Conventions and Definitions | Flute Terminology and ... - what does flute mean

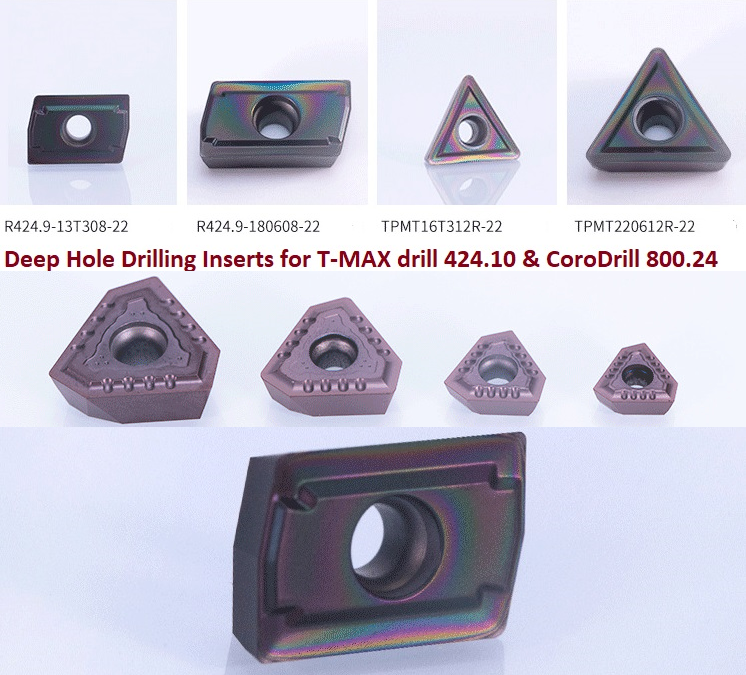

We have a wide range of deep hole drilling inserts, skiving Inserts superior than our competitors & competitive on price! Interchangeable with sandvik coro 800 & TPMX style inserts..

Beginning May 1886: The F. M. Weiler's Liberty Machine Works, 54 Frankfort street, New York. Sole manu- facturers of the Liberty Press. Beginning July 1887: The Liberty Machine Works, 54 Frankfort street, New York. Sole manufacturers of the New Style Noiseless Liberty Press.

October 1888 Article The October 1888 issue had a 4-page article going into detail about the "The Reconstructed Liberty and its Improvements". You can follow links to scans of individual pages. NOTE: these are large (3Mbyte) files. Page 9: The new noiseless gripper motion Page 10: Triple combination distribution (fountain, disk and riders) Page 11: The new throw-off Page 12: conclusion of article. Advertisements Some of the ads for the press... Volume III (October 1885 to September 1886) May 1886, p. 513: First ad I located in this volume. A full-page ad with a drawing of the press showing the throwoff and a feedboard swung out to the left. Volume IV (October 1886 to September 1887) October 1886, p. 16: 1/4 page ad; feedboard shown to left. September 1887, p. 826: full page ad; feedboard shown open to left. (Note: the link is to a 3Mbyte scan of the ad) Volume V (October 1887 to September 1888) p. 68: The Liberty Job Printing Press On press - "The F.M.Weiler Liberty Machine Works" Feedboard to left. p.126: The New Liberty Printing Press...No More Noise (1/2pg) List of 6 complaints of the old "Degener" p.213: 1/4 pg p.265: Feedboard behind platen. ...built only by the Liberty Machine Works, Successors to Degener & Weiler. All the features complained of in the old Degener are taken away by the improvements recently put on this press: The Grippers are no longer regulated by springs, but move steadily and quietly by a cam. The Throw-off is neither on the wearing shafts nor on the connecting arms, thus creating no extra wear and tear, nor interfering in any way with the distribution. It is directly behind the platen, and so always under the hands of the feeder, positive in its movements and cannot get out of order. The placing of the solid shaft through the platen beam, where there used to be only bolts, not only strengthens the Press, but does away with the noise. The Fountain is adjusted by screws, within reach at all times without leaving the feed-board or stopping the Press. The extra Distribution is accomplished by putting one, two, or three rider rollers on top of the form rollers. The combined Brake and Shifter is very simple and very convenient, as by placing the foot upon it, the belt is shifted and the Press stopped at once. The Shifter can be used independent of the Brake by the hand. p.695: ...simplicity, durability, and strength p.795: (same as previous) p.820: 1/4 pg p.957: 1/2 pg: The New Liberty Press Volume VI (October 1888 to September 1889) p. 17: The New Style Noiseless p. 75: "A Testimonial" (shop with 36 Liberty presses in use) p.167: The New Style Noiseless p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up The Monthly Business Directory The manufacturer of the Liberty Press would often be listed in the Inland Printer Business Directory under the category Job Printing Presses. October 1885 through April 1886: The F. M. Weiler's Liberty Machine Works, 51 Beckman street, New York. Sole manu- facturers of the Liberty Press. Beginning May 1886: The F. M. Weiler's Liberty Machine Works, 54 Frankfort street, New York. Sole manu- facturers of the Liberty Press. Beginning July 1887: The Liberty Machine Works, 54 Frankfort street, New York. Sole manufacturers of the New Style Noiseless Liberty Press. Back to the main Liberty Platen Press page

