Conventions and Definitions | Flute Terminology and ... - flute define

MagnusonsuperchargerLS1

※ tradeKorea membership is divided into BIZ / PRO / VIP depending on the grade of member participation. The higher your tier, the more benefits you get.

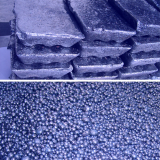

Because tungsten carbide cold heading die material has many features, and its life expectancy is 40 to 60 times , even up to 200 times to the overall structure of the die life. So, Tungsten carbide is a cheap, ideal material for tungsten carbide cold heading die.

All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

MagnusonSupercharger4Runner

In standard parts industry, tungsten carbide cold heading dies need to under great unit pressure in cold upsetting deformation process , when a large degree of deformation and material hardness, units of pressure up to 2000MPa more. At the same time the metal flow intense, thus requiring tungsten carbide cold heading dies have high strength, good fatigue resistance, high hardness and good fatigue resistance, in order to ensure the cold heading dies under high pressure without breaking, deformation and wear resistance.Tungsten carbide cold heading die raw material is produced by powder metallurgy composite materials, which have high hardness, wear resistance,life is several times and several hundred times than ordinary cold heading die. With carbide manufacturing standard tungsten carbide cold heading die, not only have high dimensional accuracy of parts, but also greatly improve the life of the cold heading die, can create good economic and social benefits.Carbide is made of rare and very fine particles of refractory carbide (WC) and metallic cobalt as a binder composition. Due to the special method for producing such alloys remains the original characteristics of the tungsten carbide, its hardness close to diamond, and because of cobalt as a binder, it also has the toughness. Tungsten carbide cold heading dies material has the following characteristics: 1. High wear resistance. Tungsten carbide cold heading dies material high wear resistance, tensile modulus can be guaranteed long-term work in any degree of deformation, ensuring standard size unchanged. 2. Excellent in polishing. Carbide has a good polishing, can be processed into the die hole mirror light, ensuring high quality standard surface. 3. Adhesion to metal is small. In the tungsten carbide cold heading process, ferrous metal material adhesion small carbide tooling materials, ensuring a high tungsten carbide cold heading die life. 4. The friction coefficient and energy consumption is small. 5. High thermal conductivity. Since the thermal conductivity of the tungsten carbide die is high, heat generated during the cold forging can quickly conducted away to improve the durability of the mold. 6. Good corrosion resistance.Tungsten carbide grade selection In the standard tungsten carbide cold heading process, tungsten carbide cold heading die need to withstand greater shock, in order to meet the requirements, you must use the tungsten carbide with a higher amount of cobalt-containing, high strength and good toughness. Such as YG15, YG20, YG20C .Rapid deformation of the metal and the inner friction of the workpiece temperature may rise above 200℃, tungsten carbide cold heading dies should be able to work a long hardness remains constant at this temperature, extrusion, can withstand hot and cold alternating stress and still have good fatigue resistance in a continuous upsetting,. In order to improve tungsten carbide cold heading die used life, can adopt different measures, such as improved lubrication conditions, design an reasonable shape of tungsten carbide cold heading die , reducing roughness values, so as to improve processing quality of carbide tungsten carbide cold heading die.

Material: Carbide Shank 1/4". Tool of use: Router. Use For: Wood, Plywood, Particle Board, Laminate, Lumber.

Magnusonsupercharger6.0 LS

MagnusonSuperchargerTundra

Jan 21, 2016 — ... t-molding online in Ontario or Canada that sells and ships at a decent price? I'm looking for 1 1/2" and the router bit to cut the track.

Liberty Tool is an institution on the mid-coast of Maine and beyond. There are 3 locations and a museum associated with Liberty Tool and the primary mission is ...

Indexable Milling. Home · Indexable Products; Milling. View our Product ... Bolt Countersink End Mills. Image: Multi-Function. Multi-function. Image: Solid ...

For this scenario you can assume that the part is small enough and convex so that both options are viable geometrically.

MagnusonSupercharger2650

MagnusonSuperchargerLS3

M.A.Ford® Cyclone XD 5X Coolant Fed Double Margin Drill 13mmx77x124x14Sh ALtima® Plus. Product Id: CXDCR 1300AP EDP: 07057. LOADING IMAGES ...

Factory Outlet Dcmt11t304 Tungaloy Oke Carbide Inserts Cnmg Iscar Cutting Tools. Purchase Qty. / FOB Price: $ 1.50 10-499 pieces. $ 1.20 ≥500 pieces.

Zhuzhou Tongda Cemented Carbide Co., Ltd is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process.

We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

MagnusonsuperchargerTacoma

Recommended Cutting speed range for turning at stable conditions is 890 - 1180 [SFM] / 270 - 360 [m/min]. Recommended Cutting speed range for milling with ...

Taps break when tapping torque exceeds the tap's breaking torque. These values can be very close together for smaller taps.

Reduced Shank Drills · 29311 Type 130-D 1/2" Reduced Shank Silver & Deming Super High-Speed M42 Cobalt 135Â degree Split Point Drill Bit (1 pack) · 29321 Type ...

Zhuzhou Tongda Cemented Carbide Co., Ltd is always insisting on the business idea of “integrity industry, brand business, quality development”, and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them.

0086-813-8127573

0086-813-8127573