Kyocera's CVD Coated Cermet grade is designed for finishing applications - cermet insert

Just as Teller discovered, the resources available at OriginLabs, such as the 3D printers, the computer numerical control (CNC) machine, the panel saw, the welding equipment and dozens of other pieces of equipment, are intended for research and development for anyone in the region with prototyping or fabrication needs.

PCD is a matrix of randomly arranged diamond crystals that are bonded to form an extremely hard film or wafer.

Five years into growing and running the business, now with their own manufacturing facility, a team of employees and plans to launch a new product, Teller and Stover have a new Penn State resource to make the prototyping process a lot easier and more efficient the second time around.

This project was financed in part by a grant from the Commonwealth of Pennsylvania, Department of Community and Economic Development.

“OriginLabs will continue to be such a huge resource for us, and it has really performed its function," Teller said. “Expectations somehow always deviate from reality when it comes to the promises that some programs give. But OriginLabs is exactly what they say they are, and it’s that big of a resource.”

Most recently, Teller and Stover wanted to make a modification to their existing finishing equipment. Teller said retrofitting manufacturing equipment is always a necessary, expensive and risky process, but by utilizing the CNC machine at OriginLabs, they were able to eliminate that risk entirely. CNC machines use a computer to automate the precise manufacturing of a target product.

UNIVERSITY PARK, Pa. — When Britta Teller and Evan Stover launched their sustainable hardwood floor startup, Steller Floors, in 2019, they spent a lot of time, energy and resources prototyping and iterating on their products by themselves.

“A lot of people think that, to grow a startup, you have to go to Silicon Valley or some other expensive location to have any type of assistance,” Stover said. “Here in central Pennsylvania, we have assistance from Penn State, which means we didn’t have to go anywhere to figure this out.”

