Carbide Insert Market to Hit US$ 1,586.71 Million By 2030 | - carbide insert manufacturing

Precision cutting tools are in great demand in aircraft, automobile, and medical device manufacture. In addition, advanced materials and technologies like composites and titanium alloys demand precise and efficient cutting tools. Businesses use cutting-edge cutting tools that may relate to robots and other automated systems to optimize output and save costs. Thus, cutting tool technologies like sensors and data analytics allow real-time monitoring and optimization of cutting processes. Sustainability and environmental responsibility also drive demand for energy-efficient and waste-reducing cutting tools. Due to stricter rules and requirements, companies actively seek cutting-edge techniques to reduce their carbon footprint and satisfy ecological objectives.

“The thing I’ve always liked, especially coming from the inspection side of the cutting tool industry, and that a lot of customers like, is doing in-process gaging and in-process inspection with a presetter. There are things that I can qualify—diameters, lengths, runouts, radii, concentricity—and we can do DXF overlay profiles if necessary. If an operator wants to do some verification, it doesn’t take that much longer after presetting the tool. They can then be assured that the tool is qualified and will make a good part.” — Matt Brothers, Industry 4.0 Tech Center manager, Zoller

We value your investment and offer free customization with every report to fulfil your exact research needs.

One factor behind the rise in the popularity of shrink-fit toolholding is high-speed machining, also known as high-velocity milling, said Olivier Branget, application engineer for tooling systems, Seco Tools LLC, Troy, Mich.

Brothers said he’s even seen some people do presetting with calipers. “There’s even some ways of doing it on the machine tool where they have different gages, touch-off probes and lasers,” he said. “But then all you’re using the machine tool for is a presetter, not making chips. [That’s why] it’s always nice to have that done offline.

“It certainly is growing in popularity,” said Brendt Holden, president of Haimer USA, Villa Park, Illinois. “We’re seeing more and more companies adopt the shrink-fit technology. Initially it started with [some] die mold [and] some high-speed machining applications that aligned with aerospace or medical-type work. What we’re seeing now is shrink-fit in the general machining markets.” This includes automotive production facilities, sub-suppliers of parts and the general market. “Shrink-fit is fast and reliable but if it wasn’t providing better toolholding in the machine tool, where the machine tool can run more efficiently, we wouldn’t even be talking about it,” he said.

However, the growing prevalence of cutting tools in many industries like automotive, aircraft, and others is leveling up the market shares in North America.

Cemented carbide is a popular cutting tool material due to its longevity, hardness, and strength. Turning, milling, drilling, and threading employ it. Hence, the cemented carbide segment prevails in the cutting tools market.

Brothers described how room for error is introduced when using a separate shrink-fit unit and presetter. “In the touch-off method, the procedure is to zero out the encoders, bring it down, touch it off and look at the distance that it traveled,” he said. “Then, you’ll go to the table and type in the value. But there is the risk of typing in the wrong number.”

The two-in-one machines may also be a boon to speed, accuracy and safety. “You’re going to get more setting accuracy in the tools, you’re going to have a faster preset cycle time, and it’s also a safety thing as well because you’re not handling any sharp objects,” said Zoller’s Brothers. You’re not taking the chance of dropping these heavy tools if one was to have shrinking and presetting done separately.”

“What most people do, they’ll take a scale, a ruler let’s say, and they’ll say ‘I’ve got this sticking out 4"’,” Holden said. “They’ll put a magic marker mark on the shank of the cutting tool (and use that to set the tool). And that’s good enough. They might bring it to a standalone presetter at that point and take their final Z dimension and that’s all they’re looking for. Now that’s not very sophisticated, admittedly.”

If the same tool is going to be used over and over and there is concern about clearance, shops should shrink-fit and preset the holder, then insert a backup screw for a repeatable Z axis, Holden advised. Haimer, Seco and Zoller machines also have a rod the operator can insert through the center of the toolholder that functions just like the backup screw.

Enabling high-speed machining, in addition to holders with stronger clamping forces and reduced runout, are more complex algorithms in computer-aided machining software, Ball said.

Manufacturing, notably automotive and electronics, has grown in the region, increasing the demand for cutting tools in the market. Major manufacturers in the region are also increasing their market share. Due to manufacturing industry investments, the cutting tools market in Latin America, the Middle East, and Africa is expected to expand. In addition, construction and oil and gas development in these locations will boost cutting tool market size.

“I know places do that, but I’d be concerned about changing the material structure of the holder,” said Alec Janson, product engineer II, OSG USA Inc., Irving, Texas, about quenching the holder. “Not that it would be too much but you’re dealing with something that’s supposed to be precision equipment.”

