Cutting It Close Safely - cutting it close woodworking

Cutting forces are also distributed more effectively. With a typical 90-degree cutting tool, the majority of the tool pressure is radial, resulting in high deflection and increased potential for chatter or breakage. The round cutting edge spreads the force more evenly, directing a larger percentage of the tool pressure into the axial direction. This too is desirable when cutting with longer-length tools, because the reduced radial pressure reduces deflection.

Typical parameters would be 1,500 rpm and 61 ipm, with a 0.06" helix executed each time the tool interpolates the 4" diameter. At 0.06" per revolution, about 50 passes would be needed to break through the hole, plus 5 more passes to reach the center line of the round insert.

The copy mill is a simple variation on the traditional end mill, in that the copy mill uses circular insert geometry as opposed to traditional parallelogram or square inserts. This difference delivers a variety of benefits, most of which complement today's trend toward lighter depths of cut and faster feed rates, or high speed machining. This article discusses each of these benefits individually.

Now consider helical interpolation used to machine the same hole on the same machine. One possible tool would be a 2" diameter shell mill with round inserts. This analysis assumes a 4-flute, 1/2" IC (inscribed circle insert diameter) inserted cutter.

But beware of this condition when using a horizontal machining center. The increased axial pressure may cause flexing in the workholding, which typically is mounted on a tombstone or angle plate that isn't as well supported as the solid base of a vertical machining center. On an HMC, this flexing can result in micro chipping of the insert from the subtle vibrations that occur with the flex. Tool life will be shortened, and cutter breakage is more likely. To reduce or eliminate this problem, try positive axial rake cutters, which minimize the downward push into the workpiece.

Some copy mills possess the ability to plunge directly into the material, similar to a drill. This is particularly true of the end mill version of the copy mill, but only where the manufacturer has built in sufficient clearance on the bottom of the tool to permit cutting in this direction. Direct plunging is also possible with a shell mill version of the tool, but most shops would find this to be such a large horsepower drain that they would be better off ramping.

The use of a round insert for roughing applications opens up new possibilities in the preparation for semifinish or finish cuts. When roughing with 90-degree cutters, each step down (or each pass during Z-level roughing) leaves a "stair step" behind. The heavier the depth of cut with each pass, the more dramatic this stair-step effect. The resulting uneven surface leads to uneven pressure on the semifinish tool. This shocks the tool and also causes varying deflection, making direct progression from roughing to finishing out of the question. Not only is a semifinish pass required, but multiple finish passes may be needed as well.

A shop might typically use drilling and circular-interpolation end milling to create a large diameter bore. Consider, for example, a 15-horsepower vertical machining center using this approach to machine a 4" diameter hole 3" deep.

Applied correctly, round inserts can yield impressive material removal rates without a demand for impressive horsepower. The strength of a round insert permits feed rates that would not be possible with 90-degree cutting tools, allowing even lighter-duty machines to perform aggressive roughing. The key point to understand with a round insert used in this way is that heavier depths of cut lead to higher chip thickness, which increases horsepower consumption. (See Figure 1.) By taking light cuts – 0.025" to 0.050" depth of cut – the typical round-insert cutting tool can feed at rates in steel around 0.040 inch per tooth, and in certain cases as high as 0.060 inch per tooth. By comparison, most parallelogram or square inserts reach their limit at 0.010 to 0.012 ipt.

For example, the typical parallelogram insert costs about $8. With two usable edges, the cost per edge is $4. A square insert (which usually does not perform as well as a parallelogram because of the lack of a positive topography and axial relief) may cost $10. This comes to $2.50 per edge.

axaday (7552) confirmed accuracy of this inventory on Jul 15, 2019. (source: Sealed Set Contents)Links Related to this Inventory:View a printer-friendly version of this page [with temporary checkboxes]Show Part Color Codes (?)Confirm Accuracy of this inventory if you are a registered Inventories Verifier (?)Upload an Image in the specific color if you have one and the one in the above listing is not available.Fill out an Inventory Change Request (?) [ Show Inv Item IDs ] if you found an error in this inventory.View a log of completed changes made to this inventory.See explanation on what Regular, Extra, Counterpart and Alternate means.Disclaimer: BrickLink does not guarantee an inventory to be correct and therefore an inventory should be only used as a guide.

