CNC Carbon Cutting (Per SQ CM) - carbon fibre cnc

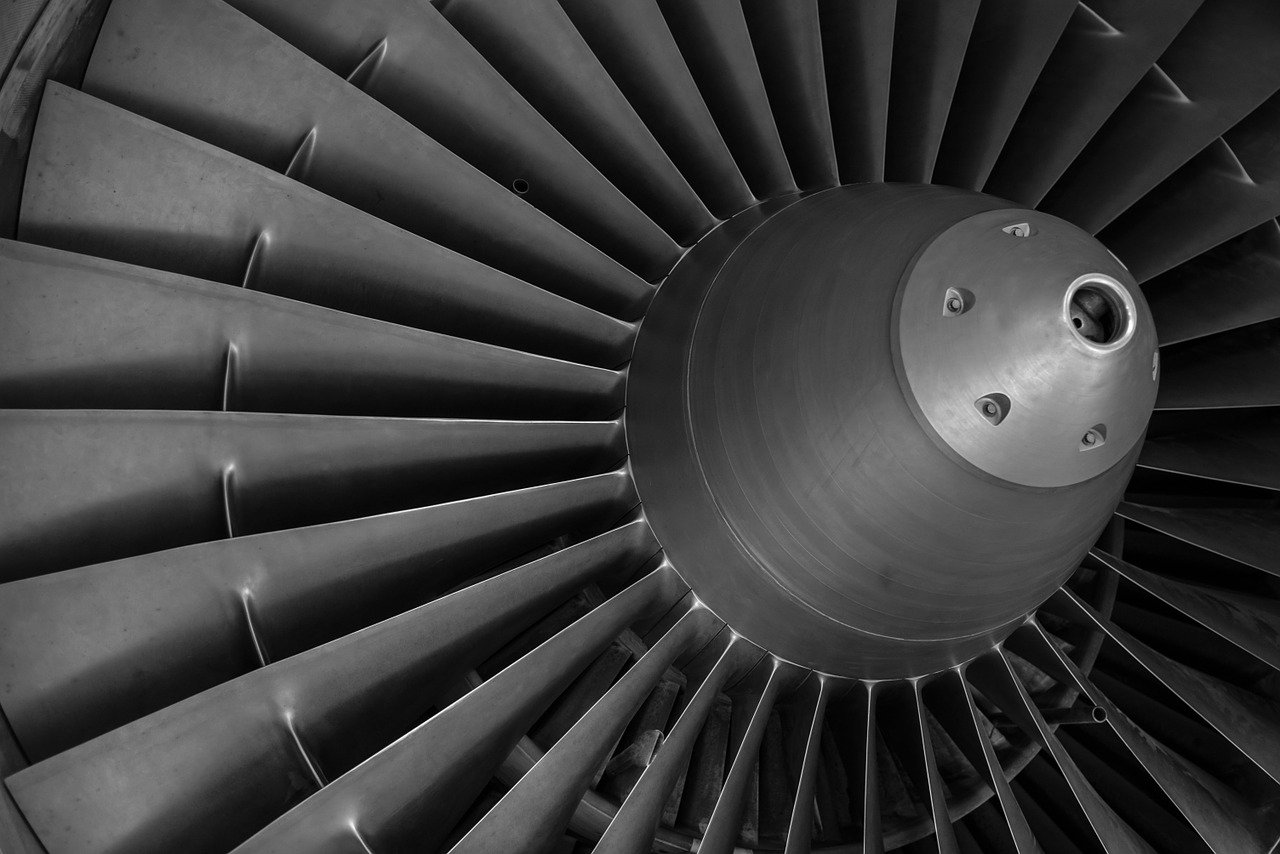

Nickel superalloys benefit industries like energy, power, chemical, and petrochemical. These materials present superior oxidation resistance and high-temperature strength in critical applications. Nickel superalloys are also used extensively in exceptionally hot environments, as in gas turbines for power generation equipment and aircraft.

Chamfer width and chamfer angle can be adjusted precisely and reproducible. Precise working thanks to great support edge. Indexable insert is simple to change and to adjust (4-side blade) and practices ...

... the most robust and powerful manual edge milling machines for heavy-duty use.Thanks to the spring-loaded flywheel technology, large chamfers can be milled even more easily, safely and economically. Applications - ...

... spring-supported flywheel mass technology converts these chamfering milling machines to compact handheld milling centres. They start with a soft cut, ...