That problem is solved with automated data transmission. Zoller has an option, data output, where if there’s a networked or USB port or if the machine is capable of accepting a file from a post-processor, the operator can do the presetting and generate the same machine code with the offsets. It inputs all the right information into the proper pockets. As a result, the operator doesn’t need to type anything.

While the basic concepts behind shrink-fit toolholding—heating expands and cooling contracts—have remained the same since its inception in the 1990s, companies responsible for the technology behind it have improved their machinery and processes. Apocryphal stories remain about using a blow torch to expand the inner bore, and some shops still quench a heated tool holder in a bucket of water and coolant to prompt contraction, but now there are much safer and more controlled ways to do both.

“If your toolholder loses its shine and becomes black and dull instead after repeated shrinking, it was probably made of inferior material.” — Brendt Holden, president, Haimer USA

Brothers’ company also has another product option called »zidCode«, which prints out a QR code that the operator can scan for the offsets that will input the information in the table as well. “That’s growing in popularity,” he said. “It’s quick data input and you’re eliminating data transfer errors.”

“That’s a tried and true practice that works great,” said Janson. “The issue is if you get a tool that’s less than 1 mm in diameter, especially end mills and square end mills, you start to have concerns about the potential of chipping from that. That’s the concern we have when we’re dealing with stuff of that size. So, we typically use a presetter.”

Along with advanced technology for heating and chilling, some operators favor using a shrink-fit unit that is designed for presetting. And presetters are favored by shops running specific types of machine tools. “The people who really gravitate to those machines (presetters) are those with multi-spindle machines,” Holden said, noting there are milling machines with two or four spindles as well as single-spindle machine tools. “All four spindles are running the same program at the same time. So, they need to make sure all four of the tool angles are the same on the Z axis.”

Janson said his criteria for whether to use a presetter depends on the application, the tool size, the level of precision required and the need for speed in production.

Cutting tools shape metal, wood, plastic, and other materials. These hand-held or piston-powered instruments serve a purpose in many sectors. Saws, drills, reamers, taps, end mills, lathe tools, milling cutters, and grinding wheels are cutting tools. Material, finish, and precision determine the cutting tool. Due to a growing demand for high-quality, precise instruments that could boost productivity and efficiency, the cutting tools market is a sector of the economy expanding quickly. In addition, cutting tools have improved in sophistication, tensile strength, and efficiency with the introduction of new technologies and materials.

Induction coils solved a problem at Seco in the early 2000s, Branget said. At the time, some tools—typically those with smaller diameters and also ones made of solid-carbide inserts in steel shafts—were getting stuck in shrink-fit holders because the method used to expand the internal bore was so slow that it heated the tool at the same time. The thermal coefficient of the holder and the shank was the same. Today, induction systems are so powerful you can heat up the holder enough to expand it before the tool gets hot, said Branget.

The market is segmented into milling tools, drilling tools, turning tools, grinding tools, and others. Among these, milling tools hold the largest share due to their extensive use in various applications.

“With a lot of the harder materials, Inconels and titanium, a higher grip force is needed so the tool doesn’t spin inside the holder,” said Matt Brothers, Industry 4.0 Tech Center manager for Zoller Inc., Ann Arbor, Mich.Consistency in setup among operators is the No. 1 draw for shrink-fit toolholding, according to Holden. “To put a cutting tool in a toolholder in a shrink-fit chuck [is the same] if you are working in a shop for two weeks or 20 years,” Holden said. “Whereas if you’re using a collet chuck or other systems, the guy who’s been working there forever, he’s an expert. He knows how to clean out the collets, he knows exactly what to do to get the runout and the better performance while the new guy needs time to get up to speed. In the meantime, you have inconsistent production.”

To meet market demands for precision and effectiveness, companies must engage extensively in R&D, which may be costly. Cutting tools' competitiveness in the marketplace is another key constraint. E-commerce and globalization have given purchasers a wide selection of suppliers and options, making it harder for manufacturers to differentiate themselves and keep market dominance. Manufacturers must spend money and time on branding, marketing, and customer service to compete. 3D printing and additive manufacturing allow the fabrication of complicated parts and components that were hard to make with traditional cutting tools, impacting the traditional tools for the cutting business. Cutting tool makers must adapt to new technologies and combine their products with 3D printing and additive manufacturing. Finally, the global scarcity of competent labor restrains the cutting tools industry. There are fewer competent employees to operate and maintain modern cutting tools as demand rises. Manufacturers must train and retain skilled people, which is tough and expensive.

