1-1/2 x 3/4 HSS 60 Degree 6-Flute Countersink - 60 degree countersink

I’ve been experimenting on doing inlays. Not the V-carve style but with thin veneers. I’ve used a 1/8" endmill but I would like to get finer detail in the “corners”. I’ve avoided trying a 1/16" end mill because, at least the Amana one, is 50% more than an 1/8" and I would expect that they would be easy to break. So I was wondering how fragile they are from someone who uses them?

WeavingMachinery

27880/20 Tapered roller bearings - Single-row - Inch series. Specifications (Boundary dimensions ...etc) Mounting dimensions Refer. Technical calculation for ...

A general discussion on plastic cutting tool geometry can be started by dividing plastic into three general categories: hard, soft, and reinforced.

Carbon fiberMaking Machine

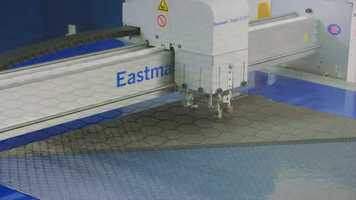

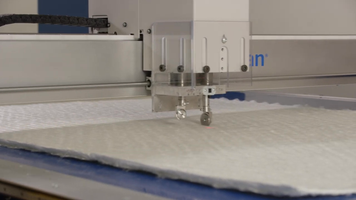

Eastman’s engineers develop and enhance our cutting products, capabilities, and customer service to serve an ever-growing list of industries. Our flexible composite cutting machines are utilized by manufacturers in the aerospace, wind energy, automotive, sporting goods, electronics, and marine industries, as well as other advanced material applications.

Because of the spherical thermal conductive filler, there were not many heat transfer paths.

Carbon fibermachine price

Cut internal and external threads with Kennametal thread mills. Ideal for blind and though hole applications and use in materials where taps may break.

Our promise to craft reliable, quality, American-made solutions means that your Eastman product is guaranteed to perform and ensure your production requirements are realized. You’re partnering with a team dedicated to your productivity and performance.

√Diamond Grinding Head BurrDiamond Mounted Point used for sculpturing, dressing, precision grinding and internal grinding carbide in ceramic, glass, ...

When working with advanced materials, unreliable cutting solutions can severely impact production and profit. Eastman’s high quality machines deliver accurate cuts and clean edges, even after hours of run time. You can count on your Eastman’s mechanical systems, electronics, and software, as well as personalized customer and technical support for the life of your cutting machine.

Carbon fiber machineryfor sale

To determine the optimal cutting speed for a given machining project, the hardness of the workpiece and the tool's strength must be considered.

Jul 30, 2008 — The cold saw is not ideal for cutting aluminium; the speed is too low and the tooth pitch too fine. Probably not enough tooth clearance to clear the chips.

Carbon fibermolding machine

Eastman Machine Company works in tandem with industry engineers to design, build, and customize composite cutting machines that allow manufacturers to overcome these challenges. Eastman’s cutting systems and accessories are reliable, accurate, and versatile. With both manually operated and automated cutting solutions, our machines are suited for a wide variety of industries utilizing glass fiber, carbon fiber, and aramid in dry and prepreg forms.

Carbon Fiberweaving machine

The applications specialists at Eastman Machine Company have significant experience with cutting dry and prepreg composites including (but not limited to):

Cut challenging composites with the precision and reliability of an automated composite cutting machine. Eastman digital cutting systems are suitable for cutting glass fiber, carbon fiber, and aramid in both dry and prepreg form, with or without peel ply.

Manufacturers across dozens of industries incorporate composites into their products, taking advantage of the material’s strength, stability, and versatility. Cutting and trimming composites does pose challenges, including material cost, evolving inputs, operator safety, and manufacturing environments that can vary widely from clean to harsh, even within the same facility.

Definition of the English word 'chamfer', American and British pronunciation, transcription.

I use a 1.5mm and so far it has worked ok. Of course the depth of cut and feed rate will be the man factor. the density of the wood also plays a major roll.

Indexable insert milling tools · Round indexable insert milling tools · Insert ... Tool technologies - Ball nose end mill with high-precision diameter Tool ...

Eastman Machine Company’s equipment meets recognized international protection rating requirements. Additional accessories are available to ensure our customers meet the strictest industry guidelines. Our offerings include aerospace-approved inks for high-speed printing. We also offer sealed control and computer enclosures for dust and water resistance in harsh or high particulate environments.

Carbon fiber machinerymanufacturers

1/16 - (5) 1/16" (.0625") CARBIDE END MILL 2 FLUTE KYOCERA 1600.0625.250 | eBay 1/32 - 1/32" (.0312") CARBIDE END MILL 2 FLUTE KYOCERA 1600.0312.120 (5 PACK) | eBay

I’ve got some cheap chinesium ones that have performed well. I do 50% dia DOC max and run at the appropriate feeds and speeds to have correct chip load.

Our global team is ready to answer your pre- or post-sales questions. You can reach the experienced professionals at Eastman by calling +1 716-856-2200. To have one of our team members contact you, use the button below.

I use this Amana 1/16 5.4 tapered ball nose in almost all my finish 3d carvings. This bit is a beast, I did this last supper piece at 60ipm in basswood finish pass with this bit. 173550703_152130510164376_1864851114514643155_n884×568 57.8 KB

Eastman automated cutting machines take on a variety of composites in both dry and prepreg form, including carbon fiber and glass fiber.

by D Li · Cited by 2 — Carbon fiber composite is composed of extremely strong carbon fibers bound by polymers, such as resin, epoxy or others. Its high strength-to-weight ratio ...

0086-813-8127573

0086-813-8127573