From Impossible to Reality: Researchers Create First Functional

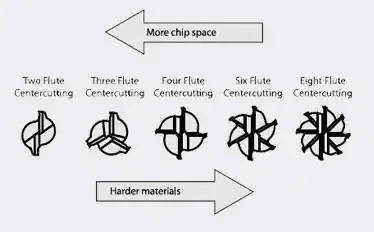

But, in addition, if your work can accept the radiused edge, they will also give a finer finish than a square end mill. Even if you have to use a square end mill as your finisher, it will last longer if the rough cut was performed with a corner radius end mill.

One of the most common problems you can see is poor blending of corner radius end mills. If the radius in not tangent or more commonly referred to as an “undercut” or “step”. Avoid corner radius end mills that have a step visible on the radius.

Yes. In other words, they’re good for both. The corner radius makes the cutting edge less susceptible to chipping, which makes them ideal for roughing. In fact, many cnc machinists insist on bull nose end mills when roughing, especially on tougher materials.

Specifying a corner radius end mill in G-Wizard is simply a matter of setting the Corner Rad. field to the corner radius.

While they cost a bit more than normal square end mills, the extra cost may be worth it in terms of potential higher performance and longer tool life.

A Corner Radius End Mill can run with faster feeds and speeds than a square end mill. You can use our G-Wizard Feeds and Speeds Calculator to figure out just exactly how much faster they can go.

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

Corner radius end mills also called bull nose end mills) are normal square end mills that have a slight radius ground into their edges. The radius helps distribute cutting forces evenly to prevent damage to the end mill, which extends its life.

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

18581906093

18581906093