Carbon Fibre Drill and Countersink Kit - For M3 and M4 ... - drilling carbon fiber

Coffin Turbo Pump has realized a 35% to 40% reduction in machining time by CNC milling, threading, turning and grinding in their new SORALUCE TAM 25 multitasking machining center. The SORALUCE machining center is the single largest investment made in their plant in over 20 years.

This document contains the results of calculations for thread dimensions and strength based on a 0.5 inch nominal diameter screw with 10 threads per inch.

Dry carbon fibre is often considered a more premium option because of its superior strength and lighter weight compared to CFRP, but it also tends to be more ...

Long | XL | XXL Length End Mills · YG-1 · sku: E5H92008 · 1/8" Dia., 3/4" LOC, 4 Flute, Long Length, YGBasiX Carbide End Mill, Uncoated · YG-1 · sku: G9H92008N · 1/8" ...

Aug 28, 2018 — Peck drilling is typically used at CNC machines shops in Louviers, CO when the project requires drilling holes that are deeper than three and ...

Size Matters... That's why Select Machining Technologies has partnered with globally recognized brands of CNC machine tools designed and engineered for machining large, complex components, to bring advanced manufacturing solutions to American manufacturers' BIGGEST machining challenges.

Tri-V Tool and Manufacturing Co. doesn't turn down work or shy away from challenging parts. To meet customer demands, they’ve added more-sophisticated and advanced horizontal machining centers, an automated pallet system and multi-tasking part processing from Mazak. These updates help keep their shop competitive and profitable.

GEMINIS Large capacity, heavy-duty horizontal CNC turning solutions that are customizable for simple to complex applications.

We distribute this technology through our network of industry-leading full-service distributors; Morris, Hartwig, Gosiger, and Arizona CNC.

Great for cutting mild steel and stainless steel. Flange prevents over drilling. Split point pilot drill. Related Products. Carbide Tipped Steel Hole Cutter Kit ...

G-Wizard CNC Speeds and Feeds Calculator. The market leader used by 100000+ CNC'ers at thousands of leading manufacturers. Great for hobbyists too!

By combining advanced manufacturing technology with support from the industry's most knowledgeable and trusted distribution channel, we're ready to take on your Biggest, Tallest, Longest, Widest, Heaviest and most complex machining challenges.

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

The most powerful machine of its kind, the 6th generation IBARMIA Z Series moving column multitasking machining center is now Stronger, Faster and more Efficient for an even bigger ROI.

SORALUCE Advanced milling, boring, multitasking machines with automation for machining large complex workpieces efficiently with the utmost precision

Technology-driven leader of multitasking machines for large complex parts available with a wide variety of configurations.

CCMT 21.51 PF AH120 ; Cutting Edge Length (L), 0.256″, Max. Turning Feed (ft(max)), 0.0098 ″/rev ; Insert Thickness (S), 0.094″, Clearance Angle Major (AN), 7 ...

Enjoy this interview with Matt Sprogna, Director of Operations at FIBA Industries in Littleton, MA to learn how they've increased productivity on large storage vessels / tanks with the recent addition of a Soraluce FLP 14000 floor-type milling, boring, multitasking machining center

KBC,5/8 82 DEG. SINGLE FL. H.S. COUNTERSINK,1-159-810,KBC Tools & Machinery.

