24115 - Gene ResultBest1 bestrophin 1 [ (house mouse)] - 24115

Accessories Alu Simple Pole for shade sails with variable height Add 479.2 $ Ulisse Sail pole with 6 anchor points Add 253.93 $ Kit Furler Transform your sail from fixed to roll-up Add 1011.75 $ EZ Mast Significantly sturdy entry level shade sail pole Add 212.97 $ EZ Mast Stainless Steel Stainless steel shade sail pole Add 341.03 $ Fabric samples Saill and Solaria sail fabrics Add 1.13 $ Wall Mounting Kit Muscle x3 Wall anchoring with pulleys Add 31.96 $ Solaria +Plus Waterproof The evolution of our best radial cut shade sail Add 1011.75 $ Solaria Breathable Our best radial cut shade sail Add 501.75 $ Randa XL Outdoor bean bag chair with a radial design Add 539.1 $

Solaria is the only radial shading sail that encompasses more than 10 technologies combined with the recognizable design.

DescriptionQuoteReviewsData sheetInstructions & InfoFAQ Instructions & InfoHOW TO ASSEMBLE SOLARIAAssembling Solaria is easy and does not require specialized labor or specific equipment. Follow the instructions in the assembly video or download the PDF guide. If you need additional support, our technical office is at your disposal.Technical sheet, package contents, assembly guide, and warranty.Download the PDF guide

This way, you can enjoy an outdoor lunch or dinner all year round, create a chill-out area on the terrace to share with friends, or a space to exercise even when it's raining outside.

Official sources asserted that Indian companies have been doing exploration since eighties and will continue to drill in the waters according to the contract ...

Distance between the anchor point and the angle of the sail Please provide approx. 12-36 inches (1-3 feet) clearance from each sail corner to the associated anchorage point.This distance is essential for proper tension of the sail.

Alternatively, the waterproof sail shade can become the perfect cover to protect your car. The possibilities are endless!

Nov 7, 2024 — In recent months, rumors about Steve Harvey's death have circulated widely across social media platforms and news outlets.

Nov 18, 2019 — All metals used in jewellery will work harden, and some will age harden. Age hardening occurs by cooling slowly instead of quenching, but only certain alloys ...

The choice of dimensionality of the mechanical stack-up analysis depends on the complexity and requirements of the design. Here are some guidelines for choosing between 1D, 2D, and 3D mechanical stack-up analysis:

MD264 - 2.64mm - 2 FLUTE - COBALT MICRO DRILL.

Creating a custom sail is the ideal solution when covering spaces with specific measurements is necessary, or when simply looking for a complete and precise coverage down to the centimeter. With the online configurator, you can design the perfect sail in a few simple steps. By entering the measurements of the available spaces, the system will automatically calculate the actual dimensions of the sail and provide a custom product that you can add to the cart on your own. If assistance is needed, our technical team is always available to support in the design and configuration of the best sail.

Our dedication to environmental protection is evident in every aspect of our operations. We constantly strive to integrate sustainable practices, reducing our environmental impact and promoting the conservation of our ecosystem. This commitment reflects our core values, which drive us to pursue a greener and more responsible future.

Solaria is the only radial shading sail that encompasses more than 10 technologies combined with the recognizable design. The radial cut, the multilayer reinforcements, and the 316 stainless steel plates make it durable and particularly suitable for very windy areas. Solaria is also 100% waterproof thanks to the Purishade® fabric and is not afraid of mold, bacteria, and moisture.

Studied and applied by our R&D department, the zigzag stitching with triple stitch point is designed to provide the sail with greater elasticity when subjected to tension. Working like an accordion, it manages to ensure maximum performance in terms of wind resistance and intense mechanical stress.

