Carbide Insert Market to Hit US$ 1,586.71 Million By 2030 | - carbide insert manufacturing

The segment will register around 8% CAGR during the forecast period. These equipment are used in mining, construction, oil & gas, and metalworking industries.

North America will grow by a CAGR of around 7% from 2018 to 2025. Developments in the country’s automotive, aerospace & defense, and oil & gas sectors will propel the tungsten market value in coming years. Latin America and Middle East & Africa regions have much lower product demand when compared with other regions. However, these regions will have a high industry growth rate during the forecast period.

Is your requirement urgent? Please give us your business email for a speedy delivery!

Groove or other tool geometry that breaks chips into small fragments as they come off the workpiece. Designed to prevent chips from becoming so long that they are difficult to control, catch in turning parts and cause safety problems.

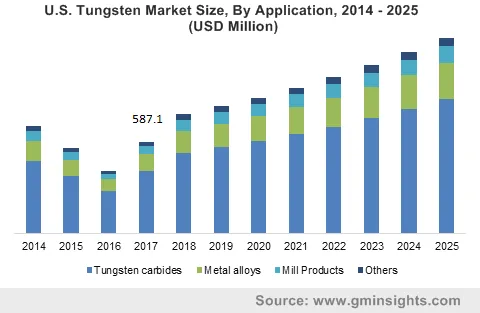

Based on application, global market has been segmented into tungsten carbide, metal alloys, mill products, and other applications such as salts, tungstates, sulfides, oxides, etc. Carbide is the largest application segment and is likely to grow with a CAGR of around 8% during the forecast period. Increasing usage of these products as drilling, boring, and cutting tools in various industries will drive the tungsten market.

Tungsten market research report includes in-depth coverage of the industry with estimates & forecast in terms of volume in tons and revenue in USD thousand from 2014 to 2025, for the following segments: Click here to Buy Section of this Report

Based on end-use, the global tungsten market is segmented as automotive parts, aerospace components, drilling, boring & cutting equipment, logging equipment, electrical & electronics appliances, and other end-uses including chemical, defense equipment, etc. Drilling, boring and cutting equipment is a major end-use sector in the product market.

Global Market Insights Inc. 4 North Main Street, Selbyville, Delaware 19975 USA Toll Free: +1-888-689-0688 USA: +1-302-846-7766 Europe: +44-742-759-8484 APAC: +65-3129-7718 Email: sales@gminsights.com

Most of the companies in the market are integrated across the value chain and are involved in raw material production, processing as well as manufacturing of finished products.

In addition, Top Cut 4 is featuring high-stability shanks in lengths of 2XD, 3XD, 4XD, and 5XD, in both metric and inch configurations. Diameter ranges from 12 to 68 mm (0.473 to 2.5 inches). Eight insert sizes cover the complete diameter range. The cutting edge profile of the central and periphery inserts works together, leading to high stabilization of the drill, preventing tool drifting even on irregular surfaces.

Aerospace components is also an important tungsten market end-use sector which is poised to grow by more than 7% CAGR during the forecast period. The product is extensively used in manufacturing aerospace components such as rotor blades, propellers, inertial systems, fluid control systems, bucking bars, trim weights, aircrafts balance weights, and many more.

Asia Pacific, having accounted for more than half of the product demand in 2017, is poised to grow by more than 8% CAGR. The regional industry will be chiefly driven by China, which is the largest producer as well as consumer of the product. High growth in China’s automotive, aerospace, mining, and electronics sector will be the major factor behind its dominant tungsten market position.

Looking for more? Our expert team of researchers can create market analysis reports for any of your needs.

![]()

“Process stability is a significant challenge and the driver behind Top Cut 4 and its development,” says WIDIA Product Manager Vivian Pavlov. “What process stability simply means is the ability to quickly select and successfully apply a tool even in an unfamiliar or unstable condition. Users need one drill that can be applied in a variety of drilling operations and workpiece materials. Top Cut 4 addresses this challenge with cutting performance at higher speeds, which makes it the proven choice in lowest cost per edge.”