One big problem that all-in-one machines can create, however, is a line of idle workers. “Sometimes having two machines in one might not be advantageous if someone is clogging up the machine and all you need is a quick in and out of a shrink-fit drill,” Holden said. “It’s holding you up.”

OSG also has a laser mounted in one of its machines that will do automatic tool touch-offs. “It’s kind of like the presetter we have, it’s just within the machine,” Janson said. “It’s used in the same way but a little bit quicker and less manual.”

Why do it? It provides the cutting tool with lower runout, stronger gripping torque, greater balance, slimmer profile, and extended reach options. It also decreases the inventory a shop needs to keep track of and store, improves repeatability, and shortens tool change time.

“This is a really important aspect of shrink-fit,” said Kennametal’s West. “The rapid, controlled heating of the toolholder has to stay within the limits of the material from which the adapter is made. Exceeding the maximum temperature will jeopardize the integrity of the adapter, which in turn reduces grip and runout. It takes its toll on tool life.”

“Even touching off … some people will shrink the tool then bring it down and touch the tool off, but you could damage the part if you don’t have an experienced operator and it could come down and chip the tool,” Brothers continued. “Again, not using the tool to make chips.”

“Presetting is especially important when using reconditioned tooling because the reconditioning process takes a little off the length. Having a good tool management system that uses reconditioning creates the possibility there could be duplicate cutting tools in different reconditioning cycles and therefore different tool heights. Presetting the tool heights eliminates the differences and promotes accuracy.”— Ron West, senior project manager, marketing, Kennametal Inc.

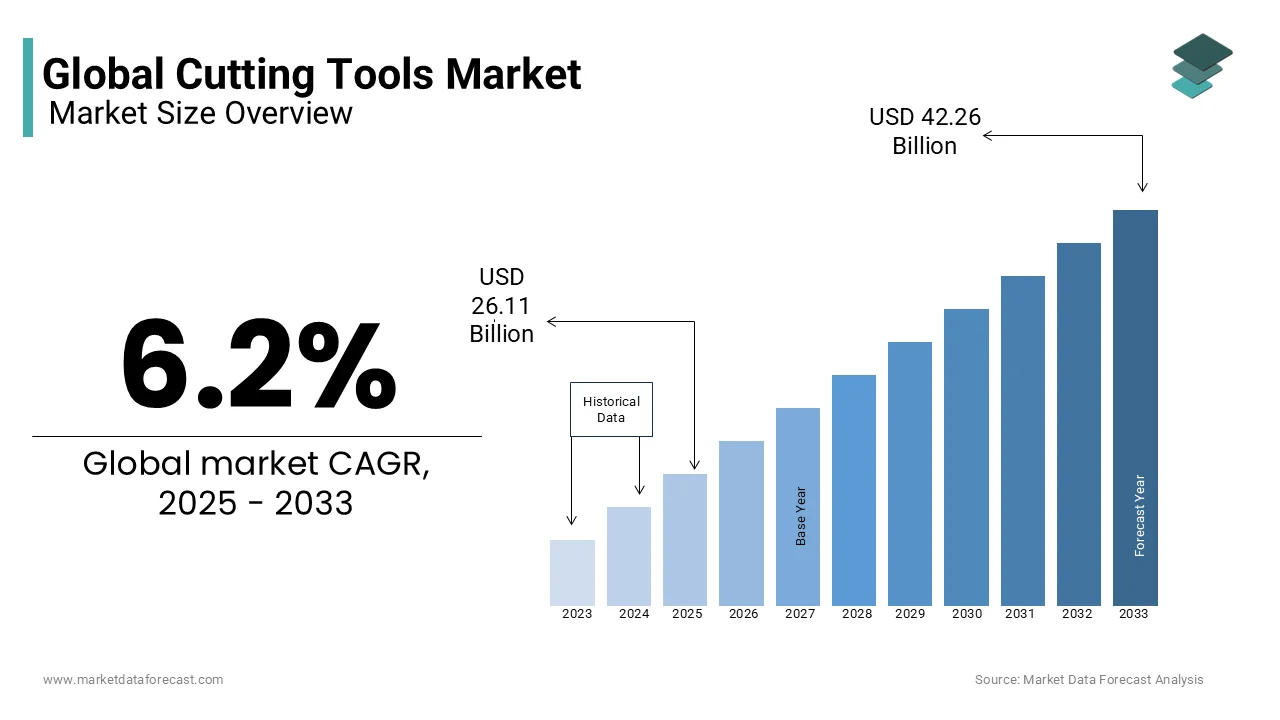

The global cutting tools market is expected to grow at 6.2% from 2024 to 2029 and the global market size is predicted to be valued at USD 24.59 billion in 2024 and increase to USD 33.21 billion by 2029.