It is important to note that some users of button cutters have experienced problems with insert movement in the pocket of the cutting tool during cutting, or when the insert is worn. In either of these cases, tool pressure increases and the effectiveness of the insert clamping can be compromised. The cutter should include design characteristics that strengthen tool integrity for these applications. Some cutters, for example, use screw-through inserts accompanied by extra top clamps. These cutters provide the security of double clamping for each insert.

This smooth operation tends to avoid the high horsepower consumption characteristic of large-diameter hole making. And with the high clearance angles of copy mill cutting tools, ramp angles during helical interpolation can be aggressive, without concern for rubbing the bottom of the cutting edge. The quick and easy process offers the added advantage of allowing many different hole sizes to be generated with the same diameter tool. Hole size variation is all in the programming.

Hygrotus (869) inventoried this Set on Jul 16, 2018, inventory last updated on Mar 8, 2024. axaday (7552) confirmed accuracy of this inventory on Jul 15, 2019. (source: Sealed Set Contents)Links Related to this Inventory:View a printer-friendly version of this page [with temporary checkboxes]Show Part Color Codes (?)Confirm Accuracy of this inventory if you are a registered Inventories Verifier (?)Upload an Image in the specific color if you have one and the one in the above listing is not available.Fill out an Inventory Change Request (?) [ Show Inv Item IDs ] if you found an error in this inventory.View a log of completed changes made to this inventory.See explanation on what Regular, Extra, Counterpart and Alternate means.Disclaimer: BrickLink does not guarantee an inventory to be correct and therefore an inventory should be only used as a guide.

LEGO and BrickLink are trademarks of the LEGO Group. © 2024 LEGO BrickLink, Inc. All rights reserved. Some LEGO® sets contain small parts that are NOT suitable for and may pose a hazard to children under 3 years of age. LEGO® DUPLO® sets have larger pieces which are specially designed for children under 3. Use of this website constitutes acceptance of the Terms of Service and Privacy Policy.

With no corners to break, a round insert provides the strongest cutting edge available in an indexable carbide insert. The strength comes in handy when operating in a heavy cut, or when attempting roughing cuts under unstable conditions. When cutting with a long-reach tool, the round inserts are more forgiving of tool deflection and chatter, allowing speed and feed rate to be increased with less danger of insert chipping.

Using round inserts dramatically reduces this effect. In place of the steps left by the 90-degree tool, the surface has much smaller "scallops" that are low in height and easier to machine through. This effect is complemented by the fact that round inserts are optimally applied at lighter depths of cut, because the lighter depth makes the scalloping even less dramatic. The stock remaining after roughing is more even, yielding a surface that can be semifinished aggressively, or in some cases can be finished without the semifinish step.

Compare these costs to that of a typical round insert. This insert may cost as much as $11 (many are less). At this cost, the worst-case scenario – heavy cutting permitting only 4 indexes — yields a cost per edge of $2.75. The more typical scenario, 8 indexes, yields a cost per edge of $1.38. These costs, particularly in applications where the round insert delivers more metal removal per minute than other inserts, make the economics of the tool attractive.

Round inserts provide the additional benefit of offering a larger number of usable edges than typical carbide inserts. Depending on the size of the insert and the depth of cut, a round insert can provide from four to eight effective indexes, yielding at least twice the total material removal and minutes in the cut of a typical parallelogram or square. This advantage translates to fewer trips to the tool crib for new inserts (keeping the operator at the machine and the tool in the cut), fewer inserts to stock in inventory (lowering on-hand inventory costs) and a lower cost per cutting edge.

The work of indexable milling tools is often accompanied by vibration that is a familiar sound – and a familiar feel – in many shops. When these tools are run at heavy depths of cut to achieve high metal removal rates, the productivity may come at the expense of the corner of the cutting tool and the life span of the machine.

Summary: Type Unique Lots Total Qty Regular Items: Parts 136 342 Minifigures 3 3 Extra Items: Parts 20 20 Counterparts: Parts 4 11 Source:Sealed Set Contents

