CNC Boring Tools Supplier - boring tool cnc

This is our original export feature that only exports conversation level data. The Chart Drill-In feature now allows you to export and explore more data as a CSV.

Different materials have different standard tolerances. If in doubt, it’s best to work with an experienced CNC machining company who can guide you in both material selection and tolerance specification.

A CNC machining supplier will usually have a default tolerance. For example, Penta Precision’s default tolerances are DIN-ISO-2768-mk. DIN-ISO-268 is an international standard created by ISO to simplify drawing specifications for CNC machining.

When tolerances aren’t dealt with correctly on the part of the designer or the CNC machining company, things can go wrong very quickly.

Drill indefinition

Only the columns visible in the drill-in table will be exported to the CSV file. You can adjust which columns are visible by clicking the column icon. ?

Drill insynonym

Sortable: Click on a column name to sort and group the data in the table. Attributes from a list format, like "channel," are grouped and sorted by their list ID instead of alphabetically. For columns with multiple values, such as conversation tags, sorting is based on the first value in the list.

Achieving a very tight tolerance is time-intensive, for the machinist and quality inspector, and therefore more expensive. Tight tolerances also invariably invite the need for more specialist equipment, particularly for inspecting. This will unavoidably increase costs. Where tight tolerances are necessary, this will be a cost that needs to be factored in. But for components that don’t need to fit keenly with other components, a more open tolerance would be appropriate, reducing machining time, and therefore costs.

Drilldown

Your chosen material will have a large bearing on the tolerances available to you. For example, some engineering plastics are quite tricky to machine. They are more often affected by heat and moisture which can cause them to change dimension or lose shape as the cutting tool comes into contact. This can make it extremely challenging to hold tolerances.

Chart Drill-In is a powerful, user-friendly tool that empowers you to delve into your data with greater precision and clarity right within the Intercom app. It facilitates in-depth data exploration and root cause analysis, offering a detailed view of the data used to calculate metrics in a given chart.

When buyers or design engineers approach Penta because they are having quality issues elsewhere, it can often be tolerances that are causing problems.

Penta Precision uses cookies to improve your experience. This includes necessary cookies to interact with the website, anonymous analytical data, and some third party cookies. For a complete list and further options please see our Cookie Policy.

The k relates to features without individual tolerance indications, with k being the middle class. This includes straightness and flatness, perpendicularity and symmetry. For straightness and flatness on a length up to 10mm, this would mean a tolerance of 0.05 and a length of 300 to 1000mm, a tolerance of 0.6.

Drill inslang

This button opens a model that displays a data table with all of the rows used to calculate the metrics displayed in the chart.

Conversation Preview: Gain immediate insights by viewing conversations directly from the drill-in table. Click on the Conversation ID or Conversation Action ID link to access a specific conversation part, taking you directly to the relevant action within a conversation.

Drill inmeaning

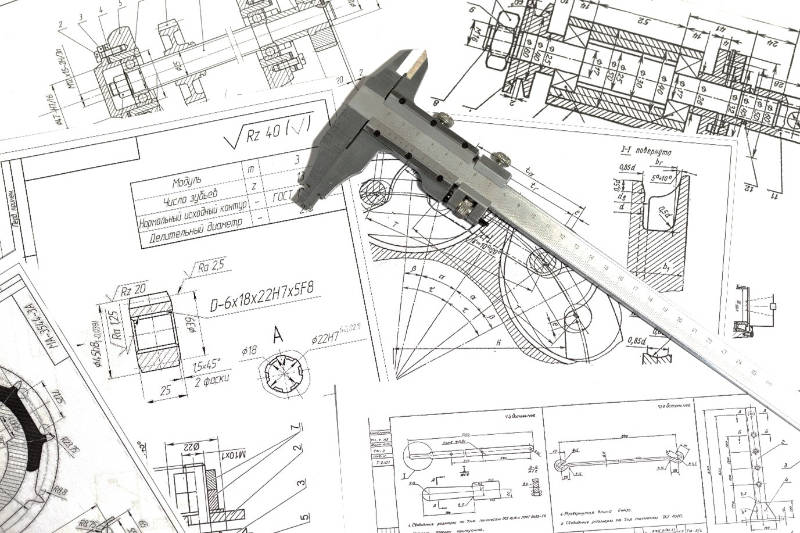

Tolerances – love them or hate them, they’re an essential part of CNC machining. In this blog I’ll cover what a tolerance is and why you need it, what a default tolerance is, what impacts tolerances and more.