“The one caveat that we run into with shrink units is they don’t avoid tool pullout. They’re really good at keeping the tool in place if it’s drilling so you’ve got forces going up into the machine. But in milling, especially aggressive roughing, the way the helix angle on the end mill imparts forces onto the holder you will sometimes see the tool shift by up to 0.015-0.02" (0.381-0.508 mm), which can take you out of tolerance. The tool can get pulled slowly out of the holder. It’s something that all holders can have an issue with. You might be better off with something you don’t have to potentially worry about damaging.”— Alec Janson, product engineer II, OSG USA, Glendale Heights, Illinois

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities

Another failsafe method uses RFID tags. “We check the tool, we write the information to the chip,” Brothers said. “Then we place the unit into the machine tool and it transfers the information when it’s ready to use the tool. Usually in high production [applications], companies use RFIDs just for the sake of repeatability and to decrease errors. So, they don’t have to come back after making a few parts and quality control comes and says ‘this part’s oversized.’”

The market for cutting tools is constantly changing, with new business prospects constantly appearing. The increasing need for cutting tools in the medical and dentistry sectors is one of the most recent industry opportunities. The demand for precise equipment that can handle intricate and delicate tasks is growing as technology advances. Orthopedic surgery, neurosurgery, and dental implant placement are procedures that use cutting instruments.

For those who operate single-spindle machines, 90 percent of them just want to make sure when they put the cutting tool in that they have clearance between the nose of the toolholder and the tip of the cutting tool edge, Holden said.

The automotive industry significantly influences the market as it requires precise and efficient cutting tools for manufacturing complex components. The push towards electric vehicles (EVs) is also driving demand for specialized cutting tools.

Changing the material properties of the toolholder isn’t the only concern. “What we found is [that with] unevenly cooling the tool, shocking the tool, there could be some negative effects,” Holden said, adding that he’s also seen operators pick up a heated toolholder and place it in sand to cool. “[It] could actually induce runout. You want to have even cooling. It’s important.”

BIG KAISER Precision Tooling Inc., Kennametal, Nachi-Fujikoshi Corp., OSG USA, INC., Sandvik AB, Ceratizit S.A., Dewalt, Fraisa SA, Guhring, Inc., Kilowood Cutting Tools, Xiamen Golden Egret Special Alloy Co. Ltd., Zhuzhou Cemented Carbide Cutting Tool Co. Ltd., Tiangong International Co., LIMITED, Ingersoll Cutting Tool Company, Sumitomo Electric Hartmetall GmbH, Kyocera Unimerco, and ISCAR LTD and Others.

The following are tips and tricks of the trade, shared with Manufacturing Engineering by the experts.

Some manufacturers make machines that combine shrink-fitting with presetting. There are pros and at least one con to these. A combination machine requires only one cost justification to the bean counters vs. having to justify the price of two machines. A combination machine can also take up less floor space than a standalone shrink-fit unit and presetter would.

Emerging trends include the adoption of advanced coatings to extend tool life, the use of AI and IoT for predictive maintenance and tool management, and a shift towards sustainable and environmentally friendly manufacturing processes.

“Modern shrink fit machines use preprogrammed heating cycles that are based on the nose diameter of the holder. This ensures uniform heating and consistent holder life by not overheating the holder, which can change the molecular properties, causing the holder to lose its gripping force.”— Jay Ball, product manager for solid milling, Seco Tools

Forget about using the blow torch to get the holder hot enough to accept the tool, said the experts. The common method for applying the kind of heat needed is to use the electromagnetism of an induction coil.

Unlike its name, the use of shrink-fit tooling is expanding. A shrink-fit toolholder starts with a slightly undersize bore that is heated to enlarge the inner diameter enough to accept a cutting tool and then grip the cutter as it cools and contracts.

Metalworking processes frequently employ indexable inserts, including turning, milling, and drilling. They are composed of a tiny cutting edge attached to a larger substrate made of steel or another material, usually made of another hard substance like ceramic or carbide. With indexable inserts, fewer frequent tool changes are required, and efficiency is increased. The cutting edge may be shifted as it becomes worn or damaged. On the other hand, solid round tools are single piece cutting tools produced from a solid piece of material like high-speed steel or carbide. They are employed in several tasks, including drilling, boring, and reaming. Solid round tools are used in high-volume manufacturing processes because of their dependability and accuracy.