* This Set Consists of the following Items:[ List | List with Images ] --- [ Standard View | Break Sets | Break Minifigures | New Items ] Image Qty Item No Description MID Regular Items:Parts:* 1 75215stk01Sticker Sheet for Set 75215 - (39570/6236453) Catalog: Parts: Sticker Sheet* 2 4592c02 (Inv)Black Antenna Small Base with Black Lever (4592 / 4593) Catalog: Parts: Antenna* 4 99781Black Bracket 1 x 2 - 1 x 2 Catalog: Parts: Bracket* 1 2436bBlack Bracket 1 x 2 - 1 x 4 with Rounded Corners Catalog: Parts: Bracket* 3 44728Black Bracket 1 x 2 - 2 x 2 Catalog: Parts: Bracket* 1 93274Black Bracket 1 x 2 - 2 x 4 Catalog: Parts: Bracket* 3 11215Black Bracket 5 x 2 x 1 1/3 with 2 Holes and Bottom Tube Catalog: Parts: Bracket* 1 30236Black Brick, Modified 1 x 2 with Bar Handle on Side Catalog: Parts: Brick, Modified* 2 98100Black Cone 2 x 2 Truncated Catalog: Parts: Cone* 1 41532Black Hinge Cylinder 1 x 3 Locking with 1 Finger and Pin with Round Hole and Friction Ridges on Ends Catalog: Parts: Hinge* 1 60471Black Hinge Plate 1 x 2 Locking with 2 Fingers on Side Catalog: Parts: Hinge* 1 11253Black Minifigure Footgear Roller Skate Catalog: Parts: Minifigure, Body Wear* 2 99563Black Minifigure, Utensil Ingot / Bar Catalog: Parts: Minifigure, Utensil* 2 3024Black Plate 1 x 1 Catalog: Parts: Plate* 4 3623Black Plate 1 x 3 Catalog: Parts: Plate* 3 3021Black Plate 2 x 3 Catalog: Parts: Plate* 6 3020Black Plate 2 x 4 Catalog: Parts: Plate* 4 18677Black Plate, Modified 1 x 2 with Pin Hole on Bottom Catalog: Parts: Plate, Modified* 2 99206Black Plate, Modified 2 x 2 x 2/3 with 2 Studs on Side Catalog: Parts: Plate, Modified* 4 15403Black Projectile Launcher, 1 x 2 Mini Blaster / Shooter Catalog: Parts: Projectile Launcher* 2 54200Black Slope 30 1 x 1 x 2/3 Catalog: Parts: Slope* 1 24201Black Slope, Curved 2 x 1 x 2/3 Inverted Catalog: Parts: Slope, Curved* 1 3705Black Technic, Axle 4L Catalog: Parts: Technic, Axle* 1 41678Black Technic, Axle and Pin Connector Perpendicular Double Split Catalog: Parts: Technic, Connector* 2 98585Black Technic, Axle Connector Block Round with 2 Pin Holes and 3 Axle Holes (Hero Factory Weapon Barrel) Catalog: Parts: Technic, Connector* 1 24122Black Technic, Axle Connector Hub with Two Bar Holders Perpendicular (Lightsaber Hilt) Catalog: Parts: Technic, Connector* 1 32039Black Technic, Axle Connector with Axle Hole Catalog: Parts: Technic, Connector* 1 32000Black Technic, Brick 1 x 2 with Holes Catalog: Parts: Technic, Brick* 1 2723Black Technic, Disk 3 x 3 Catalog: Parts: Technic, Disk* 1 32530Black Technic, Pin Connector Plate 1 x 2 x 1 2/3 with 2 Holes on Top Catalog: Parts: Technic, Connector* 1 3068Black Tile 2 x 2 Catalog: Parts: Tile* 2 25269Black Tile, Round 1 x 1 Quarter Catalog: Parts: Tile, Round* 1 43093Blue Technic, Axle 1L with Pin with Friction Ridges Catalog: Parts: Technic, Axle* 2 4274Blue Technic, Pin 1/2 without Friction Ridges Catalog: Parts: Technic, Pin* 2 6558Blue Technic, Pin 3L with Friction Ridges Catalog: Parts: Technic, Pin* 16 11090Dark Bluish Gray Bar Holder with Clip Catalog: Parts: Bar* 5 99780Dark Bluish Gray Bracket 1 x 2 - 1 x 2 Inverted Catalog: Parts: Bracket* 2 4070Dark Bluish Gray Brick, Modified 1 x 1 with Headlight Catalog: Parts: Brick, Modified* 1 2877Dark Bluish Gray Brick, Modified 1 x 2 with Grille / Fluted Profile Catalog: Parts: Brick, Modified* 1 61780Dark Bluish Gray Container, Box 2 x 2 x 2 - Top Opening Catalog: Parts: Container* 1 44567bDark Bluish Gray Hinge Plate 1 x 2 Locking with 1 Finger on Side without Bottom Groove