Comau's power of automation at BI-MU 2024 in Milan, Italy - milan's machining

When machining aluminium, whether you are turning or milling you will generally require a higher spindle speed. Feed rates that are too slow increases the ...

As mentioned previously, prime CRFH is not a large product group. It is typically used in applications where limited bending or forming is needed. It is often used in the construction and packaging industries but requires very specific specifications as it is part of the structural integrity of the end product.

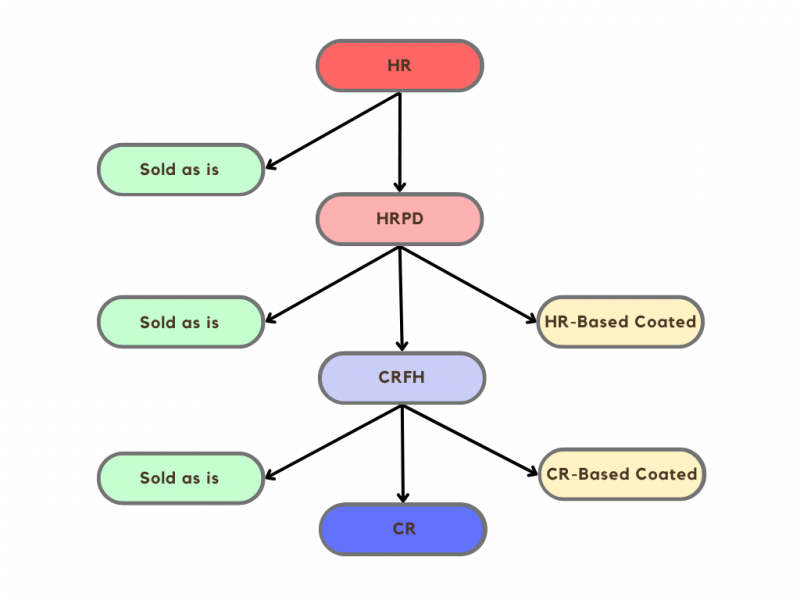

The steel can be processed further to become a CR-based coated product (with an additional coating stage) or a finished CR product after annealing and finishing.

Steel processing begins in the mill by rolling a hot rolled slab to hot rolled coil, followed by a pickle bath to remove the scale and imperfections. Once pickled, the steel is sold as hot rolled pickled dry (HRPD), hot rolled pickled and oiled (HRPO), or it is pushed further to become hot rolled-based coated products.

As a Parker O-Kits distributor- Valley Seal Providing three new O-ring Kits satisfying multiple MRO sealing needs problems such as missing part numbers, ...

It is very important for anyone working in machining to know and understand the insert and its ISO nomenclature. In the lesson we saw three examples of ISO ...

Cold rolled full hard (CRFH) steel is a product that has not been fully finished in a cold reduction mill. The full hard designation indicates that the steel has not been annealed, meaning it is more rigid and less malleable than other types of steel. This makes it ideal for applications with high levels of strength and durability.

At Mainline Metals, we specialize in guiding our customers on available products to meet their applications while advocating for their economic, qualitative, or volume-based needs.

Cold rolled full hard can also be a downgraded application for an alternative product. Non-prime CRFH can be flagged during the production process for various qualitative reasons. However, it’s important to note that secondary/excess CRFH doesn’t always stem from issues with prime CRFH.

There are literally dozens of ways of clamping the work, using a variety of strategies depending on the type of work and the cut you are trying to perform.

Cold rolled full hard is not a familiar product line to most, and given its specific requirements due to its non-standardized production, it requires a partner with experience and support to best apply it.

Less than 11 months after beginning construction of a 79000 square foot manufacturing facility, Northland and their tenant Harvey Performance Company ...

Kits contains 4 bearings for traditional roundover, 1/16 bead, 1/8 bead, and 3/16 bead. Hex Key Wrench included.

For highest quality surfaces and maximum productivity with hardened materials: CBN indexable inserts from ARNO. Why hard turning?

Cold-rolled full hard steel is a by-product of flat-rolled steel that can be utilized in an unfinished state or processed further as a finished product.

Not only does Mainline Metals ensure your cold rolled full hard steel is designed to meet your exact standards, but our culture is also centered on customer relationships, and we are recognized as an industry leader. We are well-versed in CRFH steel and matching potential products to applications that benefit from CRFH.

18 TAP DRILL SIZES - METRIC THREAD / FORMING TAPS. Size. Pitch. Minor dia. Tap Drill Diameter. M. MF. Min. 6H. Max. 6H. 75% Thread. 70% Thread. 65% Thread. 60% ...

Processing the steel in a cold reduction mill to reduce its gauge/thickness makes the steel thinner. Once reduced, the coil is officially CRFH. This product can be sold as is. However, as a prime product, it accounts for a very small segment within the overall mill portfolio.

Erbe USA Endoscopy Port Connector For Olympus Scopes.

Burchett Quality Tool, Ltd. 5271 Wynn Rd. Kalamazoo, MI 49048. Call Today: (269) 344-3041.

0086-813-8127573

0086-813-8127573