3/4" Diameter Square End Weldon (4FGMI) - weldon flat

Cast ironcutting speed

Each of the machining parameters is dependent on the selected material and its machining susceptibility. Among others – this is the reason why the cutting speed for steel machining will be different than the parameters recommended in the case of aluminum machining.

Cutting speedformula

These differences are easy to identify by experienced operators of machining devices.On the other hand – while using new tools, operators should closely observe the effectiveness of recommended parameters to choose the perfect one.

2005 – M.Sc. (Eng.) Informatics, Gdansk University of Technology, 1996 -1997 a captain of a finalist team in a ThinkQuest contest (Join Our English language Club), 1998 – 2003 a member of Distance Education Centre involved in EU projects (Leonardo da Vinci, Socrates,Comenius, Grundtvig, Minerva), July – August 2004 - an apprentice in Young Digital Planet, August 2007 – March 2009 - Compuware, a winforms C# developer, November 2009 - March 2011 - a web developer (C#, JavaScript, HTML, CSS, ASP, SQL 2008) in Agentrics, London, UK), January 2006 – August 2006, IdealHost - a C# webforms and HTML developer, July 2007 – a teacher in 4 days seminar about e-learning, HTML and use of IT technologies for postgraduate students at Higher School of Public administration in Szczecin, from October 2006 in PRO-MED sp.z o. o. - a web developer, Moodle and WordPress administrator.

I am a young scientist, researcher teacher and an engineer. I publish and do research on human system interaction and interface, eye tracking and hospital information system. For my research I was awarded with the prestiges scholarships (InterPhD twice and InnoDoktorant) for the PhD students. I was Previously associated with City University London (UK), Gdansk Medical University Hospital and OrlandoHelath Hostpital (FL USA).

CNC feed rate foraluminum

Cutting speedforAluminum6061

CNC operators early observe the whole machining process – that is why the selection of the right parameters is so important. On the other hand – the selection of said parameters is the responsibility of a professional CNC machining operator.

Cutting speed is one of the most important parameters of work of machining devices like lathes, mills, and others, designed for chip processing. Such parameters describe the speed of contact between material removal elements (like bits, blades, or cutters) and the material surface. Right cutting speed has a direct impact on tool longevity and the final effect of the machining surface.

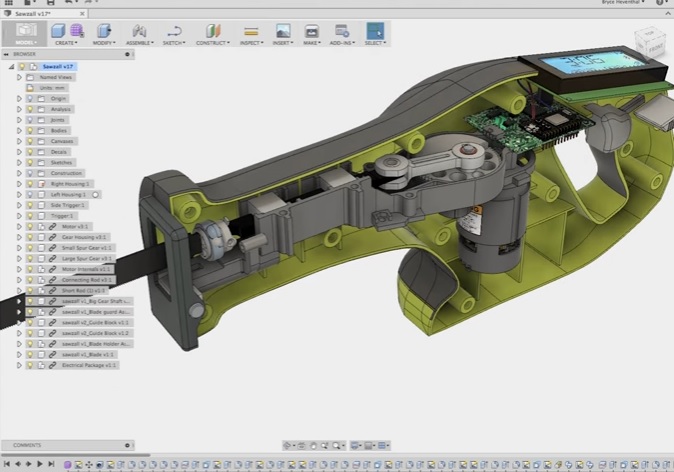

Fusion 360 enables exploration and iteration on product ideas and collaboration within distributed product development team.

The course materials are available under the Creative Commons licence - Attribution-NonCommercial-ShareAlike 4.0 International (CC BY-NC-SA 4.0), unless stated otherwise.

Aluminummillingspeedchart

EMMA provides a certificate to whom complete more than 70% of the course. These certificates are not credit bearing. You will receive your certificate directly via email a couple of weeks after the end of the course.

Contact us and tell us what you need. We have been providing CNC services for almost 40 years. Our valuation is completely free. And if you're in doubt about which technology will work best for you, our expertise is at your service.

Even when a tool manufacturer adds information about recommended Vc for a particular material, it is still good to know how to calculate that parameter – based on observation and knowledge. It is worth mentioning that there is a correlation between the hardness of the machined surface and the cutting speed value.

At RADMOT, we offer CNC milling services, CNC turning services, as well as many additional services, including washing, aluminum anodizing, laser marking and assembly. We have at your disposal over 80 modern machines in our machine park, all from renowned manufacturers. Download the presentation and check on which machine tools we produce CNC turned parts and CNC milled parts.

On top of the recommendation related to the bigger groups of material, there are differences between series or types of alloys. For example – milling aluminum of series 2xxx requires different parameters in the case of series 7xxx.