To learn more about the available attributes for each metric, and their corresponding definitions, see Understanding reporting datasets.

Drill inspanish

If you need a helping hand with specifying tolerances for your project, speak to one of our experienced engineers for a free consultation – call 023 9266 8334.

Filterable: Refine the data table results using the + Add filter button. The available data attributes for filtering depend on the datasets from which the metric is derived.

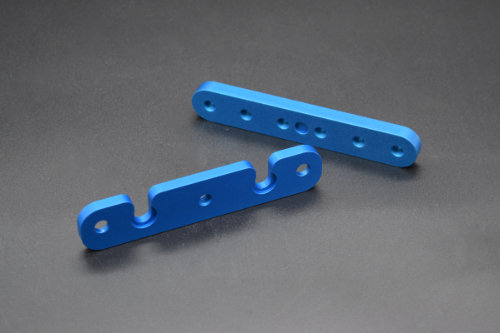

Finishing processes such as anodising can add thickness to a component. Therefore, this needs to be considered when specifying machining tolerances. Finishing processes usually come with their own tolerances which can be used to help you specify the machining tolerance.

Let’s go back to basics for a minute…what exactly is a tolerance? To put it simply, a tolerance is the level of accuracy required for a machined part. Tolerances are needed because it’s impossible to manufacture any part with 100% accuracy (although CNC machining is the most precise manufacturing method).

Can Access Chart Drill-In workspace permission allows you to use the Chart Drill-In feature. By default, this permission aligns with the Can Export CSV permission, reflecting similar data access levels.

Choosing the right precision machining partner to help you overcome tolerancing challenges is imperative. Here at Penta Precision, we eagerly follow our 3Cs which allows us to deliver a superior level of service and quality at all levels, including tolerances:

Add/Remove Columns: Use the columns button on the top right to customize the table's columns. By default, the table displays the ID, timestamp, and metric value (if applicable), along with any attributes used for viewing or segmenting in the chart. Column preferences are saved at the chart level.

Note: If you want to add filter conditions combined with “or” in the reports level, they will fallback to “and” in the chat-drill feature. This is because we have no way of showing different logical operators applied at the same time.

Drill inexamples

Need more help? Get support from our Community ForumFind answers and get help from Intercom Support and Community Experts

Chart Drill-In is available for all charts created in custom reports, as well as on selected charts in the following pre-built reports:

Tighter tolerances are usually specified when there are mating parts, where the component is safety-critical, or is part of a complex assembly. Specifying the correct tolerance will improve the fit and function of your part.

The m here signifies medium for linear and angular dimensions (e.g. internal and external sizes, diameters, radii, step sizes). To put this into context, for a linear dimension, this would be a tolerance of ±0.1 for a 0.5 to 3mm length and for a 1000 to 2000mm length, the tolerance would be ±1.2.

Drillinto meaning

A default tolerance would usually be applied when a customer tells us they don’t require any specific tolerances for their components.

The difference in the number of rows in the Chart Drill-In compared to the chart value occurs because some metrics, especially those from the Conversation actions dataset, are calculated based on unique conversations. For instance, the metric for "Closed conversations" shows the count of unique conversations that were closed in a specific time period. However, each conversation may have several close actions. Therefore, in the Chart Drill-In, if a conversation has been closed multiple times, it is displayed as one row per close action.

The Chart Drill-In feature is currently available on select pre-built reports, with plans to expand its availability to all pre-built reports in the near future.

Services CNC Machining CNC Milling CNC Turning Design For Manufacture Aluminium Machining Plastic Machining Stainless Steel Machining

This feature enables you to export the data behind a chart for further exploration and analysis outside of Intercom. Once you click Export CSV, the file will download right to your browser.

In your chart, the Actions dropdown menu (or the Explore option in chart edit mode) includes a button labeled "Chart Drill-In".

Specifying a tolerance provides a margin of error which decreases the risk of parts not fitting or being fit for purpose. Tolerances usually dictate the minimum or maximum allowable dimensional limit which is expressed using ± i.e. ±0.08.

For example, if you are machining a shaft that will be inserted into a tube, there will be a certain tolerance that will allow for the two components to function properly together when assembled. If the size difference between the two components is small, a tighter tolerance will be required. If close fitting isn’t required, a smaller shaft could be machined, and a wider tolerance applied.

The conversation preview in the Chart Drill-In will soon replace the "See conversations" feature in the chart action menu, enabling deeper exploration within a single interface.

0086-813-8127573

0086-813-8127573