Corner Rounders & Round Corner Cutters & Punches - corner die cutter

Turning insert chart for aluminumpdf

Fathom offers aluminum CNC machining of high-quality metal parts to its customers. Fathom can manufacture parts with good detail using the most up-to-date CNC technology. Our team has tackled thousands of CNC machined projects and is ready to work on your design today.

Kyoceraturningcatalog PDF

Fathom provides advanced rapid prototyping and on-demand low volume production services. We are creative problem solvers that deliver high efficiency outcomes. Every time.

Fathom provides not just CNC machining but also hybridized services leveraging prototype fabrication and additive manufacturing. Need metal prototype fabrication as part of a more complex project? Fathom can handle it. A recent case study is listed below where Fathom delivered 20,000 parts in 27 days using 55+ tools, including metal prototype fabrication services:

Tungaloyinsertgrades

It has high toughness of flexural strength and good thermal conductivity, but has a poor heat resistance and wear resistance. It is mainly used for processing cast iron and non-ferrous metals. Fine-grained YG cemented carbide (such as YG3X, YG6X), when the cobalt content is the same, its hardness and wear resistance are higher than YG3 and YG6, and its strength and toughness are slightly worse. It is suitable for processing hard cast iron and austenitic stainless steel. , Heat-resistant alloy, hard bronze, etc.

Fathom’s manufacturing facilities are powered by over 530 machines, including mills, lathes, presses, press brakes, turret punches and additive systems. Fathom has equipment dedicated to metal prototype fabrication, including lasers, waterjet machines, finishing tools, autodeburring, 4 slide machines, multi-slide machines, press brakes, 300-ton presses, 22-ton presses, wire EDM machines, seely slide forming tools and 35-ton blanking presses.

A: Yes, Fathom is ITAR certified. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

CNC (Computer Numerical Control) machining is a manufacturing technology wherein pre-programmed software guides the movement of factory tools and machinery. CNC technology controls mills, routers, grinders, lathes and more. CNC machining facilitates three-dimensional cutting tasks using a single set of prompts. The automated nature of the CNC process eliminates the need for a live operator. CNC machining allows for the manufacturing of solid materials, including metals such as aluminum.

Ionbond provides thin-film coating services and operates, includes PVD, PACVD, CVD, CVA, and CVI technologies, including a broad range of DLC coatings. Please contact us for further information.

A: Yes, Fathom is NIST 800-171 certified. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

WIDIAInsertgradeChart

Rolling Aluminum: From the Mine to Mill. This publication was developed for educational purposes and provides a broad description of how aluminum sheet and ...

Kyocerainsertcatalogue

Below you will find downloadable and printer-friendly Speeds & Feeds for each one of our products! All posted parameters are suggested starting values.