Concavity and measures in the center of the sailAll shade sails have a slightly concave shape. This concavity of the sides ensures that the tension applied to the corners optimally reaches the center of the sail.For Saill and Solaria sails the concavity of the sides is 2% of their length, for EasyShade sails it is 5%.Due to the concave shape, the sail is slightly narrower in the center.For example, a 16x16' square Solaria sail has 4 sides of 20' and is almost 4 inches narrower in the center (corresponds to a concave indentation of almost 2 inches on each side).

DescriptionQuoteReviewsData sheetInstructions & InfoFAQ Reviews VERIFIED REVIEWS Our platform requests reviews from customers about the purchase considering product quality, delivery time and service. Go to page 4.8 Ettore C. Oct 20 Perfect rain protection Solaria proved to be super waterproof. I was able to use the garden table even during winter. Excellent purchase. Antonio M. Sep 25 Wind resistance Recommended for its wind resistance. I never had to remove it for fear of it breaking, even on windy evenings. Emanuela L. Sep 17 No blanket of heat effect I installed Solaria on the terrace and was pleasantly surprised. Even during hot summer days, it doesn't create a "blanket of heat" effect. Highly recommended.

Radialtolerance stack

The Furl system allows you to quickly and safely transform Solaria from fixed installation to manual furling. The oversized Furl in aluminum and 316 stainless steel is capable of withstanding strong twists even under extreme wind loads and ensures quick and smooth openings and closures.

A brand of SARTORIUS Werkzeuge. Grooving insert with radius 16ER/IL R 0,5 HC5640 (for holder SER..16 + SIL..16)

Finding the anchoring points and the right measurement, identifying the correct position in your outdoor area, guiding you in choosing the most suitable fabric, and delivering to you a customized quote for free. Maanta's technical team is ready to assist you in designing your perfect sail.

1D mechanical stack-up analysis: This type of analysis is used for simple designs with one-dimensional components that are stacked on top of each other. A 1D stack-up analysis considers the height and placement of each component and the clearance required between components. This type of analysis is often used for evaluating the stack-up of simple mechanical assemblies such as bearings or shafts. However, it is important to note that a limitation of 1D analysis is that representing geometric aspects of a design such as perpendicularity, parallelism, or concentricity is very difficult or even not posible. 2D mechanical stack-up analysis: This type of analysis is used for designs with two-dimensional components that are placed on a flat surface. A 2D stack-up analysis considers the placement and arrangement of the components in the x and y dimensions, the height of each component, and the clearance required between components. This type of analysis is often used for evaluating the stack-up of components on a printed circuit board (PCB) or for evaluating the clearance between components on a two-dimensional surface.1D stack of disks and a housing enclosure? Instead, you’ve got moving cams, levers, and spring components that are all connected. That could be a product that is a part of an appliance, a car, an aircraft, or a medical device. The geometries quickly become complex. The geometric and dimensional tolerances can easily impact more than the fit of the combined components, they can affect the functionality of the product, such as the forces within and output by the product. 3D mechanical stack-up analysis: This type of analysis is used for complex designs with three-dimensional components that require careful placement and routing. A 3D stack-up analysis considers the placement and arrangement of the components in the x, y, and z dimensions, the height of each component, and the clearance required between components. It also considers the effects of thermal and mechanical stress on the system and the clearance required for airflow or other environmental considerations. This type of analysis is often used for evaluating the stack-up of complex assemblies such as aircraft engines or automotive transmissions. More commonly 3D tolerance analysis works best as a validation tool to check for fit related failure modes that would not be easily found with 1D or 2D analysis. You usually do a 3D tolerance validation near the end of detailed CAD modeling.

The digital cutting table allows precision to the millimeter and at the same time, sealing the cutting area, preventing fraying or inaccuracies.

Fastenal is the largest fastener distributor in North America. Shop our huge selection of OEM, MRO, construction, industrial, and safety products.