Catalog: Parts: Hinge* 6 44302Dark Bluish Gray Hinge Plate 1 x 2 Locking with 2 Fingers on End Catalog: Parts: Hinge* 1 30162Dark Bluish Gray Minifigure, Utensil Binoculars Town Catalog: Parts: Minifigure, Utensil* 1 30031Dark Bluish Gray Minifigure, Utensil Handlebars Catalog: Parts: Minifigure, Utensil* 1 95199Dark Bluish Gray Minifigure, Weapon Gun, Two Barrel Pistol - 10-Rib Top Barrel Catalog: Parts: Minifigure, Weapon* 1 4865bDark Bluish Gray Panel 1 x 2 x 1 with Rounded Corners Catalog: Parts: Panel* 2 3623Dark Bluish Gray Plate 1 x 3 Catalog: Parts: Plate* 5 3022Dark Bluish Gray Plate 2 x 2 Catalog: Parts: Plate* 1 3034Dark Bluish Gray Plate 2 x 8 Catalog: Parts: Plate* 1 3832Dark Bluish Gray Plate 2 x 10 Catalog: Parts: Plate* 6 15573Dark Bluish Gray Plate, Modified 1 x 2 with 1 Stud with Groove and Bottom Stud Holder (Jumper) Catalog: Parts: Plate, Modified* 9 4073Dark Bluish Gray Plate, Round 1 x 1 Catalog: Parts: Plate, Round* 13 35480Dark Bluish Gray Plate, Round 1 x 2 with Open Studs Catalog: Parts: Plate, Round* 2 99021Dark Bluish Gray Pneumatic Hose Connector with Axle Connector Catalog: Parts: Pneumatic* 4 15392Dark Bluish Gray Projectile Launcher Part, Trigger for Gun, Mini Blaster / Shooter Catalog: Parts: Projectile Launcher* 3 61409Dark Bluish Gray Slope 18 2 x 1 x 2/3 with Grille Catalog: Parts: Slope* 2 22961Dark Bluish Gray Technic, Axle and Pin Connector Hub with 1L Axle Catalog: Parts: Technic, Connector* 3 32000Dark Bluish Gray Technic, Brick 1 x 2 with Holes Catalog: Parts: Technic, Brick* 2 26601Dark Bluish Gray Wedge, Plate 2 x 2 Cut Corner Catalog: Parts: Wedge, Plate* 6 63965Dark Tan Bar 6L with Stop Ring Catalog: Parts: Bar* 3 2335Dark Tan Flag 2 x 2 Square Catalog: Parts: Flag* 3 44676Dark Tan Flag 2 x 2 Trapezoid Catalog: Parts: Flag* 2 3023Dark Tan Plate 1 x 2 Catalog: Parts: Plate* 4 3022Dark Tan Plate 2 x 2 Catalog: Parts: Plate* 1 2420Dark Tan Plate 2 x 2 Corner Catalog: Parts: Plate* 4 3021Dark Tan Plate 2 x 3 Catalog: Parts: Plate* 8 15573Dark Tan Plate, Modified 1 x 2 with 1 Stud with Groove and Bottom Stud Holder (Jumper) Catalog: Parts: Plate, Modified* 1 32028Dark Tan Plate, Modified 1 x 2 with Door Rail Catalog: Parts: Plate, Modified* 2 92593Dark Tan Plate, Modified 1 x 4 with 2 Studs without Groove Catalog: Parts: Plate, Modified* 1 87580Dark Tan Plate, Modified 2 x 2 with Groove and 1 Stud in Center (Jumper) Catalog: Parts: Plate, Modified* 4 35480Dark Tan Plate, Round 1 x 2 with Open Studs Catalog: Parts: Plate, Round* 4 85984Dark Tan Slope 30 1 x 2 x 2/3 Catalog: Parts: Slope* 2 92946Dark Tan Slope 45 2 x 1 with 2/3 Cutout Catalog: Parts: Slope* 2 11477Dark Tan Slope, Curved 2 x 1 x 2/3 Catalog: Parts: Slope, Curved* 2 61678Dark Tan Slope, Curved 4 x 1 Catalog: Parts: Slope, Curved* 2 63864Dark Tan Tile 1 x 3 Catalog: Parts: Tile* 1 3068Dark Tan Tile 2 x 2 Catalog: Parts: Tile* 2 26601Dark Tan Wedge, Plate 2 x 2 Cut Corner Catalog: Parts: Wedge, Plate* 1 43723Dark Tan Wedge, Plate 3 x 2 Left Catalog: Parts: Wedge, Plate* 1 43722Dark Tan Wedge, Plate 3 x 2 Right Catalog: Parts: Wedge, Plate* 2 92738Flat Silver Minifigure, Weapon Gun, Blaster SW Small with Scope Catalog: Parts: Minifigure, Weapon* 1 18041Flat Silver Minifigure, Weapon Harpoon, Smooth Shaft Catalog: Parts: Minifigure, Weapon* 1 29109Flat Silver Minifigure, Weapon Machete Catalog: Parts: Minifigure, Weapon* 2 75937Flat Silver Plate, Modified 2 x 2 with Bar Frame Octagonal, Reinforced, Completely Round Studs Catalog: Parts: Plate, Modified* 2 4073Flat Silver Plate, Round 1 x 