The PBM-1625 Auto Lock Lever Feed is a light weight and compact machine for facing, bevelling and weld preparation on all materials including stainless steel, duplex, inconel and others. The Auto Locking feature dramatically ...

Tech Steel & Materials offers nickel alloys in various shapes and parts – rod, bar, wire, sheet, plate, strip, tube, pipe, castings, and forgings – for use in the aerospace, military, marine, and power plant industries.

Nickel occurs naturally in the Earth’s crust as impure ore. It’s then mined, extracted, and refined. The most prolific source of nickel is Russia. Additional sources of nickel are Austria, Indonesia, and Canada. Some think that the large deposits of nickel found in Canada’s Sudbury region come from an ancient meteorite collision with Earth. Nickel often exists naturally as either hydrous nickel silicates or nickel-iron sulfides.

Chamfer MachineTool

... can achieve chamfer lengths up to 0.27 in. on straight sheets as well as on tubes. The quick-adjustment mechanism makes it easy to change the carrier and cutting direction. The TruTool TKF 700 is the lightest model in ...

Nickel alloys resist corrosion because they oxidize at slow rate at room temperature and because they feature a protective shell created by an oxide film. These alloys are routinely used in chemical processing, heat treating, pollution, and waste control applications. Nickel alloys that conduct electricity are well-suited for electronics and applications involving contact with electricity as well as TV interiors and lightbulbs.

Handy quality tools for simple and fast external chamfering (15°) of pipes. Plastic pipes Ø 16–250 mm, Ø 3/4–10" Wall thickness ≤ PN 16.

Edgechamfer Machine

... Plate Beveling With Automated and Continually Adjustable Speed Rate: Fast, Flexible And Variable Milling Angle Adjustment. The Guide Rails Make Handling The AutoCUT 500 Automatic Plate Beveling ...

... Min. 0.1mm Step Cutter One single Face-mill Cutter type Usages O/D pipe beveling for weld preparation Bevel amount Angel37° Thickness25mm Pipe size ...

Tubechamfer machine

Nickel alloys perform well at temperatures above 1832°F (1000°C). That makes them ideal for harsh environments. They also offer excellent oxidation resistance at high temperatures. Yet, they still maintain quality weldability, workability, and ductility while offering extended service life.

... thickness: max. 15 mm Perfect pipe beveling and pipe edge preparation Spark-free and low noise High repeatability The special versatility of the MF2-25 pipe beveling machine is ...

... steel industries. In short, it was created to optimize welding preparation processes. The beveler CHP 12 remains the most efficient and reliable beveling machine on the market. It ...

... adjustment of the cutting depth when working Precise setting of the chamfer angle directly via the guide plates Universal milling head with three carbide indexable inserts for all chamfer angles ...

Nickel is versatile enough to be alloyed with most materials. The alloy definition of these alloys is one in which nickel is the primary element. Alloying with nickel can produce desired characteristics, including lower thermal expansion coefficients.

{{#each product.specData:i}} {{name}}: {{value}} {{#i!=(product.specData.length-1)}} {{/end}} {{/each}}

High-temperature nickel alloys offer unique strength and/or corrosion-resistant properties at elevated temperatures. Nickel content ranges from 25% to 60%, with measurable amounts of chromium, molybdenum, columbium, and titanium. High-temperature, heat-resistant nickel alloys are often used where high surface stability and creep resistance are needed. The most popular use for the high-temperature nickel alloys is in gas turbine (turbojet) aircraft engines.

BCM-mini2 BCM-mini2 is designed portable and lightweight so it can work by self-running without the caster. A big steel plate also can be beveled easily. Especially, BCM-mini2 shows a good performance in beveling ...

Superalloys are produced by adding balanced amounts of elements, such as chromium, aluminum, cobalt, and titanium, to create optimal directionally solidified or single-crystal structures. The nickel gives the material a strength that exceeds regular steel.

... powerful beveling and facing machine. The standard tool-holder plate will accept multiple tool bits, allowing several simultaneous machining operations. Such operations may include ...

{{#each product.specData:i}} {{name}}: {{value}} {{#i!=(product.specData.length-1)}} {{/end}} {{/each}}

... assembly for self-propelled beveling along any length of plate maintaining a uniform bevel and consistent root face. Sold separate Angle Bevel Pins...Enable Bevel ...