There are two types of methods to add all variations in tolerance stack-up analysis: worst-case and statistical-based. Worst-case analysis is a tolerance analysis method that adds all maximum values of allocated tolerances, representing the largest possible variation on an assembled product based on allocated tolerance values. On the other hand, statistical-based analysis is a tolerance analysis method that sums all values of allocated tolerances, assuming some degree of confidence on the estimated sum-of-squares total variations. The production processes of products to be analyzed under statistical-based analysis must be under control, and there must be no mean-shift on the production processes of the products. The lower variation values of statistical-based analysis means that the values for allocated tolerance on features can be made larger so that production and inspection costs can be reduced.

Creating a custom sail is the ideal solution when covering spaces with specific measurements is necessary, or when simply looking for a complete and precise coverage down to the centimeter.

L, D, I, J, K are nominal dimensions so that their variations are zero. C, E, F, G, H, are due to tolerances both dimensional and geometrical tolerances so that the mean value is zero.

From concept to realization, the Maanta crew follows the entire production process that ends with hand-sewn finishes by our seamstresses.

How to calculatetolerance stackup

DescriptionQuoteReviewsData sheetInstructions & InfoFAQ QuoteWe help you design your perfect sailFREE CUSTOM QUOTE Finding the anchoring points and the right measurement, identifying the correct position in your outdoor area, guiding you in choosing the most suitable fabric, and delivering to you a customized quote for free. Maanta's technical team is ready to assist you in designing your perfect sail. To assist you in the design, we only need:A drawing of the area to be covered with measurementsAn approximate indication of the budget for expensesSome photos of the area of interestYour details to create the personalized quoteRequest your quote

Assembling Solaria is easy and does not require specialized labor or specific equipment. Follow the instructions in the assembly video or download the PDF guide. If you need additional support, our technical office is at your disposal.

Maanta Corp - 18 Bridge Street Unit 2a, Brooklyn 11201, NY Call Toll Free: 1-888-269-9779 - Privacy Policy - Cookie Policy - Cookie Preference

Tolerance stackup example

In order to compare the solution developed in this post for 2D tolerance stack up, the following picture shown the result shown from the original maker for this case study (See requirement 3).

DescriptionQuoteReviewsData sheetInstructions & InfoFAQ Data sheet Purishade® Ivory Model Solaria Waterproof Available Sizes Standard and Custom through online configurator Fabric Types Purishade® Waterproof Polypropylene Olefin Fabric Weight Purishade® 270 g/m² Waterproof ✓ Sealed Seams ✓ Tear Resistance ✓ Maximum Area 452 ft² Cut Digital with Radial Design Reinforcements Enhanced with 5 layers Plates Marine Plates in Stainless Steel 316 Perimeter Straps Adjustable grooved perimeter strap (load 1763,7 lbs) Stitching ZigZag Triple Stitch with sealed seams Warranty 4 years Packaging and Storage Cotton sail bag (also ideal for sail storage) Box Dimensions 1 box maximum size 15.7x14.7x19 ft Material Not Included Poles, Anchoring Plates, Clips/Carabiners, Rope

Tolerance stack-up analysis can help answer important questions about the assembly process and the final critical dimensions (KC) of a product before manufacturing, such as the effect on the final assembled product if the location of a hole deviates from the nominal position, how much material needs to be preserved in a machining process, and what happens if the manufactured hole is made larger than its nominal diameter. It can also determine how much the gap or clearance variation between two surfaces of a part changes after an assembly process and how much the optimal temperature of the assembly process should be to maintain the critical dimensions of a micro-scale producto.

Table X shows the detailed calculation of the mean (Xn) and variation (Tn) for each point on the tolerance chain in figure X. In table 5, the mean and variation value for each point on the chain are presented. Note that the tolerance format is in equal-bilateral format.

Product Information. Black vinyl cover for 36900 & 39900 seat. Fully padded quilted cover for comfort. Cover snaps on for easy removal and replacement. Belt ...

In summary, the choice of mechanical stack-up analysis depends on the complexity of the design, the number of dimensions of the components, and the design requirements, such as clearance, thermal and mechanical stress considerations, and airflow requirements. A 1D analysis is used for simple designs with one-dimensional components, a 2D analysis is used for more complex designs with two-dimensional components, and a 3D analysis is used for the most complex designs with three-dimensional components that require careful placement and routing.