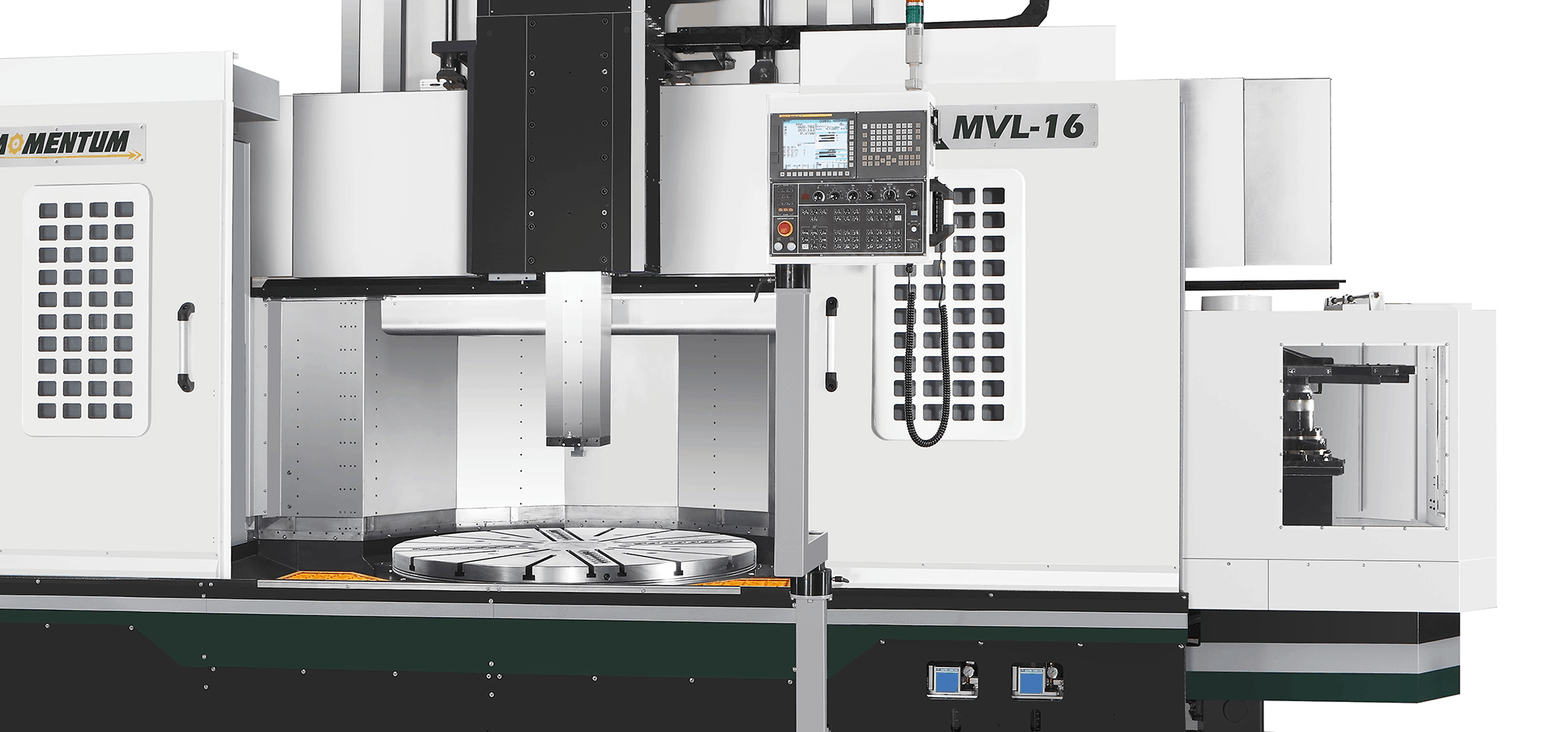

Here are some highlights of the advanced manufacturing technology demonstrated along the prestigious FRONT ROW of IMTS, by SELECT. The BIG machine line-up included a Soraluce SAD40 traveling column multitasking mill, a Geminis GT5i large-capacity multitasking lathe, an Ibarmia THC12 twin-pallet 5-axis universal multitasking machining centers and a Momentum MVL-15iM-SR vertical turning lathe with milling capabilities and the all-new Super Ram.

• 30% faster acceleration on the traveling column reducing cycle times • 10% faster tool changes reducing cycle times on complex parts • 20% increased workspace for machining larger components

“The Momentum MVL-16M lathe’s 63-inch chuck, 78-inch max turning diameter, and 63-inch max turning height gives Fabcorp the ability to perform full mill/turn work,” states Oscar Hernandez, Plant Manager at Fabcorp. “We've turned up to 3/8s, radial cuts on tough materials and have no complaints, the machine pushes it with the 75 horsepower main spindle.”

With a stay at Affittacamere Cá Leon in La Spezia, you'll be 2.2 mi (3.5 km) from Ferry Terminal and 7.5 mi (12 km) from Lerici Beach. This guesthouse is ...

We have solutions for your BIGGEST machining challenges. Reach out to our knowledgeable team today, so we can help find innovative ways to increase your shop's capacity and productivity

Upgrade your drilling game with toolant high-performance metal drill bits. Whether you're tackling regular metal or hardened steel, our cobalt drill bits ...

In this machine walkaround video, Doug Schulte, aka the Machine Tool Google, goes over the features of a Geminis GM9i Multi-Process Turning Center on the factory floor in Spain, before being shipped to a US based steel mill. Doug shares many of the design features that were developed specifically for the machinist, to provide easy, safe access to oversized parts being machined.

IBARMIA Machining technology with unparalleled performance, seamlessly integrating superior power, accuracy and reliability

0086-813-8127573

0086-813-8127573