Each tool, even used within specification, can degrade in time – this is a completely natural process. But there are some things that can impact the tool's life – among many: cutting speed. Wrongly selected can cause numerous problems, among many – tool degradation and a decrease in the surface quality of the machined part.

Cutting speedforaluminumwith HSS

EMMA - University of Naples Federico IIVia Partenope, 36, 80121 Naples - ITALY info@europeanmoocs.eu - www.europeanmoocs.euTechnical Support #EUMOOCS

Autodesk, the Autodesk logo, Autodesk Learning Videos are registered trademarks or trademarks of Autodesk, Inc., and/or its subsidiaries and/or affiliates in the USA and/or other countries. All other brand names, product names, or trademarks belong to their respective holders. Autodesk reserves the right to alter product and services offerings, and specifications and pricing at any time without notice, and is not responsible for typographical or graphical errors that may appear in this document. © 2017 Autodesk, Inc. All rights reserved.”

Dr. Eng. Anna Grabowska has over 20 years of experience in distance education. In 1994 she received a master's degree at the University De Montfort in Leicester in the UK. In 2001 she defended her doctoral thesis with the title of a doctor of technical sciences at Gdansk University of Technology. Since 1995 she has been the manager of Autodesk Authorised Training Centre at Gdansk University of Technology (Authorised Academic Partner). In 1998-2004, she served as head of the Distance Education Centre at Gdansk University of Technology. She is a founding member of the Association of Academic E-learning, advisor at U3A online. Since 9 years she has been conducting meetings with the computer for seniors. She has been involved in several European projects dedicated to active aging (e.g. Learn with Grandma, Seniors Acting Together, ForAge, MATURE). Since 2014 she has been represented the company PRO-MED sp. o. o. in the project ERASMUS + SP4CE. She is responsible for designing and implementing a platform for communication and joint activities for students, teachers and companies.

Cutting speedfor brass on Lathe

The definition of cutting speed (Vc) is pretty simple: it is the movement speed (linear) of a machined surface with respect to a machined element. In other words – it is a measure of travel in time, described in meters per minute (or feet per minute).Machining speed is one of the key parameters of machining – the chip processing; on the other hand, remains important for the grinding process. In measurements and technical documentation that parameter is described as Vc (V = velocity; c = cutting). Such a parameter is often called 'cutting velocity', but this is not fully accurate (due to differences between these two). Cutting speed is often given by a cutting tool manufacturer (cutter, turning bit, etc.) in regard to typical materials with known machinability properties. Selection of the best possible cutting speed depends on the operator's awareness of aspects like:

Such a formula for cutting speed allows quick calculation of the cutting speed. On the other hand – it is a parameter that is often given by a tool manufacturer – most often in the form of range for particular types of material. Selection of the right cutting speed is still the responsibility of a machining operator. Based on their knowledge and experience, such specialists can calculate the right parameters for machined material, tools, and even particular machines and their possible tolerances. It is worth knowing the mentioned pattern, even if you can find it easily on the internet cutting speed calculators.

Cutting speedforaluminumwith carbide

The selection of the right cutting speed is important while working with automatic machining devices, but is even more significant when used in numerically controlled mills or lathes.

Eng. Ewa Kozlowska is a student of Mechanical-Medical Engineering, interacademic field of study run cooperatively by Gdansk University of Technology, Department of Mechanical Engineering and Medical University of Gdansk, Faculty of Medicine. Since April 2015, as a volunteer, she has been taking part in meetings with the computer for seniors at the Gdansk University of Technology. As a part of her apprenticeships in the PRO-MED sp. z o. o. company she takes part in the ERASMUS + SP4CE project. She is a certified Fusion 360 instructor at the Autodesk Authorised Training Centre at the Gdansk University of Technology.

This project has received funding from the European Union's Competitiveness and Innovation framework Programme under grant agreement no 621030

Cutting speed for mills requires the movement velocity of the outer surface of the spindle in relation to the shaped object. A similar description fits also grinders (speed is calculated based on the used tool). That parameter in lathes machining describes the distance in time of the machined surface in relation to the cutting bit. As you can see – outer surfaces of the objects (machined and tools) are very important.Their speed is a base to calculate the actual cutting speed. It is worth mentioning the parameter is strongly connected with the revolution speed–cutter on the spindle of the lathe head. Precise selection of that parameter has also an impact on the degradation of machining blades – too low or too high can cause faster tool degradation. It is similar to the usage of the wrong tools to work with particular types of material.

0086-813-8127573

0086-813-8127573