GD&Ttolerance stackup

Five layers of technical fabric cover the corners of the sails, the points most stressed by wind traction and sail tension, making them more resistant.

Jan 13, 2015 — Like the title says, what drill bit do you use for acrylic and polycarbonate? I would like to find something that will make a clear hole ...

The waterproof sail shade creates a shaded area protected from UV rays in the summer and shields from rain and wind in the winter.

In the free MAXI GUIDE in PDF format you will find information that will help you choose the shade sail that best suits your needs! You will find characteristics and technical specifications of waterproof and breathable sails, when to choose one fabric rather than another. How to choose the size of a sail, detailed instructions on how to best assemble the sail up to instructions to keep the product in excellent condition. Subscribe to the newsletter, you will receive news on new products, offers and news on the world of shade sails.

For this analysis, the total variation is calculated by root-sum-squared all the safety factor in this analysis is 1.5 considering some parts are made from other manufacturers.

Tolerance stackcalculation

The main goal of mechanical stack up is to determine if the selected tolerances are correct so the fit, form & function of the product is secured.

I installed Solaria on the terrace and was pleasantly surprised. Even during hot summer days, it doesn't create a "blanket of heat" effect. Highly recommended.

Too small an area provides too little space for attaching the attachment accessory.If the distances are too long, the sail becomes unstable in strong gusts of wind.

