3/4" Diameter Square End Weldon (4FGMI) - weldon flat

Cutting tool wear The edge of a cutting tool wears down during machining which impairs the ability to achieve the desired tolerances and consistent quality.

Types of tool wearpdf

B. Flank wear Smooth wear on the flank of the insert. Caused by mechanical abrasion which, similar to crater wear, occurs due to wear from hard particles.

Flankwear

Cutting forces The wear is strongly associated with the cutting forces that a cutting insert is subjected to, which are a result of the tool's design, the angle of the tool holder, the cutting speeds, the choice of material, vibrations etc. Actual cutting forces are thus impossible calculate.

Craterwear

The cause of tool wear can be divided into the following types, that individually or in combination, will inevitably require a tool change.

E. Plastic deformation Deformation at the edge. Caused by weakening of the cutting tool due to overheating, which reduces its resistance to external impact.

Causesof tool wear

C. Notch wear Streaked wear on the bottom of the edge. Caused by mechanical abrasion from harder workpieces which, in the same way as crater wear, occurs due to hard particle diffusion. If a larger notch occurs among the smaller ones, it is probably due to the surface deformation from a previous cuttin pass. The notches can also appear on the rake side of the insert.

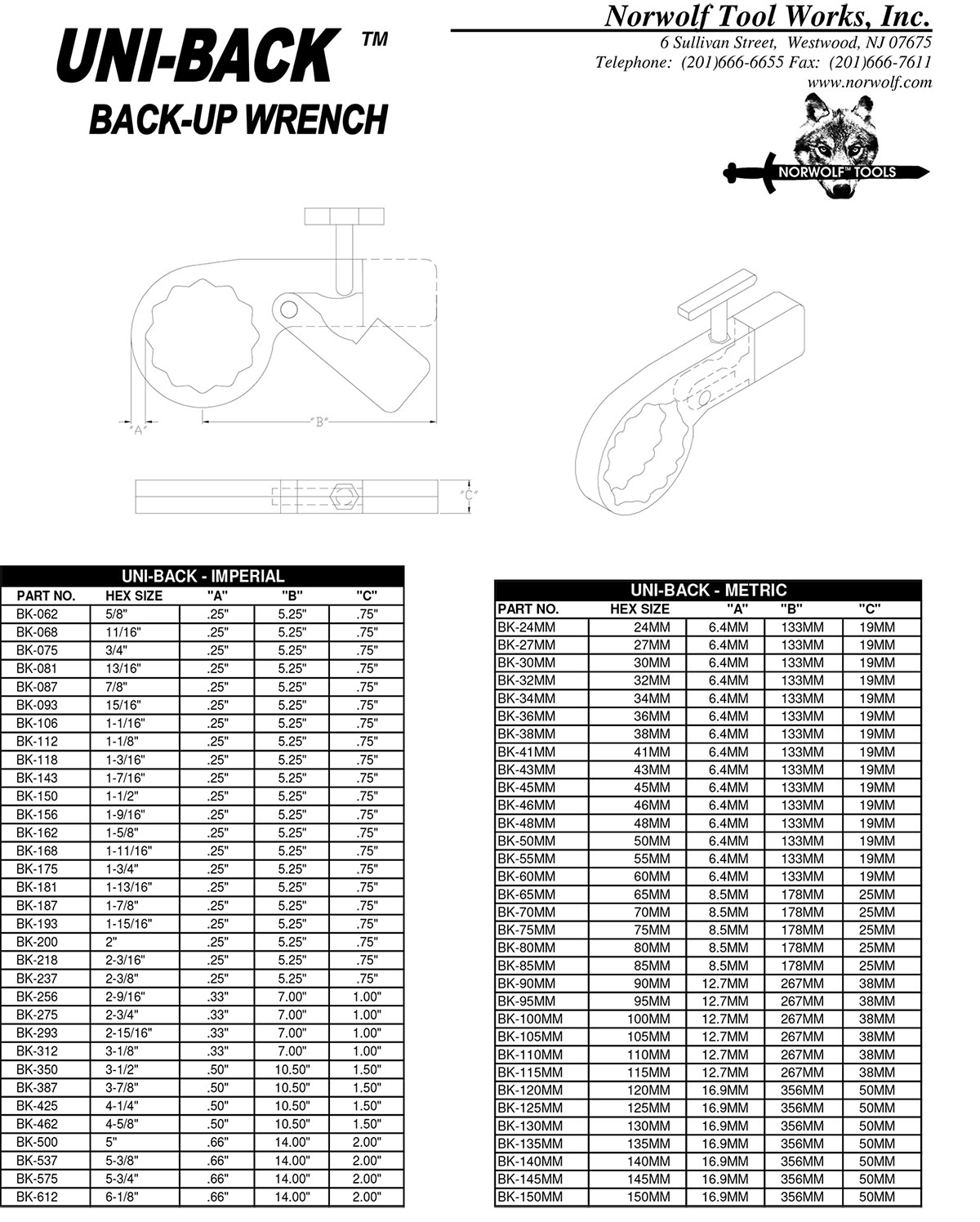

The effortless removal of this back up wrench increases the safety of your worksite, and makes your job much easier. Its thin profile and radius ensure that you are able to use it in low clearance places.

D. Comb cracks Small cracks across the edge. Caused by repeated thermal changes that cause the material to expand and contract, which leads to cracks and subsequent chipping.

A. Crater wear Crater-shaped wear on the cutting edge of the insert. Caused by mechanical abrasion when hard particles in the chip, eg oxides or carbides, meet the cutting surface. Diffusion between the material and the insert accelerates the formation of the crater wear.

The Uni Back hold back wrench will contribute to preventing injuries on your worksite. It replaces the use of a box end wrench when tightening fasteners, eliminating the need to remove a jammed wrench after your task is complete.

0086-813-8127573

0086-813-8127573