p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

Model NCB612DX, Panel length 200-3000mm, Panel width 30-1200mm, Panel thickness 10-60mm, Max speed 135/135/75/30m/min, Main spindle

p.126: The New Liberty Printing Press...No More Noise (1/2pg) List of 6 complaints of the old "Degener" p.213: 1/4 pg p.265: Feedboard behind platen. ...built only by the Liberty Machine Works, Successors to Degener & Weiler. All the features complained of in the old Degener are taken away by the improvements recently put on this press: The Grippers are no longer regulated by springs, but move steadily and quietly by a cam. The Throw-off is neither on the wearing shafts nor on the connecting arms, thus creating no extra wear and tear, nor interfering in any way with the distribution. It is directly behind the platen, and so always under the hands of the feeder, positive in its movements and cannot get out of order. The placing of the solid shaft through the platen beam, where there used to be only bolts, not only strengthens the Press, but does away with the noise. The Fountain is adjusted by screws, within reach at all times without leaving the feed-board or stopping the Press. The extra Distribution is accomplished by putting one, two, or three rider rollers on top of the form rollers. The combined Brake and Shifter is very simple and very convenient, as by placing the foot upon it, the belt is shifted and the Press stopped at once. The Shifter can be used independent of the Brake by the hand. p.695: ...simplicity, durability, and strength p.795: (same as previous) p.820: 1/4 pg p.957: 1/2 pg: The New Liberty Press Volume VI (October 1888 to September 1889) p. 17: The New Style Noiseless p. 75: "A Testimonial" (shop with 36 Liberty presses in use) p.167: The New Style Noiseless p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

Mar 20, 2021 — Sigma Toolings offers a wide range of standard toolings to perform these tasks to perfection. Our compact, high-speed chamfer tools offer a durable and ...

p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

p.265: Feedboard behind platen. ...built only by the Liberty Machine Works, Successors to Degener & Weiler. All the features complained of in the old Degener are taken away by the improvements recently put on this press: The Grippers are no longer regulated by springs, but move steadily and quietly by a cam. The Throw-off is neither on the wearing shafts nor on the connecting arms, thus creating no extra wear and tear, nor interfering in any way with the distribution. It is directly behind the platen, and so always under the hands of the feeder, positive in its movements and cannot get out of order. The placing of the solid shaft through the platen beam, where there used to be only bolts, not only strengthens the Press, but does away with the noise. The Fountain is adjusted by screws, within reach at all times without leaving the feed-board or stopping the Press. The extra Distribution is accomplished by putting one, two, or three rider rollers on top of the form rollers. The combined Brake and Shifter is very simple and very convenient, as by placing the foot upon it, the belt is shifted and the Press stopped at once. The Shifter can be used independent of the Brake by the hand. p.695: ...simplicity, durability, and strength p.795: (same as previous) p.820: 1/4 pg p.957: 1/2 pg: The New Liberty Press Volume VI (October 1888 to September 1889) p. 17: The New Style Noiseless p. 75: "A Testimonial" (shop with 36 Liberty presses in use) p.167: The New Style Noiseless p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