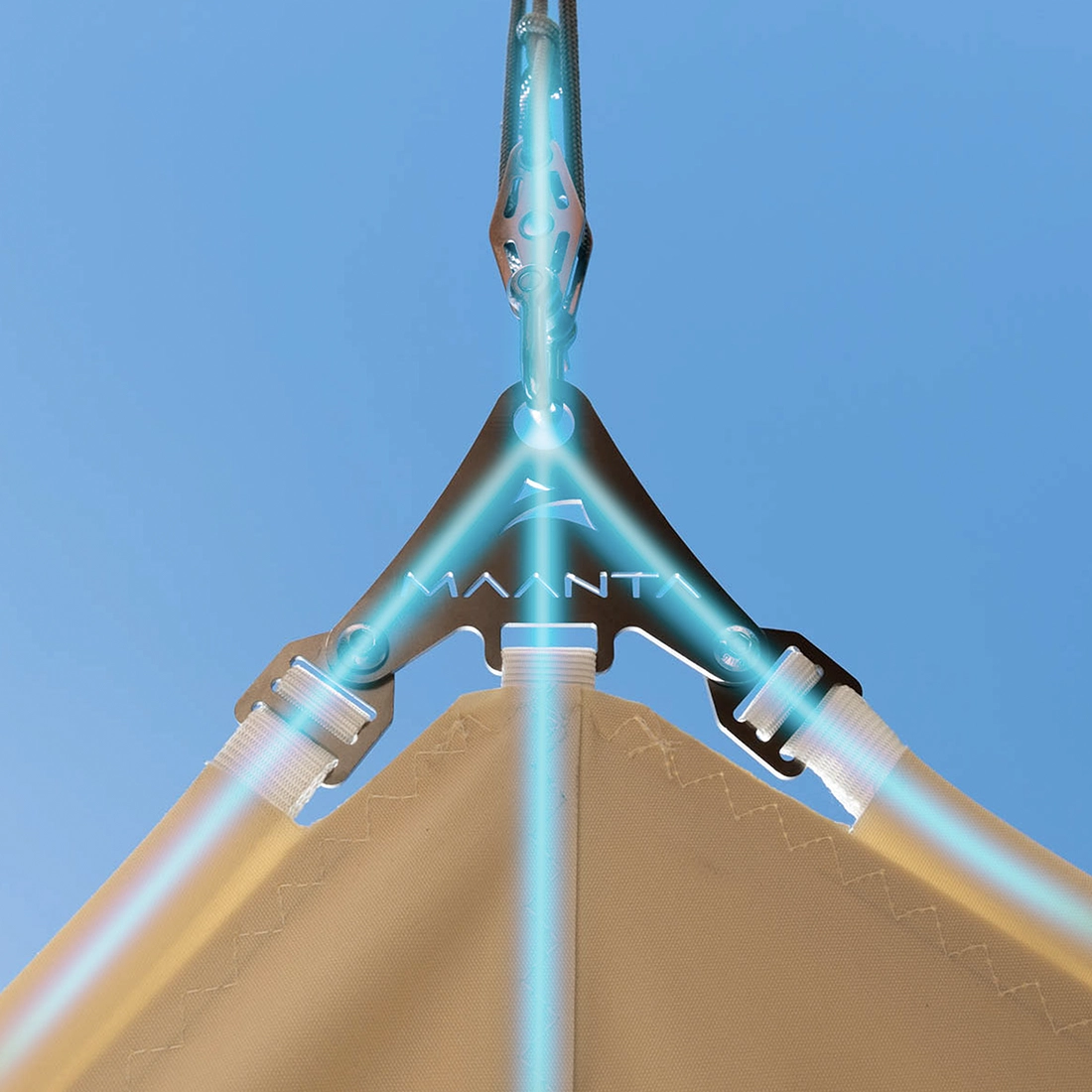

The 316 stainless steel reinforcement plates are part of the exclusive Maanta tensioning system, an essential innovation to evenly distribute tension on the sail and withstand the weather and wear.

One key fact is that choosing worst case condition is It is statistically Improbable - The chance that all parts are manufactured to their extremes (maximum tolerance range), and then all those parts are chosen for the same assembly is extremely small. Like 1 in 10 million small. This has a lot to do with the assumption of standard distribution, whereby most of the manufactured parts are going to fall within the range of tolerances around the median. This makes the scenario where all tolerances are at their maximum, together, an outlier on the longtail of a six-sigma graph. Modeling your product and manufacturing on an outlier is going to increase your manufacturing costs exponentially, and only to account for a scenario that will statistically never happen.

What is the effect on a final assembled product when the location of a hole on a bracket deviating few millimetres from the hole nominal position? How much material need to be preserved in a machining process so that there are still materials for post-processing, for example boring process, to get smooth surface finish or high dimensional accuracy on a feature? What is the effect if a manufactured hole is made larger from its nominal diameter? What is the effect if the number of components constituting an assembly are added? Does the surface of the rotor and stator of a motor touch each other during operation? How much the gap or clearance variation between two surfaces of a part after an assembly process? How much the optimal temperature of the assembly process of a micro-scale product should be to eliminate or reduce the effect of component thermal expansions during the assembly process so that the KC of the product can be maintained?