Robust cutter bodies are marked by deep helix angled flutes for efficient chip evacuation even at 5XD length. Large coolant holes mean efficient coolant delivery and extended insert life.

1. Process of locating the center of a workpiece to be mounted on centers. 2. Process of mounting the workpiece concentric to the machine spindle. See centers.

Tungsten carbide is the most popularly used form of the product which has hardness close to diamond. It is denser than steel and titanium, twice as hard as any steel grade, and has extremely high wear resistant. Due to these characteristics, the product is widely used in construction, mining, and metalworking applications.

Expanded capabilities and improved performance combine for outstanding results in the new Top Cut 4 indexable holemaking platform from WIDIA. A true multi-problem-solver in one platform, Top Cut 4 is targeted to end users that need one drill that can be applied in a variety of drilling applications and different workpiece materials. Top Cut 4’s breadth of application capabilities include through- and cross-holes, inclined entry and exit opportunity, 45º corner, half-cylindrical, concave, and chain drilling. And four true cutting edges combined with WIDIA-grade technology results in notably higher speeds and feeds, higher metal-removal rates, and extended tool life, all of which means lower cost per edge.

Tungsten Market size was estimated over USD 3.5 billion in 2017 and the industry will grow by a CAGR of around 8% through 2025. Increasing product deployment in different end-user industries such as automotive, aerospace, defense, electronics, oil & gas, mining, etc., will augment the global market.

It is used in lighting technology, electronics, power engineering, automotive & aerospace sectors, coating & joining technology, medical technology, and many other important industries worldwide.

The market may face challenges from the huge demand-supply gap over the past years, causing a significant drop in the product prices since 2014. This led to a fall in the global market size in terms of revenue, and the manufacturers underwent losses in order to balance the demand-supply dynamics. Though, the prices stabilized after 2016, leading to a rise in the market size, the level of uncertainty may pose hindrances in tungsten market share over the coming years.

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

Majority of the product is used in manufacturing cemented carbides or hard metals. These are materials made by cementing tungsten carbide grains in a binder matrix of a tough nickel or cobalt alloy using the process of sintering.

Since its discovery in the middle ages, tungsten or wolfram has been used by humans for a wide range of applications. The tungsten market makes an important contribution to a country’s economy, through its use in high-speed steel tools and cemented carbide, and by helping to achieve high productivity levels in manufacturing industries.

Top Cut 4 periphery and center inserts each feature proprietary cutting profiles for excellent centering capability and workpiece penetration. The inner and outer (center and periphery) inserts are clearly differentiated for no mixups, and are available in grades for high-speed applications, high toughness demands, and high metal-removal rates in general. Specific geometries are available with such features as reinforced cutting edges and a steep chipbreaker for steel, cast iron, and short-chipping materials, or an optimized chip groove for stainless steel, long-chipping steels, and where low power consumption is required.

The mining sector is a key end-user for the product, especially for carbides. Numerous industries worldwide depend on the supply of commodities from the mining sector. The top 40 companies, which represent a vast majority of the global mining industry, generated around USD 600 billion of revenue in 2017.

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

Mill products segment accounted for around one-tenth of the overall market. The segment’s demand is likely to grow by more than 7% from 2018 to 2025. Mill products are pure tungsten metal products such as electrodes, lighting filaments, electrical & electronic contacts, sheets, wires, rods, etc. Developments in the electronics industry will be the major factor driving the mill tungsten market growth during the forecast period.

This would increase the demand for tungsten carbide because it is widely used in the mining industry in manufacturing top hammer rock drill bits, roller-cutters, downhole hammers, raise boring reamers, long wall shearer picks, long wall plough chisels, tunnel boring machines, etc. With increasing demand for precious metals in China and other developing countries, the global mining industry is likely to maintain an upward trend in coming years and will propel the tungsten market growth.

Home > Chemicals & Materials > Advanced Materials > Functional Materials > Tungsten Market

The new Top Cut 4 indexable drilling platform from WIDIA is targeted to end users that machine a broad assortment of products and need one drill for a variety of drilling applications and workpiece materials.

18581906093

18581906093