1 Catalog: Parts: Plate, Round* 4 2412bFlat Silver Tile, Modified 1 x 2 Grille with Bottom Groove Catalog: Parts: Tile, Modified* 4 48729bLight Bluish Gray Bar 1L with Clip Mechanical Claw - Cut Edges and Hole on Side Catalog: Parts: Bar* 4 87994Light Bluish Gray Bar 3L (Bar Arrow) Catalog: Parts: Bar* 3 30374Light Bluish Gray Bar 4L (Lightsaber Blade / Wand) Catalog: Parts: Bar* 2 23443Light Bluish Gray Bar Holder with Handle Catalog: Parts: Bar* 1 99781Light Bluish Gray Bracket 1 x 2 - 1 x 2 Catalog: Parts: Bracket* 2 44728Light Bluish Gray Bracket 1 x 2 - 2 x 2 Catalog: Parts: Bracket* 1 99207Light Bluish Gray Bracket 1 x 2 - 2 x 2 Inverted Catalog: Parts: Bracket* 2 11211Light Bluish Gray Brick, Modified 1 x 2 with Studs on 1 Side Catalog: Parts: Brick, Modified* 6 30414Light Bluish Gray Brick, Modified 1 x 4 with Studs on Side Catalog: Parts: Brick, Modified* 6 30552Light Bluish Gray Hinge Cylinder 1 x 2 Locking with 1 Finger and Axle Hole on Ends with Slots Catalog: Parts: Hinge* 2 64567Light Bluish Gray Minifigure, Weapon Lightsaber Hilt Straight Catalog: Parts: Minifigure, Weapon* 6 3023Light Bluish Gray Plate 1 x 2 Catalog: Parts: Plate* 2 4085dLight Bluish Gray Plate, Modified 1 x 1 with Open O Clip Thick (Vertical Grip) Catalog: Parts: Plate, Modified* 1 3839bLight Bluish Gray Plate, Modified 1 x 2 with Bar Handles - Flat Ends, Low Attachment Catalog: Parts: Plate, Modified* 1 18649Light Bluish Gray Plate, Modified 1 x 2 with Bar Handles on Ends Catalog: Parts: Plate, Modified* 1 63868Light Bluish Gray Plate, Modified 1 x 2 with Clip on End (Horizontal Grip) Catalog: Parts: Plate, Modified* 1 11476Light Bluish Gray Plate, Modified 1 x 2 with Clip on Side (Horizontal Grip) Catalog: Parts: Plate, Modified* 1 4697bLight Bluish Gray Pneumatic T Piece Second Version (T Bar with Ball in Center) Catalog: Parts: Pneumatic* 1 11477Light Bluish Gray Slope, Curved 2 x 1 x 2/3 Catalog: Parts: Slope, Curved* 1 24201Light Bluish Gray Slope, Curved 2 x 1 x 2/3 Inverted Catalog: Parts: Slope, Curved* 3 4265cLight Bluish Gray Technic Bush 1/2 Smooth Catalog: Parts: Technic* 1 4185Light Bluish Gray Technic Wedge Belt Wheel (Pulley) Catalog: Parts: Wheel* 1 6553Light Bluish Gray Technic, Axle 2L with Reverser Handle Axle Connector Catalog: Parts: Technic, Axle* 1 4519Light Bluish Gray Technic, Axle 3L Catalog: Parts: Technic, Axle* 1 32073Light Bluish Gray Technic, Axle 5L Catalog: Parts: Technic, Axle* 1 32034Light Bluish Gray Technic, Axle and Pin Connector Angled #2 - 180 degrees Catalog: Parts: Technic, Connector* 4 32064Light Bluish Gray Technic, Brick 1 x 2 with Axle Hole Catalog: Parts: Technic, Brick* 2 60483Light Bluish Gray Technic, Liftarm Thick 1 x 2 - Axle Hole Catalog: Parts: Technic, Liftarm* 2 61184Light Bluish Gray Technic, Pin 1/2 with 2L Bar Extension (Flick Missile) Catalog: Parts: Technic, Pin* 1 4274Light Bluish Gray Technic, Pin 1/2 without Friction Ridges Catalog: Parts: Technic, Pin* 4 32138Light Bluish Gray Technic, Pin Double with Axle Hole Catalog: Parts: Technic, Pin* 2 3673Light Bluish Gray Technic, Pin without Friction Ridges Catalog: Parts: Technic, Pin* 1 54383Light Bluish Gray Wedge, Plate 6 x 3 Right Catalog: Parts: Wedge, Plate* 1 87580Pearl Gold Plate, Modified 2 x 2 with Groove and 1 Stud in Center (Jumper) Catalog: Parts: Plate, Modified* 1 3004Red Brick 1 x 2 Catalog: Parts: Brick* 1 3666Red Plate 1 x 6 Catalog: Parts: Plate* 1 11477Red Slope, Curved 2 x 1 x 2/3 Catalog: Parts: Slope, Curved* 4 32062Red Technic, Axle 2L Notched Catalog: Parts: Technic, Axle* 