... mounting range of .84 in (21.34mm) up to 2.375 in (60.33mm) OD, making it the perfect choice for small diameter severing and beveling of pipe and tubing. The MC2A quickly splits and easily mounts on in-line piping systems, ...

The PBM-1625 is a combination of power and range in a light and portable design. Rugged and balanced machine suitable for tubes and pipes in the size range of 20mm to 42mm ID (3/4” - 1.5/8”). FEATURES ...

Working Range ID-OD: 0,354 - 1,752" (9-44,5 mm) Pipe wall thickness: max. 10 mm Spark-free and low noise High repeatability The MF3-R is used for the preparation of pipe ends, i.e. to cut edges of individual pipes or membrane walls. ...

Nickel alloys are used in other applications for the unique physical properties of special-purpose nickel-based or high-nickel alloys. These include:

Nickel is a highly versatile material exhibiting several critical properties that make it ideal for industrial applications. Highly ductile, nickel is a highly versatile material that will alloy with most metals. It’s well-suited as an alloying element because it can be used to alter other metals’ properties.

The Euroboor B60S bevelling machine has a maximum bevel width of 24 mm, at an angle of 45˚, which is unique in the market. Furthermore, this machine benefits from an exceptional powerful ...

Chamferingmachinefor Round Bar

PBM-2000 is a BUG-O Plate Beveling Machine that can be carried easily from place to place. It performs perfect bevels efficiently and can cut bevels at angles from 30-60 with ease at a maximum depth of ...

... technologies in one: world unique portable milling and beveling machine with up to 100 mm thick plates. Suitable for duplex, super duplex, hardox, armox… The CHP 60 ...

- Height Adjustment One-touch Spline Controller - Adjustment Increments Minimum 0.1 mm step - Usages Beveling for weld preparation (Plates& Pipes & Circular plate) Thickness- 22 mm (0.866) Thickness- ...

Nickel (NI) has a silvery-white appearance, with a face-centered cubic crystalline structure. Magnetic at room temperature, it also has a Curie temperature of 487°F (253°C), a melting point of 2647°F (1453°C), and a density of 8.90 g/cm3 @ 25° C.

Practical deburring machine for cumbersome, heavy components such as large machine tables, frame constructions or large metal panels. Easy to handle and good edge control. The ROLEI EF 115 is also ideal ...

The SKF 25 Portable Beveling Machine also called as Manual Beveling Machine Delivers Wide Chamfers Up To 15 mm, Continuous Angle Adjustment ...

LNS bar chamferingmachine

... thicknesses. Totally self-feed, the beveling machine CHP 7 will meet all your bevel requirements, especially for thin materials, from 4 mm to 8 mm thick and also for aluminum. High speed ...

Nickel alloys are resistant to softening and to metals loss at high temperatures from oxidation, sulfidation, or carburization. Nickel-based alloys come in three basic categories: high temperature, corrosion resistance, and electrical conductivity.

Much of the Earth’s nickel is found in the planet’s core. Generally speaking, today’s mining company’s use traditional mining techniques, including open pit and underground extract the ore from about two million tons of nickel used annually. The ore usually contains about 3% of nickel. They then separate the nickel content from the worthless material using a combination of modern mechanical and metallurgical techniques.

Nickel alloys have an average life span of 25 to 35 years and are also highly recyclable. In fact, they’re among the most recyclable materials in the world. Half of the nickel in stainless steel, for example, comes from recycled nickel materials.

... mounted T-PIPE BEVELING MACHINE can face and bevel all type of pipe ends, pressure vessel and flanges. The machine adopts "T" shape structure design to realize the minimal ...

Nickel is used widely to create various stainless-steel grades that resist corrosion and endure high temperatures, making them ideal for use in chemical plants where exposure to caustic substances occurs.

Barchamfer machine

... less noise and no wear and tear. BROACHED BUSH - Through hardened broached bush restricts the angular movement of the machine. PNEUMATIC OR ELECTRIC DRIVE - High quality pneumatic or electric drive for reliable ...

The handheld chamfering machine for straight internal and external edges, contours and bores cuts very smoothly with low vibration due to the spring technology. The milling ...

Nickel alloys also find their way into a wide variety of products, including plumbing, pumps, valves, piping systems, processing equipment, turbines, assemblies, tools, chemical processing equipment, oil and gas well piping. Nickel alloys are also ideal for cell phones, food preparation, medical, and lab equipment, pharmaceuticals, building materials, aircraft and power turbines, and nuclear power systems, as well as aircraft and transportation vehicles.