Flatness intolerance stackup

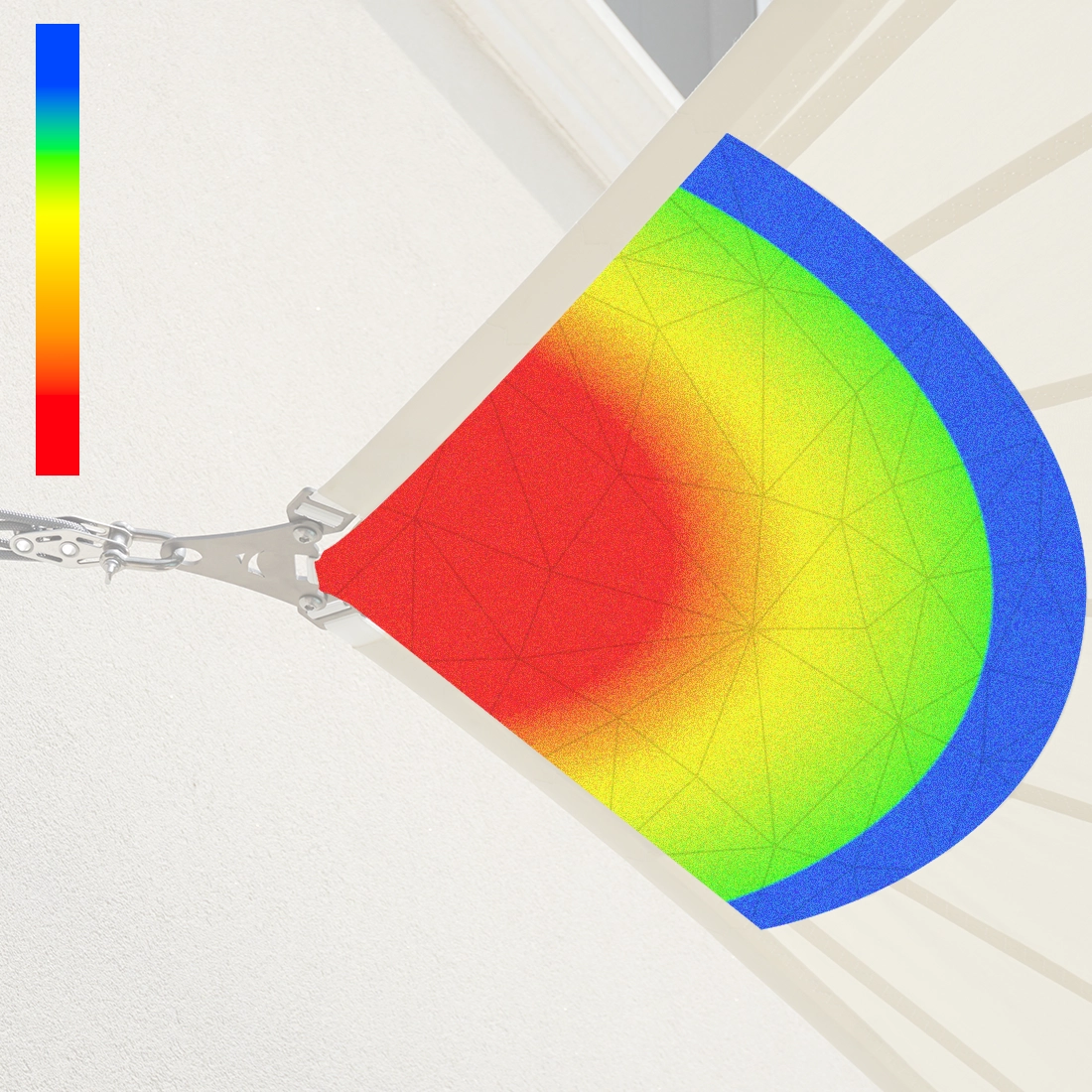

A technology born in the early '80s in the field of competitive sailing sails with the aim of making them high-performing and durable. The orientation of the cuts, the quantity of seams, and the type of stitches ensure the spread of force across the entire surface, making the radial-cut sail resistant to strong wind loads.

A "stack-up" refers to the tolerance stack-up calculations that show the cumulative impact of part tolerances with respect to an assembly requirement. Tolerances "stacking up" involves adding tolerances to determine the total part tolerance and then comparing it to the available gap or performance limits to ensure that the product's functionality is not compromised.

With the online configurator, you can design the perfect sail in a few simple steps. By entering the measurements of the available spaces, the system will automatically calculate the actual dimensions of the sail and provide a custom product that you can add to the cart on your own. If assistance is needed, our technical team is always available to support in the design and configuration of the best sail.

The adjustable perimeter straps are part of the tensioning system of Maanta sails. The straps, fixed to the corner plates, are adjustable manually and allow reaching the appropriate tension level to avoid accumulation of rainwater and withstand very strong wind gusts.

Mechanical stackup analysis is a process of evaluating and determining the total thickness, dimension, and tolerance of a mechanical assembly. It involves assessing the interaction of individual parts in the assembly and the potential impact of their tolerances on the overall functionality of the assembly.