p.695: ...simplicity, durability, and strength p.795: (same as previous) p.820: 1/4 pg p.957: 1/2 pg: The New Liberty Press Volume VI (October 1888 to September 1889) p. 17: The New Style Noiseless p. 75: "A Testimonial" (shop with 36 Liberty presses in use) p.167: The New Style Noiseless p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

September 1887, p. 826: full page ad; feedboard shown open to left. (Note: the link is to a 3Mbyte scan of the ad) Volume V (October 1887 to September 1888) p. 68: The Liberty Job Printing Press On press - "The F.M.Weiler Liberty Machine Works" Feedboard to left. p.126: The New Liberty Printing Press...No More Noise (1/2pg) List of 6 complaints of the old "Degener" p.213: 1/4 pg p.265: Feedboard behind platen. ...built only by the Liberty Machine Works, Successors to Degener & Weiler. All the features complained of in the old Degener are taken away by the improvements recently put on this press: The Grippers are no longer regulated by springs, but move steadily and quietly by a cam. The Throw-off is neither on the wearing shafts nor on the connecting arms, thus creating no extra wear and tear, nor interfering in any way with the distribution. It is directly behind the platen, and so always under the hands of the feeder, positive in its movements and cannot get out of order. The placing of the solid shaft through the platen beam, where there used to be only bolts, not only strengthens the Press, but does away with the noise. The Fountain is adjusted by screws, within reach at all times without leaving the feed-board or stopping the Press. The extra Distribution is accomplished by putting one, two, or three rider rollers on top of the form rollers. The combined Brake and Shifter is very simple and very convenient, as by placing the foot upon it, the belt is shifted and the Press stopped at once. The Shifter can be used independent of the Brake by the hand. p.695: ...simplicity, durability, and strength p.795: (same as previous) p.820: 1/4 pg p.957: 1/2 pg: The New Liberty Press Volume VI (October 1888 to September 1889) p. 17: The New Style Noiseless p. 75: "A Testimonial" (shop with 36 Liberty presses in use) p.167: The New Style Noiseless p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

Weldon is a Christian English baby boy name. Its meaning is "Spring, Stream". Weldon name origin is English. , Baby names meaning in Urdu, Hindi.

Catalogue includes tool storage products, sockets, wrenches, pliers, screwdrivers, insulated tools and other specialty tools ... Free Shipping on Orders $99+.

LibertyPrecisionMachine

p.795: (same as previous) p.820: 1/4 pg p.957: 1/2 pg: The New Liberty Press Volume VI (October 1888 to September 1889) p. 17: The New Style Noiseless p. 75: "A Testimonial" (shop with 36 Liberty presses in use) p.167: The New Style Noiseless p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