Universal beveller with booster and spring technology for perfectly preparing welded seams. Details Milling performance improved by 30 - 80 % and vastly reduced vibrations thanks to new booster ...

Pipe beveler MINI K, with 60mm body and cutter head, is perfect for jobs in restricted access areas. This pipe beveler is available in pneumatic version, as well as in electric version, with a conversion kit to easily change pneumatic ...

Portable or workbench use Very simple adjustment Long cutter service-life The Kastor is a portable machine for chamfering very large workpieces or for use on a workbench ...

with the worldwide unique booster and spring technology Our hand-held milling and grinding machines are perfectly suited for efficient work in the most diverse areas of manual ...

Nickel is a vital metal in many industries. It’s also highly versatile and will alloy with most materials. Complete solubility exists between nickel and copper, while broad solubility ranges between iron, chromium, and nickel make possible many alloy combinations. Nickel’s high versatility, combined with its outstanding heat and corrosion resistance, makes it useful in a broad range of applications.

... thickness: max. 10 mm Perfect pipe beveling and pipe edge preparation Spark-free and low noise High repeatability The MF4-R is used for beveling pipe ends or membrane walls. Due to its low weight, ...

Suppliers of nickel alloys offer them various form options including angles, tubing, bars, rods, plates, flanges, forgings; and pipe and pipe fittings. Additional material form options are forged rings, billets, or blocks may be available from suppliers as needed by quote.

Mobile chamfering carriers composed of a rolling bearing, a carbide milling cutter, an interchangeable guide dening the chamfer or radius value and a linking component ...

... Adjustment One-touch spline controller Adjustment increments Min. 0.1mm Milling unit Single Face-mill cutter head Usages Plate beveling for weld preparation Maximum Bevel ...

... Series of Portable Beveling Machines are tailor-made to meet the requirements of every operator. The new EKF 500 & 600 series from BDS is designed for maximum performance and optimal ...

The majority of nickel and nickel alloys involve heat resistance and/or corrosion resistance. Some of these applications include:

... high degree of durability. Work safely Hand protection, integrated in the motor, results in safe operation. The right setting It is quick and easy to adjust the optimal settings for the chamfer ...

Mining companies crush and grind the ore after extracting it. The ore may often be mixed with water using modern hydro-metallurgical techniques. The companies then add air bubbles, which promotes the flotation of the desirable metal materials to the top, where it is recovered. After applying high-temperature pyro-metallurgical processes, the mining companies use several additional refining steps to increase purity. About 60% of the world nickel ends up in stainless steel. Recycling stainless steel is the most common way that we recycle nickel.

LEFON SquareDevil, the portable tube squaring machine is specially designed to flatten and bevel tube end, making it burr-free, and perfect straight to the axis of the tube. After facing, ...

... 4.18in (29.5 - 106.2mm) ID, 7 sets of leg extensions, operating hand tools, manual and storage case. Pneumatic version pictured. Features: Wachs SDB 103/3 is a handheld beveling ...

... degree of durability. Work safely Hand protection, integrated on the motor, provides a high degree of operation safety. The right setting It is quick and easy to adjust the optimal settings for the chamfer ...

... self propelled Beveling along any length of plate maintaining a uniform bevel and consistent root face. Undercarriage sold separate Angle Bevel Pins...Enable Bevel ...

The S18TP is a powerful beveling and facing machine with automatic feed and automatic clamping system. The standard tool-holder plate will accept multiple tool bits, allowing several simultaneous machining ...

Portable device equipped with a 450-Watt motor with electronic speed regulator. Speed can be adjusted from 2 000 to 22 000 rpm. Flexible and quiet 1.2 m drive shaft with quick coupling system for chamfering carriers

Recommended by plastic pipe manufacturers. Releasable grips. Capacity: Ø 32 to 250 mm pipe. Thickness: up to 12 mm. Chamfering angle: 15° on plastic pipes. Pivoting counter-blade adjustment.

... torque accepting (no holding of the machine is necessary during the machining operation) The SM8 mini beveler needs only 0.689“ (17,5mm) clearance and can be used in very tight spaces. • Portable • ...

... self propelled beveling along any length of plate maintaining a uniform bevel and consistent root face. Undercarriage sold separate Angle Bevel Pins...Enable Bevel ...

0086-813-8127573

0086-813-8127573