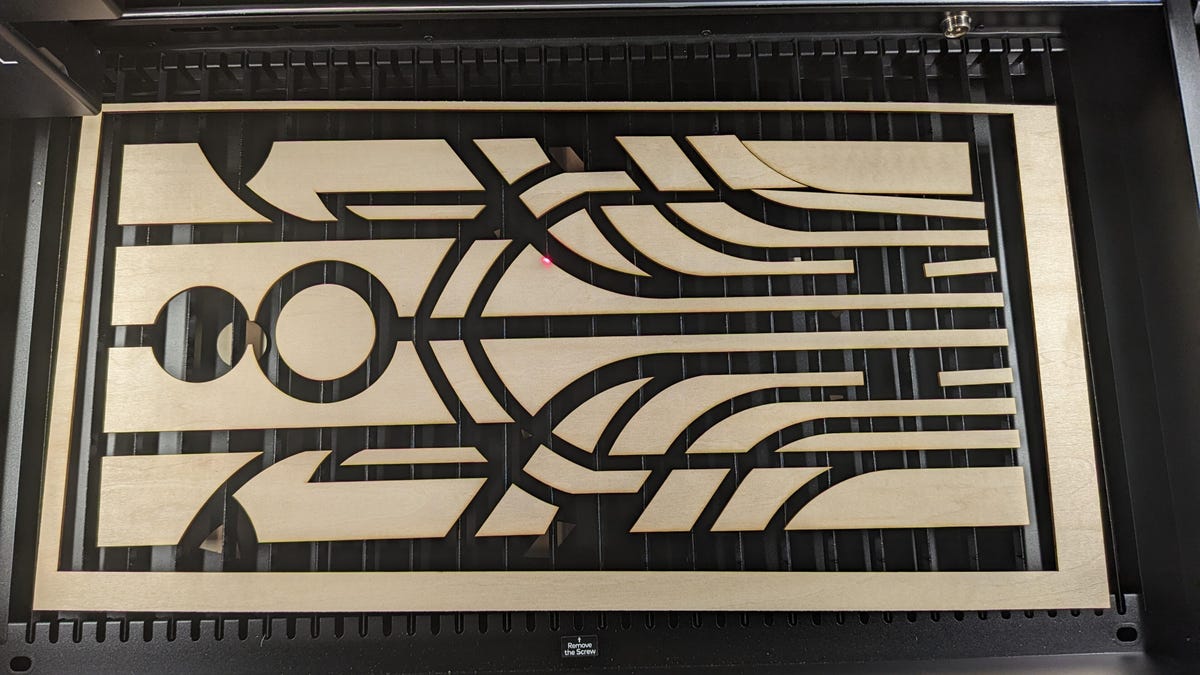

When it comes to materials, there's very little that the P2 can't cut -- or at the very least, etch. It can cut 20mm thick clear acrylic, something that's notoriously tough for lasers to cut, as well as just about all woods at 20mm thick. Most of your materials are probably only going to be 3mm or 6mm, but having the option to cut thicker pieces lets you score thick wood deeply. I tried it out on wood, cardboard, two different types of acrylic, brass, anodized aluminum, glass and even a pumpkin pie, and the P2 handled everything with near-perfect precision. I especially liked how well it was able to etch the glass lid from one of my 3D printers with the CNET Logo. It gave the printer a far more premium look.

Carbide is a compound composed of carbon and a metal. Carbide drill bits are tungsten carbide and can contain cobalt for enhanced durability. Carbide drill bits can handle higher temperatures than cobalt drill bits.

More and more of us are looking to make our hobbies into a side hustle. The best 3D printers let you make things you can sell on Etsy, or at local craft fairs and they're an easy return on investment. The P2 from xTool is the natural progression for someone moving from a hobbyist to something more substantial. Yes, it's $4,500 for the base model, or nearly $6,000 for all the bells and whistles, and for a hobbyist that's a significant chunk of change. If you're a business though -- and one that's growing well and has fresh ideas -- that's a solid investment that will lead to greater profits in the long run.

Every job I threw at the P2, from simple etching on glass to a multitude of complex cuts and scores on acrylic, was handled with speed and accuracy. My colleague is currently testing a smaller laser cutter, with a low-powered laser and the difference is remarkable. We both cut the same wooden book, using the same cutting file, and the same images on the front and back. While the P2 managed the entire cut in 21 minutes, his took a whopping 207 minutes (3 hours and 27 minutes). This is why CO2 lasers are used commercially. Completing a job 10 times faster than a cheap laser means you can get more product out of your doors.

18581906093

18581906093