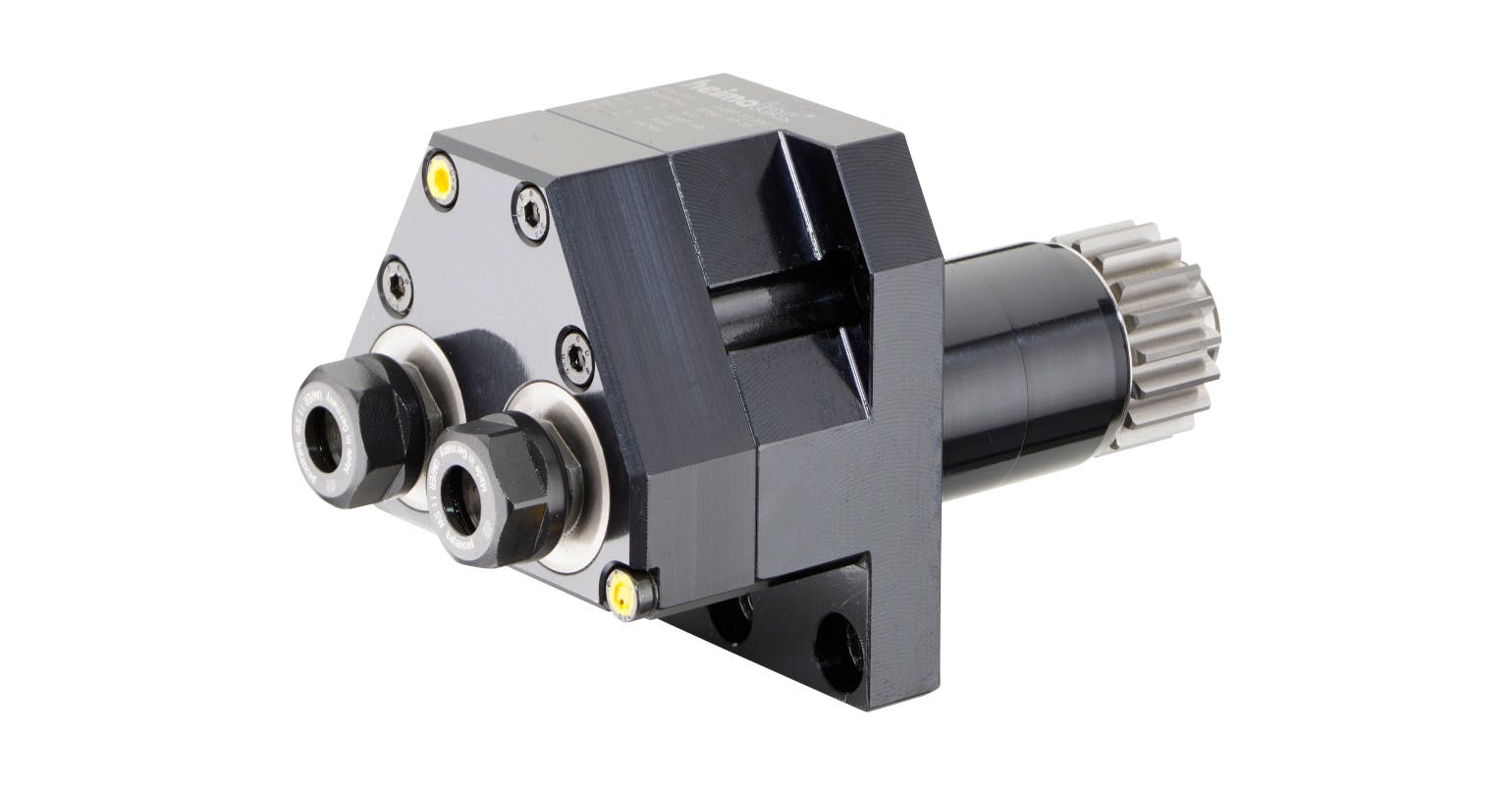

The company said the end mills are extremely durable and can provide 50 times more tool life than conventional carbide end mills. Emuge PCD and CBN end mills are available from stock, in ball nose, torus and flat-end designs, in sizes from 0.1857 in. to 0.500 in. and in metric sizes from 4 mm to 12 mm.

In addition to OriginLabs, Steller Floors has taken advantage of other Penn State resources, including the Pennsylvania Technical Assistance Program, who assessed their air compressor and suggested ways to make their manufacturing process more efficient. Steller Floors has also worked extensively with both Ben Franklin Technology Partners and the Penn State Small Business Development Center on the business and financial side of their company. They have also had entrepreneurial student teams assist them through Penn State Behrend, the College of Engineering and the Department of Agricultural and Biological Engineering.

When it comes to machining hard, difficult-to-machine materials, it’s tough to beat poly-crystalline diamond (PCD), cubic boron nitride (CBN) or ceramic inserts.

When machining Inconel 718, for example, the company said speeds can be increased four to five times compared with cutting speeds when using carbide inserts. The inserts are equally productive in the automotive industry, machining alloyed gray cast-iron brake disks, and in the roll products segment removing casting crust or heavily worn rolling surfaces.

“We’ve maximized Penn State resources, and I’m so grateful. What we’ve done here would not have been possible without the immediate adjacency to the university,” Teller said.

“We would also encourage anyone in the community who wants to start making something to go to OriginLabs and start making it,” Teller said. “I hope having this resource in the region helps more companies innovate, especially here in Blair County. It makes innovation so much more accessible, so anyone working in a manufacturing facility or running a startup who is saying, ‘Shouldn’t this process be different?’ has the option to find out by working with OriginLabs.”

About three years ago, Seco Tools Inc. (www.secotools.com) metallurgists hypothesized that if they could directly deposit the alpha form in the beginning, they could avoid the cracking issue and produce a more homogenous and tougher structure. Eliminating cracks would also make the coating a more effective thermal barrier, reducing the amount of heat getting to the substrate.

Emuge Corp. (www.emuge.com) has announced the expansion of its hard milling end mill line to include new PCD and CBN end mills.