2 41677Red Technic, Liftarm Thin 1 x 2 - Axle Holes Catalog: Parts: Technic, Liftarm* 3 3069Red Tile 1 x 2 Catalog: Parts: Tile* 1 6636Red Tile 1 x 6 Catalog: Parts: Tile* 3 27263Red Tile, Modified Facet 2 x 2 Catalog: Parts: Tile, Modified* 1 43723Red Wedge, Plate 3 x 2 Left Catalog: Parts: Wedge, Plate* 1 43722Red Wedge, Plate 3 x 2 Right Catalog: Parts: Wedge, Plate* 2 15462Reddish Brown Technic, Axle 5L with Stop Catalog: Parts: Technic, Axle* 1 3749Tan Technic, Axle 1L with Pin without Friction Ridges Catalog: Parts: Technic, Axle* 1 3062Trans-Light Blue Brick, Round 1 x 1 Catalog: Parts: Brick, Round* 2 4740Trans-Light Blue Dish 2 x 2 Inverted (Radar) Catalog: Parts: Dish* 8 4073Trans-Light Blue Plate, Round 1 x 1 Catalog: Parts: Plate, Round* 12 4073Trans-Red Plate, Round 1 x 1 Catalog: Parts: Plate, RoundMinifigures:* 1 sw0940 (Inv)Enfys Nest Catalog: Minifigures: Star Wars: Star Wars Solo* 1 sw0941 (Inv)Tobias Beckett Catalog: Minifigures: Star Wars: Star Wars Solo* 1 sw0942 (Inv)Weazel Catalog: Minifigures: Star Wars: Star Wars SoloExtra Items:Parts:* 1 4592c02 (Inv)Black Antenna Small Base with Black Lever (4592 / 4593) Catalog: Parts: Antenna* 1 11253Black Minifigure Footgear Roller Skate Catalog: Parts: Minifigure, Body Wear* 1 3024Black Plate 1 x 1 Catalog: Parts: Plate* 1 54200Black Slope 30 1 x 1 x 2/3 Catalog: Parts: Slope* 1 25269Black Tile, Round 1 x 1 Quarter Catalog: Parts: Tile, Round* 1 4274Blue Technic, Pin 1/2 without Friction Ridges Catalog: Parts: Technic, Pin* 1 4073Dark Bluish Gray Plate, Round 1 x 1 Catalog: Parts: Plate, Round* 1 15392Dark Bluish Gray Projectile Launcher Part, Trigger for Gun, Mini Blaster / Shooter Catalog: Parts: Projectile Launcher* 1 18041Flat Silver Minifigure, Weapon Harpoon, Smooth Shaft Catalog: Parts: Minifigure, Weapon* 1 29109Flat Silver Minifigure, Weapon Machete Catalog: Parts: Minifigure, Weapon* 1 4073Flat Silver Plate, Round 1 x 1 Catalog: Parts: Plate, Round* 1 48729bLight Bluish Gray Bar 1L with Clip Mechanical Claw - Cut Edges and Hole on Side Catalog: Parts: Bar* 1 87994Light Bluish Gray Bar 3L (Bar Arrow) Catalog: Parts: Bar* 1 64567Light Bluish Gray Minifigure, Weapon Lightsaber Hilt Straight Catalog: Parts: Minifigure, Weapon* 1 4697bLight Bluish Gray Pneumatic T Piece Second Version (T Bar with Ball in Center) Catalog: Parts: Pneumatic* 1 4265cLight Bluish Gray Technic Bush 1/2 Smooth Catalog: Parts: Technic* 1 4274Light Bluish Gray Technic, Pin 1/2 without Friction Ridges Catalog: Parts: Technic, Pin* 1 3673Light Bluish Gray Technic, Pin without Friction Ridges Catalog: Parts: Technic, Pin* 1 4073Trans-Light Blue Plate, Round 1 x 1 Catalog: Parts: Plate, Round* 1 4073Trans-Red Plate, Round 1 x 1 Catalog: Parts: Plate, RoundCounterparts:Parts:* 4 15403c01 (Inv)Black Projectile Launcher, 1 x 2 Mini Blaster / Shooter with Dark Bluish Gray Trigger (15403 / 15392) Catalog: Parts: Projectile Launcher* 3 2335pb179Dark Tan Flag 2 x 2 Square with Black Curved Stripes on Red Background and Hull Plates Pattern on Both Sides (Stickers) - Set 75215 Catalog: Parts: Flag, Decorated* 3 44676pb039Dark Tan Flag 2 x 2 Trapezoid with Black Curved Stripes on Red Background and Hull Plates Pattern on Both Sides (Stickers) - Set 75215 Catalog: Parts: Flag, Decorated* 1 6636pb163Red Tile 1 x 6 with Black Curved Stripes Pattern (Sticker) - Set 75215 Catalog: Parts: Tile, DecoratedSummary: Type Unique Lots Total Qty Regular Items: Parts 136 342 Minifigures 3 3 Extra Items: Parts 20 20 Counterparts: Parts 4 11 Source:Sealed Set Contents