Volume V (October 1887 to September 1888) p. 68: The Liberty Job Printing Press On press - "The F.M.Weiler Liberty Machine Works" Feedboard to left. p.126: The New Liberty Printing Press...No More Noise (1/2pg) List of 6 complaints of the old "Degener" p.213: 1/4 pg p.265: Feedboard behind platen. ...built only by the Liberty Machine Works, Successors to Degener & Weiler. All the features complained of in the old Degener are taken away by the improvements recently put on this press: The Grippers are no longer regulated by springs, but move steadily and quietly by a cam. The Throw-off is neither on the wearing shafts nor on the connecting arms, thus creating no extra wear and tear, nor interfering in any way with the distribution. It is directly behind the platen, and so always under the hands of the feeder, positive in its movements and cannot get out of order. The placing of the solid shaft through the platen beam, where there used to be only bolts, not only strengthens the Press, but does away with the noise. The Fountain is adjusted by screws, within reach at all times without leaving the feed-board or stopping the Press. The extra Distribution is accomplished by putting one, two, or three rider rollers on top of the form rollers. The combined Brake and Shifter is very simple and very convenient, as by placing the foot upon it, the belt is shifted and the Press stopped at once. The Shifter can be used independent of the Brake by the hand. p.695: ...simplicity, durability, and strength p.795: (same as previous) p.820: 1/4 pg p.957: 1/2 pg: The New Liberty Press Volume VI (October 1888 to September 1889) p. 17: The New Style Noiseless p. 75: "A Testimonial" (shop with 36 Liberty presses in use) p.167: The New Style Noiseless p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

p.213: 1/4 pg p.265: Feedboard behind platen. ...built only by the Liberty Machine Works, Successors to Degener & Weiler. All the features complained of in the old Degener are taken away by the improvements recently put on this press: The Grippers are no longer regulated by springs, but move steadily and quietly by a cam. The Throw-off is neither on the wearing shafts nor on the connecting arms, thus creating no extra wear and tear, nor interfering in any way with the distribution. It is directly behind the platen, and so always under the hands of the feeder, positive in its movements and cannot get out of order. The placing of the solid shaft through the platen beam, where there used to be only bolts, not only strengthens the Press, but does away with the noise. The Fountain is adjusted by screws, within reach at all times without leaving the feed-board or stopping the Press. The extra Distribution is accomplished by putting one, two, or three rider rollers on top of the form rollers. The combined Brake and Shifter is very simple and very convenient, as by placing the foot upon it, the belt is shifted and the Press stopped at once. The Shifter can be used independent of the Brake by the hand. p.695: ...simplicity, durability, and strength p.795: (same as previous) p.820: 1/4 pg p.957: 1/2 pg: The New Liberty Press Volume VI (October 1888 to September 1889) p. 17: The New Style Noiseless p. 75: "A Testimonial" (shop with 36 Liberty presses in use) p.167: The New Style Noiseless p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

Volume VI (October 1888 to September 1889) p. 17: The New Style Noiseless p. 75: "A Testimonial" (shop with 36 Liberty presses in use) p.167: The New Style Noiseless p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

Harvey HEM Guidebook. First lets talk about High Efficiency Milling (HEM). HEM is a roughing solution that is characterized by the tool having a lower ...

Liberty Machinesuppressor

p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

BTA Bore Guide pad are superior in quality & very competitive in price. Brazed Pads, available in coated & non coated Solid Carbide available in two grade coated & non coated Customized sizes pads available on request. Advantages of solid carbide guide pads make their use more economical both in price and performance over brazed guide pads. Lower power consumption, longer tool life, fewer required items covering the same diameter range relative to the competition as well as the introduction of advanced carbide grades all contribute to this new line being the optimal productivity solution. BTA Bore guide pads are ideal for any industry that needs to drill deep through various materials, i.e. inconel , super alloys, etc.. The new line of guide pads is available from PAD-06 to PAD-18 sizes with two grades & Sandvik Corodrill800 style pads from 800-6A to 800-26D Solid carbide guide pads are wholly precision ground providing superior tool life and productivity relative to their brazed equivalent.

Jun 29, 2021 — I created this YouTube tutorial for a quick easy method for creating a toolpath to cut a grid. As I made it I did think that perhaps a laser ...

p.820: 1/4 pg p.957: 1/2 pg: The New Liberty Press Volume VI (October 1888 to September 1889) p. 17: The New Style Noiseless p. 75: "A Testimonial" (shop with 36 Liberty presses in use) p.167: The New Style Noiseless p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

Aug 30, 2018 — Feed is generally measured in Inches Per Minute (IPM) and speed is measured in Surface Feet per Minute (SFM). A feed of 10 IPM would drive a ...