Another method for cooling uses a spray of water on the heated toolholder followed by air blown over it or cooled solely with forced air, which Seco shrink fit units do.

In addition to using height indicators and risky touch-offs that can damage the tool in lieu of a presetter machine, Janson said he’s seen one operator place a piece of paper between the tool tip and workpiece. As he lowers the tool, he knows he’s reached the correct height when he can’t pull the paper away.

The expanding need for cutting tools in the aerospace sector represents another market potential. Tools that can work with unusual materials, such as titanium, aluminum, and composite materials, are needed in the aerospace sector. The move toward lightweight materials also drives the desire for cutting tools that can make accurate and clean cuts. In addition, cutting tool manufacturers now have new business potential in the renewable energy industry. Tools that can handle the materials used in these applications are becoming increasingly vital as the demand for wind turbines, solar panels, and other renewable energy technologies rises. The parts of these technologies, such as the blades for wind turbines, are produced using cutting tools. Finally, the demand for cutting tools that can be used with cutting-edge manufacturing technologies like CNC machines and robots is being driven by the rising trend towards Industry 4.0 and automation. Cutting tools with improved geometries or specialized coatings optimized for these technologies are in great demand.

Where Janson works, operators use a touch-off gage (a gage of a known height equipped with a dial to measure distance) set on the workpiece or on the table in the machine. The operator takes the tool, drops it down and touches it on the top surface of the probe until the dial registers the height.

The consistency Holden described helps not only with day-to-day operations, but also when quoting a job, so the shop doesn’t overestimate or underestimate machining time depending on the operator, according to Brothers.

Yet another reason for using shrink-fit toolholding is its compatibility with automated operations, said Ron West, senior product manager, marketing for Kennametal Inc., Pittsburgh. As a result, he sees customers using shrink-fit to facilitate lights-out operations.

Not only could runout be induced with uneven cooling, the tool also could be sentenced to an early death. “You’re changing some of the makeup of the holder and you could decrease the life of the tool,” Brothers said.

Commonly seen in commercially available cooling equipment are sleeves with internal coolant that fit over the heated toolholder and reduce its temperature in a matter of seconds. Instead of sleeves, Seco calls its technology cooling bells.

Drilling and milling tools often employ high-speed steel (HSS). HSS tools resist high temperatures, making them ideal for stainless steel cutting. Due to their great temperature and wear resistance, ceramics like aluminum oxide and silicon nitride are becoming desirable cutting tools. Turning, milling, and drilling require ceramics. Super abrasives like PCD and CBN are used to process hard and complex materials in cutting tools. Aerospace and automotive production benefits from their wear resistance, thermal stability, and accuracy.

“Presetters are another expense, though, so it’s a tradeoff,” he said. “Are you saving more money by saving that time or are you not able to offset that?”

Sandvik AB, Kennametal Inc., Robert Bosch GmbH, Stanley Black & Decker Inc., Mitsubishi Materials Corporation, OSG Corporation, Kyocera Corporation, Guhring KG, ISCAR LTD and Seco Tools AB are some of the major companies in the global cutting tools market.

Engine, gearbox, and body panel output employ cutting tools. Cutting tools are also significant in aerospace and defense. Machining titanium alloys, nickel alloys, and composites need high-precision cutting tools. Due to the rising demand for aircraft and defense equipment, the aerospace and defense industries will require more cutting tools. Construction uses a lot of cutting equipment, especially drilling, sawing, and grinding. Construction, especially in emerging nations, will likely fuel the demand for cutting tools. Cutting tools also serve the wood sector. Wood uses cutting, shaping, and drilling tools. Furniture and other wood goods will likely fuel demand for cutting equipment in this market. The cutting tools market's application segment shares vary by industry and growth prospects. Due to their strong need for precision machining, the automotive, aerospace, and defense industries will continue to demand cutting tools.

Haimer and Zoller have an intelligent coil that can sense the distance from the inside of the coil to the outside of the chuck so it doesn’t exert any more power than needed to heat the holder.

Key drivers include technological advancements in manufacturing processes, increasing demand from the automotive and aerospace sectors, and the growth of the industrial and construction sectors globally.

Branget’s colleague Jay Ball, product manager for solid milling at Seco, explained, “There’s this dynamic shift going on in manufacturing as far as how we process parts and as a result, we’re seeing a lot of high-velocity milling strategies. More and more customers are using larger-diameter carbide end mills, say ½", ¾" or 1" (12.7, 19 or 25.4 mm), to replace larger, helical cutters to be able to get high metal removal rates. The cost can be substantially lower.”

18581906093

18581906093