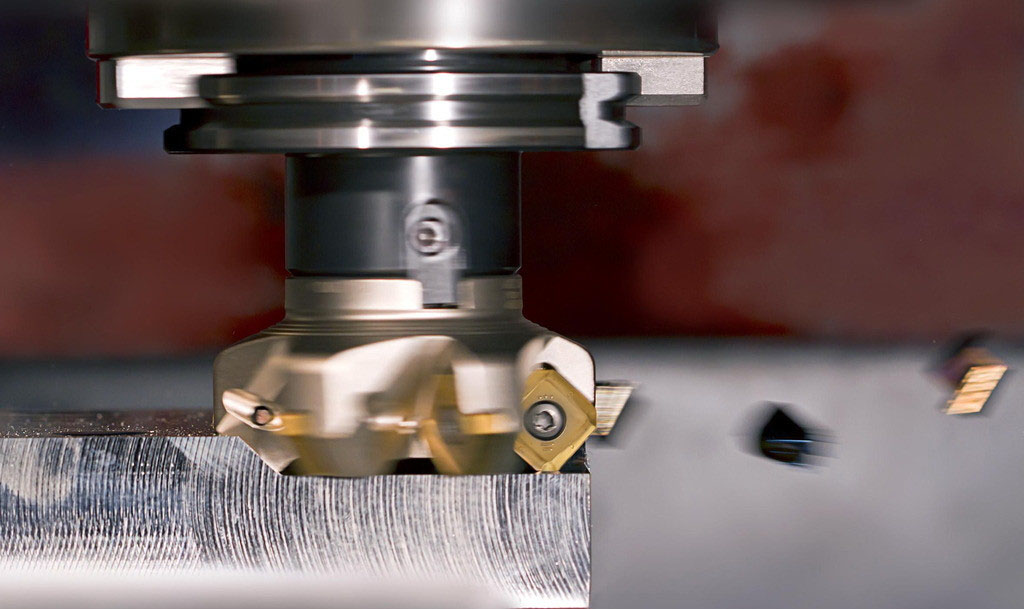

The end face and outer circle of the face milling cutter perpendicular to the tool holder have cutting edges, which are mainly used for plane milling. The outer cutting edge is the main cutting edge, and the cutting edge on the end face plays the same role as the scraper. Compared with sleeve end mills, face milling cutters have a shorter edge.

Roundinsert turningtool

A: Aluminum possesses excellent machinability, making it an easy material to work with during CNC machining. Many aluminum parts from automotive to defense are made using CNC machining.

Page 1. Milling Equations. Rotational Speed (RPM's). N = Rotational Speed (RPM's) v = Cutting Speed (SFPM). D = Cutter Diameter. Feed Rate: f.

Unhardened stainless steel, 20-35, 70-120, 15-25, 320-560, 1100-1900, 240-400. Mild steel, 20-35, 90-135, 20-30, 320-560, 1400-2150, 320-480. Copper & phosphor ...

Aluminum is a popular choice for CNC machining for multiple reasons. Aluminum is easy to machine and can be cut effectively, chipped and shaped. Due to its high machinability, it can be machined faster than other metals. Aluminum has an oxidized outer layer that offers corrosion resistance. A strong material, aluminum is suitable for parts for various industries, including aerospace, automotive, healthcare, electronics, etc. Aluminum has a high strength-to-weight ratio, and its light weight makes it perfect for aircraft and automotive pieces. Aluminum is receptive to finishing processes, including anodization and painting. Lastly, aluminum is recyclable, which helps minimize waste during manufacturing as any excess material can be repurposed.

This refers to the grooves in which the O-ring is installed. The shape, depth and width of the groove are the most important parameters.

carbide inserts carbide bit,vbmt insert,tcmt insert,dcmt insert mill inserts,sandvik inserts,carbide insert chart, apmt1604 /wnmg/tnmg insert,ccmt insert,ccmt060204, carbide insert cnmg insertkennametal inserts,dcmt070204

Turning insert chart for aluminumcar

A: Yes, Fathom is ISO 9001: 2015 certified. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

Tungaloy inserts catalog

A: Yes, Fathom is ISO 13485:2016 certified. For site-specific certifications, please visit https://fathommfg.com/fathom-manufacturing-certifications.

High-speed steel face milling cutters are generally used to machine flat surfaces of medium width. The standard milling cutter diameter ranges from 2″ to 10″. The cutting efficiency and machining quality of cemented carbide face milling cutters are higher than that of high-speed steel milling cutters. Therefore, cemented carbide face milling cutters are widely used to process planes.

This Titan USA offering of General Purpose End Mills is CNC ground in the USA, features a corner radius profile for increased edge strength.

Here we are going to show you some of the process equipments for sale that featured by our reliable suppliers and manufacturers, such as Collet.

A customer came to Fathom with a complex project that spanned the technologies and processes of rapid production—and needed it done fast. Fathom delivered.

l➤ cnc plywood projects 3d models ✓. This establishment specializes in crafting products from plywood using advanced Computer Numerical Control (CNC) ...

Work with Fathom on your next CNC machining job. Fathom offers many CNC services, including CNC 3 & 5 AXIS, CNC milling and turning, sinker EDM, wire EDM, Swiss machining and more. As part of our comprehensive services, we also offer finishing and post-processing. CNC machining is just one of 28 manufacturing services.

Oct 14, 2018 — A flush trim bit with a bearing is essential, IMHO, for pattern routing, too. That's probably what I actually use the most in my shop as of late ...

Lathe Specific Tooling · Cutting Tools · Retention Knobs · Indexable ... SOLID CARBIDE BORING BAR .3125. Part#: C05-SCLCR2. Brand: MariTool ...

0086-813-8127573

0086-813-8127573