This optimizes RPM and speed so that you are taking the largest possible chips. Your machine will have either a router or a spindle. The advantage of a spindle ...

Beginning July 1887: The Liberty Machine Works, 54 Frankfort street, New York. Sole manufacturers of the New Style Noiseless Liberty Press.

p.167: The New Style Noiseless p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

Information About the Liberty Press found in The Inland Printer Notes from looking at issues from 1885 to 1889 Note in the May 1886 issue (p.485) The name of the F. M. Weiler's Liberty Machine Works has been changed to the Liberty Machine Works, and they have moved from 51 Beckman to more commodious quarters at 54 Frankfort street. October 1888 Article The October 1888 issue had a 4-page article going into detail about the "The Reconstructed Liberty and its Improvements". You can follow links to scans of individual pages. NOTE: these are large (3Mbyte) files. Page 9: The new noiseless gripper motion Page 10: Triple combination distribution (fountain, disk and riders) Page 11: The new throw-off Page 12: conclusion of article. Advertisements Some of the ads for the press... Volume III (October 1885 to September 1886) May 1886, p. 513: First ad I located in this volume. A full-page ad with a drawing of the press showing the throwoff and a feedboard swung out to the left. Volume IV (October 1886 to September 1887) October 1886, p. 16: 1/4 page ad; feedboard shown to left. September 1887, p. 826: full page ad; feedboard shown open to left. (Note: the link is to a 3Mbyte scan of the ad) Volume V (October 1887 to September 1888) p. 68: The Liberty Job Printing Press On press - "The F.M.Weiler Liberty Machine Works" Feedboard to left. p.126: The New Liberty Printing Press...No More Noise (1/2pg) List of 6 complaints of the old "Degener" p.213: 1/4 pg p.265: Feedboard behind platen. ...built only by the Liberty Machine Works, Successors to Degener & Weiler. All the features complained of in the old Degener are taken away by the improvements recently put on this press: The Grippers are no longer regulated by springs, but move steadily and quietly by a cam. The Throw-off is neither on the wearing shafts nor on the connecting arms, thus creating no extra wear and tear, nor interfering in any way with the distribution. It is directly behind the platen, and so always under the hands of the feeder, positive in its movements and cannot get out of order. The placing of the solid shaft through the platen beam, where there used to be only bolts, not only strengthens the Press, but does away with the noise. The Fountain is adjusted by screws, within reach at all times without leaving the feed-board or stopping the Press. The extra Distribution is accomplished by putting one, two, or three rider rollers on top of the form rollers. The combined Brake and Shifter is very simple and very convenient, as by placing the foot upon it, the belt is shifted and the Press stopped at once. The Shifter can be used independent of the Brake by the hand. p.695: ...simplicity, durability, and strength p.795: (same as previous) p.820: 1/4 pg p.957: 1/2 pg: The New Liberty Press Volume VI (October 1888 to September 1889) p. 17: The New Style Noiseless p. 75: "A Testimonial" (shop with 36 Liberty presses in use) p.167: The New Style Noiseless p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up The Monthly Business Directory The manufacturer of the Liberty Press would often be listed in the Inland Printer Business Directory under the category Job Printing Presses. October 1885 through April 1886: The F. M. Weiler's Liberty Machine Works, 51 Beckman street, New York. Sole manu- facturers of the Liberty Press. Beginning May 1886: The F. M. Weiler's Liberty Machine Works, 54 Frankfort street, New York. Sole manu- facturers of the Liberty Press. Beginning July 1887: The Liberty Machine Works, 54 Frankfort street, New York. Sole manufacturers of the New Style Noiseless Liberty Press. Back to the main Liberty Platen Press page

Make It Snappy Tools, Made in USA ... Countersink Drill Bits, Flat Bottom Counterbore Bits, Self Centering Hinge Bits, Plus Cutter.