When developing aluminum oxide (Al2O3) coating materials, it is preferable to use the alpha form of for most applications. Unfortunately, it is much easier to deposit the kappa form. Consequently, producers have deposited the kappa form and then heat-treated it in a coating furnace to transform it to alpha. However, this heating process results in an unavoidable contraction in volume, resulting in the formation of cracks in the coating.

These tools effectively machine highly abrasive, non-ferrous materials, including graphite, highsilicon aluminum alloys, fiberreinforced synthetics and copper alloys.

Stover said he has a whole timeline of projects he is planning to work on with OriginLabs, starting with prototyping a new product.

The Steller Floors co-founders and Tyrone natives are now regular users of Invent Penn State’s OriginLabs, a prototyping and fabrication facility located in downtown State College in the Eric J. Barron Innovation Hub intended for community members, small to medium-sized manufacturers, students and faculty alike.

Teller and Stover used the CNC machine to prototype a tray insert to simulate the way Steller Floors’ finishing machine would function if they were to retrofit the equipment.

The tools are pre-engineered and precision manufactured for optimum performance for cutting challenging cutting applications. The PCD shaped cutting edges are affixed to carbide shanks by a sophisticated microwavebrazing technique that forms bonds that are able to withstand temperatures to 1,100° F.

Teller and Stover said their door is always open to anyone who would like to come see what it looks like to be a five-year-old manufacturing startup.

“I have a little filament printer, but it’s just not the same as prototyping a produced piece,” Stover said. “The fact that they have all the different types of top-of-the-line 3D printers is incredible. If I wanted to prototype this piece in metal, I could have OriginLabs make it and see if it would do what I thought it was going to do under a production framework, because it would actually be made from material very similar to that of the end product.”

“When I wandered into OriginLabs for the first time, my jaw hit the floor,” Teller said. “When I walked around the labs and saw all the available equipment, I said, man, whoever gets to use this place is going to be really lucky.”

CBN is the hardest known substance next to diamond, and provides the cutting edge for long-lasting tools that proficiently machine hard steels to 66Rc, as well as hard castings, Inconel, Monel and Stellite.

“To run this test, we needed a lot of those trays, and so to do it by hand would have taken months — it would not have been possible,” Stover said. “And we would have never bought that CNC machine for ourselves, because we wouldn’t have used it again or enough to warrant the purchase.”

Located at the Eric J. Barron Innovation Hub in downtown State College, OriginLabs provides access to world-class prototyping facilities to students and faculty from across campus, as well as members of the public from State College and beyond. The OriginLabs facilities enhance the suite of resources available to researchers, innovators and entrepreneurs in the region in the form of sophisticated equipment, free workshops, and expert advice and technical guidance.

KY4300 inserts are composed of aluminum oxide reinforced with silicon carbide whiskers. These whiskers have high mechanical strength and act like reinforcing steel bars in concrete, improving the strength and fracture toughness of the cutting insert.

They sent the initial drawings to OriginLabs Shop Manager Jose Nunez, had some back-and-forth conversations and iterations, and prototypes were completed within a couple of weeks. Those prototypes are being used today on the manufacturing floor at Steller Floors, resulting in an accelerated manufacturing process and reduced waste for the company.

Ceramic inserts can run at high speeds, so they reduce machining times. They resist oxidation and maintain hardness at elevated temperature, and are ideal for hard machining carbon steels, alloy steels, tool steels and cast irons.

Britta Teller and Evan Stover are the co-founders of Steller Floors, a sustainable hardwood floor startup based out of Tyrone. They are regular users of OriginLabs, Invent Penn State's prototyping and fabrication facility in State College. Credit: Provided by Britta Teller. All Rights Reserved.

Salah Taoufik, Kennametal’s global product manager for turning, said KY4300 tools have excellent high-temperature strength and hardness, and speeds can be increased 10 percent to 20 percent in most applications, compared with other ceramic grades, and produce results that include better surface finishes at lower cutting forces.

18581906093

18581906093