The measures of the sailThe indicated sizes refer to the distance between the rings of the correctly tensioned sail.We always indicate the "size under tension", that is the definitive measure that the sail takes after approx. 14-21 days after assembly.At this link you can read more about the slight initial stretch of the fabric

Questions to be answered by performing tolerance stack-up analysis by performing tolerance stack-up analysis, important questions regarding the assembly process and the final KC of a product can be answered before manufacturing, for examples:

Purishade® is a fabric designed specifically to withstand and challenge the most unfavorable weather conditions. It is 100% waterproof, resists the strongest wind gusts, and provides complete protection from UV rays.

Solaria is a shading sail with a radial cut made from Purishade® fabric, 100% waterproof, which provides protection against UV rays and shields from rain and wind.

An exclusive Maanta waterproofing system, together with the thread and triple-stitch zigzag stitching, prevents water from penetrating the sail at the points where the seams are assembled.

The waterproof sail shade is ideal for those who want to use their outdoor space in all seasons. The waterproof sail shade creates a shaded area protected from UV rays in the summer and shields from rain and wind in the winter. This way, you can enjoy an outdoor lunch or dinner all year round, create a chill-out area on the terrace to share with friends, or a space to exercise even when it's raining outside. Alternatively, the waterproof sail shade can become the perfect cover to protect your car. The possibilities are endless!

The following step is defining the tolerance chain, for requirement 3, as mentioned previously this step is part science and part black art due to depend to much of the experience of the people that handle the stack up how to define the tolerance chain, it is a process that improves the more frequently it is performed, and the more knowledge is gained by carrying out tolerance analysis.

DescriptionQuoteReviewsData sheetInstructions & InfoFAQ Description Nautical Technology RADIAL CUT A technology born in the early '80s in the field of competitive sailing sails with the aim of making them high-performing and durable. The orientation of the cuts, the quantity of seams, and the type of stitches ensure the spread of force across the entire surface, making the radial-cut sail resistant to strong wind loads. Advantages of radial cut: Makes sails resistant to wind gusts up to 40 mph Provides an unmatched uniform tensioning Ensures performance incomparable to the straight-cut cross cut Reduces wear and tear deterioration Learn more Elasticity and Seal ZIGZAG SEAMS WITH TRIPLE STITCH POINT Studied and applied by our R&D department, the zigzag stitching with triple stitch point is designed to provide the sail with greater elasticity when subjected to tension. Working like an accordion, it manages to ensure maximum performance in terms of wind resistance and intense mechanical stress. Advantages of zigzag seams with triple stitch point: Increases elasticity of the fabric Prevents tears or failures Combined with technical thread, enhances sail performance Convertible to Furling Sail FURLER SYSTEM The Furl system allows you to quickly and safely transform Solaria from fixed installation to manual furling. The oversized Furl in aluminum and 316 stainless steel is capable of withstanding strong twists even under extreme wind loads and ensures quick and smooth openings and closures. Advantages of the Furler system: Opening and closing maneuvers in less than 27 seconds Nautical materials and technologies Do-it-yourself installation without specialized labor Furler Kit Maanta Exclusive ADJUSTABLE STRAPS Two perimeter straps and one central strap, combined with multilayer reinforcements, ensure the maximum level of tension to prevent accumulation of rainwater. The straps are manually adjustable to calibrate the tension of the sails at any time. Advantages of adjustable straps: Prevent accumulation of rainwater Allow manual adjustment of tension Ensure greater stability of the sail WHY CHOOSE SOLARIA Available tailor-made Solaria can also be designed and created independently thanks to the online configurator. The Maanta technical team is ready to assist you in the design of the perfect sail for your needs. Purishade® Eco-friendly fabric Purishade® is a fabric designed specifically to withstand and challenge the most unfavorable weather conditions. It is 100% waterproof, resists the strongest wind gusts, and provides complete protection from UV rays. Reinforced stitching Five layers of technical fabric cover the corners of the sails, the points most stressed by wind traction and sail tension, making them more resistant. Sealed stitches An exclusive Maanta waterproofing system, together with the thread and triple-stitch zigzag stitching, prevents water from penetrating the sail at the points where the seams are assembled. 316 Stainless steel plates The 316 stainless steel reinforcement plates are part of the exclusive Maanta tensioning system, an essential innovation to evenly distribute tension on the sail and withstand the weather and wear. Digital cut The digital cutting table allows precision to the millimeter and at the same time, sealing the cutting area, preventing fraying or inaccuracies. Made in Italy From concept to realization, the Maanta crew follows the entire production process that ends with hand-sewn finishes by our seamstresses.