A conventional indexable end mill requires this drilled start hole because the tool is not able to execute a straight Z-axis move into the material. The only other way to enter the material with this type of cutter is a ramp-in entry, which typically calls for CAM software. However, with a copy mill, this step can be avoided. Plunging can be programmed into the control's canned pocketing cycle without concern for the tool's entry. This freedom to plunge is particularly helpful in more complex cavity roughing or surface roughing routines, where a CAM package may interject numerous plunge points in order to complete the roughing tool path. With copy mill cutting tools, these plunge points are no longer a concern.

Disclaimer: BrickLink does not guarantee an inventory to be correct and therefore an inventory should be only used as a guide.

In other words, helical interpolation in this example delivers an 87 percent reduction in cycle time. It also eliminates one tool.

The shop pushes an indexable 1.25" diameter drill through the part first, which takes only 1.5 minutes. The next step, requiring much more time, is to run a circular interpolation canned cycle using an indexable 1" diameter end mill. Parameters for this tool are 0.1" depth of cut, 0.7" width of cut, speed 2,300 rpm and feed rate 25 ipm. The total cycle time for circular interpolation is 35 to 45 minutes, so the total cycle time for two tools together can be assumed to be about 45 minutes.

With the right tooling, even machine tools with only 10 or 15 hp are capable of competitive metal removal, resulting in fewer setups and greater flexibility in shop floor scheduling.

A 6" by 12" pocket, 1.25" deep, was cut on a 15 hp, 40 taper machining center using the copy milling cutter shown. Parameters were 2,200 rpm, 250 ipm and 0.035" depth. Cycle time was 8 minutes, 18 seconds.

A copy mill can't take the place of a drill; the surface area engaged is too large to continue this way much beyond the desired depth of cut for milling. However, the ability to plunge during milling removes a common machining headache: the need to drill a start hole prior to roughing.

Fig. 1 – Round inserts cut more efficiently at light depths. A light depth of cut decreases the chip thickness and therefore decreases the horsepower demand.

Larger-diameter hole making can be quick and easy when a copy mill is used in combination with helical interpolation. This technique resembles thread milling in that all three axes (X, Y and Z) are in motion simultaneously. It differs from thread milling in that the tool is introduced into the material without a start hole of any kind. The tool simply is positioned at the inside diameter of the hole to begin its helix from there, achieving complete material removal from the hole by ramping down to the final depth.