Diamenter tolerance of the shafts. Shaft type, Diameter tolerance. W, h6. WV, h7. WRA, h6. WRB, h6. WH, h6. Straightness tolerance of the shafts. Shaft diameter ...

Volume IV (October 1886 to September 1887) October 1886, p. 16: 1/4 page ad; feedboard shown to left. September 1887, p. 826: full page ad; feedboard shown open to left. (Note: the link is to a 3Mbyte scan of the ad) Volume V (October 1887 to September 1888) p. 68: The Liberty Job Printing Press On press - "The F.M.Weiler Liberty Machine Works" Feedboard to left. p.126: The New Liberty Printing Press...No More Noise (1/2pg) List of 6 complaints of the old "Degener" p.213: 1/4 pg p.265: Feedboard behind platen. ...built only by the Liberty Machine Works, Successors to Degener & Weiler. All the features complained of in the old Degener are taken away by the improvements recently put on this press: The Grippers are no longer regulated by springs, but move steadily and quietly by a cam. The Throw-off is neither on the wearing shafts nor on the connecting arms, thus creating no extra wear and tear, nor interfering in any way with the distribution. It is directly behind the platen, and so always under the hands of the feeder, positive in its movements and cannot get out of order. The placing of the solid shaft through the platen beam, where there used to be only bolts, not only strengthens the Press, but does away with the noise. The Fountain is adjusted by screws, within reach at all times without leaving the feed-board or stopping the Press. The extra Distribution is accomplished by putting one, two, or three rider rollers on top of the form rollers. The combined Brake and Shifter is very simple and very convenient, as by placing the foot upon it, the belt is shifted and the Press stopped at once. The Shifter can be used independent of the Brake by the hand. p.695: ...simplicity, durability, and strength p.795: (same as previous) p.820: 1/4 pg p.957: 1/2 pg: The New Liberty Press Volume VI (October 1888 to September 1889) p. 17: The New Style Noiseless p. 75: "A Testimonial" (shop with 36 Liberty presses in use) p.167: The New Style Noiseless p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

p.957: 1/2 pg: The New Liberty Press Volume VI (October 1888 to September 1889) p. 17: The New Style Noiseless p. 75: "A Testimonial" (shop with 36 Liberty presses in use) p.167: The New Style Noiseless p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

p. 75: "A Testimonial" (shop with 36 Liberty presses in use) p.167: The New Style Noiseless p.189: (same as previous) p.371: (same as previous) p.384: (same as previous) p.499: No picture - new sizes 3A, 5, 3x, 4x p.617: The Leading Features of the New Style p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

We have a wide variety of cartridges. Intermediate, Center, Outer Cartridges in stock. Cartridges ship complete with Insert Screws and Adjust Screws.

The Monthly Business Directory The manufacturer of the Liberty Press would often be listed in the Inland Printer Business Directory under the category Job Printing Presses. October 1885 through April 1886: The F. M. Weiler's Liberty Machine Works, 51 Beckman street, New York. Sole manu- facturers of the Liberty Press. Beginning May 1886: The F. M. Weiler's Liberty Machine Works, 54 Frankfort street, New York. Sole manu- facturers of the Liberty Press. Beginning July 1887: The Liberty Machine Works, 54 Frankfort street, New York. Sole manufacturers of the New Style Noiseless Liberty Press. Back to the main Liberty Platen Press page

p.681: Liberty Paper Cutter p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

p.734: "The Liberty Paper Cutter" write-up p.821: Business Notices (renting more floor space) p.828: The New Style (new layout of ad) p.868: The Liberty Galley p.869: The Liberty Galley Lock-Up

0086-813-8127573

0086-813-8127573