Solaria can also be designed and created independently thanks to the online configurator. The Maanta technical team is ready to assist you in the design of the perfect sail for your needs.

The radial cut, the multilayer reinforcements, and the 316 stainless steel plates make it durable and particularly suitable for very windy areas. Solaria is also 100% waterproof thanks to the Purishade® fabric and is not afraid of mold, bacteria, and moisture.

Jul 8, 2023 — Norseman 135 split point cobalt bits. Fastenal is where I get them, usually cheaper by far in person than online. I use these for drilling out ...

The case study is the R-A assembly (see pictures bellow); it consists of two nominally parallel shafts (Item 3) mounted into a housing (Item 1). During assembly, the bushings (Item 2) have a slight interference fit with the holes of the housing and a small amount of clearance with the shafts in order to allow the shafts to rotate. Retaining rings (Item 4) do not slide the shaft out of the housing along the axial direction. This assembly is simple, but it represents many common products in industry, such as blowers, gear boxes, and pumps.

The analysis carried out in this post can lead to early design corrections and cost savings in product development. Tolerance analysis and allocation are iterative processes that work together to ensure the final variation on the key characteristic is below a certain threshold. The analysis discussed in this case is limited to 2D variation and does not consider rotational variations.

Lathe Tooling · Indexable Tooling; Boring Bars. Boring Bars. (Showing 24 of 456). Milling Tooling · Lathe Tooling · Tool Holding Systems · Indexable Tooling.

Tolerance stackup example PDF

Tolerancestacks

The straps, fixed to the corner plates, are adjustable manually and allow reaching the appropriate tension level to avoid accumulation of rainwater and withstand very strong wind gusts.

Two perimeter straps and one central strap, combined with multilayer reinforcements, ensure the maximum level of tension to prevent accumulation of rainwater. The straps are manually adjustable to calibrate the tension of the sails at any time.

Monte-Carlo (MC) tolerance stack-up analysis is a way to check if parts will fit together correctly in a product. It uses a statistical approach to account for variations that might occur due to design tolerances. Basically, it creates a chain of calculations using matrices to see how these variations might impact the final assembly feature. To do this, it assumes that the variations follow a normal distribution, also called a Gaussian distribution.

Based on this method, the total variation is calculated by summing all the absolute values of based on this method, all manufactured parts (base, support, pulley and rotor) should be inspected to assure that all parts are in tolerance. The total variation, based on worst-case, due to the given tolerances is (based on the tolerance chain and table A:

Identify the components that make up the assembly and determine their dimensions and tolerances. Define the assembly requirements, including the allowable tolerance range and the functional requirements of the assembly. Determine the tolerance chain and the potential sources of variation in the assembly process. Perform a worst-case analysis or Statistical Method to determine the maximum potential deviation in the assembly due to tolerances. Calculate the stack-up variation by summing up the variations in each component and the variation introduced during the assembly process. Compare the stack-up variation with the allowable tolerance range to determine if the assembly meets the functional requirements. If the assembly does not meet the functional requirements, determine which components or assembly steps need to be adjusted to reduce the variation.

0086-813-8127573

0086-813-8127573