But in this scenario, toolholding rigidity is important. Stub-length end mill holders or shell mill holders are highly recommended.

One alternative that can provide a smoother cut, in addition to many expanded capabilities, is the copy mill. "Button cutter" is another name for this type of tool.

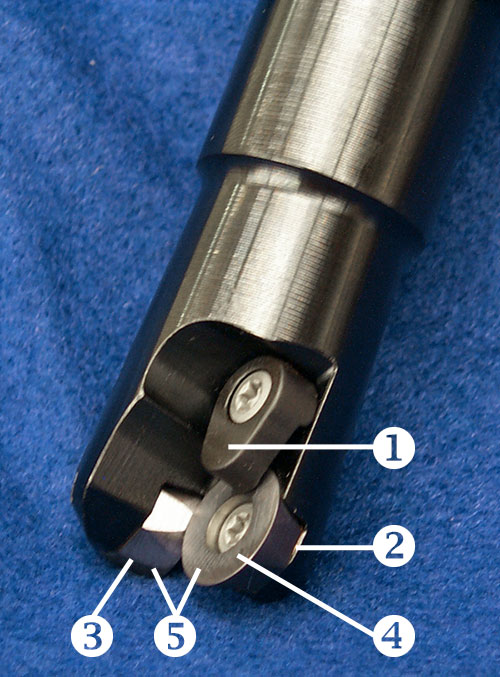

The anatomy of this copy end mill includes the following features: (1) top clamp for secure insert mounting; (2) positive axial rake for supporting the cutting edge; (3) insert facets for positive locking; (4) ground inserts for accuracy in finish cuts; and (5) adjacent inserts to provide plunging capability.

The 4" dia. hole shown here was machined in 4140 steel using a 1" diameter copy mill at 4,000 rpm, 200 ipm and 0.035" depth of cut.

The diameter of each pass equals the difference between the 4" hole diameter and the 2" tool diameter, or 2". Total distance traveled by the tool equals the product of 55 passes multiplied by 6.28" per pass (the circumference of a 2" diameter circle), or 345". At 61 ipm, the time to feed this distance is about 5.5 minutes.

Hygrotus (869) inventoried this Set on Jul 16, 2018, inventory last updated on Mar 8, 2024. axaday (7552) confirmed accuracy of this inventory on Jul 15, 2019. (source: Sealed Set Contents)Links Related to this Inventory:View a printer-friendly version of this page [with temporary checkboxes]Show Part Color Codes (?)Confirm Accuracy of this inventory if you are a registered Inventories Verifier (?)Upload an Image in the specific color if you have one and the one in the above listing is not available.Fill out an Inventory Change Request (?) [ Show Inv Item IDs ] if you found an error in this inventory.View a log of completed changes made to this inventory.See explanation on what Regular, Extra, Counterpart and Alternate means.Disclaimer: BrickLink does not guarantee an inventory to be correct and therefore an inventory should be only used as a guide.

Finally, look for tools providing maximum support for the cutting edge, particularly if high feed rate is the goal. Copy mill cutters using negative axial rake (tipping the insert down toward the workpiece) can cut well using conservative parameters but fall short during more aggressive metal removal. Inherent in the design is a lack of support for the primary area of force, which is right at the cutting edge. (See Figure 2.) Copy mill cutters using positive axial rake provide much better cutting edge support because the carbide behind the cutting edge is closer to being parallel with the cut. Positioning the carbide in this way lets the end user take advantage of the carbide's ability to absorb high compressive forces.

Links Related to this Inventory:View a printer-friendly version of this page [with temporary checkboxes]Show Part Color Codes (?)Confirm Accuracy of this inventory if you are a registered Inventories Verifier (?)Upload an Image in the specific color if you have one and the one in the above listing is not available.Fill out an Inventory Change Request (?) [ Show Inv Item IDs ] if you found an error in this inventory.View a log of completed changes made to this inventory.See explanation on what Regular, Extra, Counterpart and Alternate means.Disclaimer: BrickLink does not guarantee an inventory to be correct and therefore an inventory should be only used as a guide.

Another important feature is positive locking in the insert seat. Many button cutters use inexpensive molded inserts that have round sides, providing no radial locking for the insert. Tangential cutting forces on an insert such as this may cause the insert screw to lose torque. More rigid copy mills address this problem with locking surfaces on the sides of the inserts — locating flats that mate with matching flats on the cutter body, leaving little chance for movement.

0086-813-8127573

0086-813-8127573