Drill Bits and Drill Bit Sets - machinist drill bit set

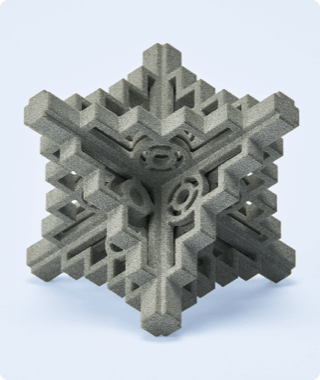

Our industrial 3D printers and professional operators will produce your prototypes and end-use parts with the highest quality.

Woodcnc printing services

We manufacture rapid cost-effective prototypes and low-volume production orders for a variety of industries and applications, like functional prototypes & production parts, automotive, aerospace, electrical appliances, household appliances, consumer electronics, etc. High-precision 3D printing from digital design to physical objects makes the end product practical and marketable.

CNCservice near me

Workholding refers to the process of securing a workpiece in place during a manufacturing operation. This is typically done using specialized tools or fixtures that are designed to hold the workpiece securely and accurately, allowing for precise machining or other operations to be performed.

JLC3DP 3D printing service allows me to use modern and advanced 3D-printing technologies like MJF or SLS that I couldn't use otherwise as a hobbyist. The pricing is affordable, and I use it for functional parts prototypes.

Best onlineCNCservice

I have been using the JLC3DP services across the years with a high trust and I didn't hesitated to try their 3D printing service, consequently it shorten the way to get my products fully ready to go from one centered supply source. Their team is knowledgeable and supportive in a way that you could easily get assisted.

JLC3DP SLM 3D printing service is so speedy and easy-to-use. Now we can use metal 3D printing not only for making parts for business, but also for hobby because they also offer an affordable price. It's a game changer!

Metalcnc printing services

At Berkness Company, we understand the importance of workholding in the manufacturing industry, which is why we offer a wide range of workholding solutions to meet the needs of our customers. Our team of experienced engineers and technicians can help you select the right workholding tools and equipment for your specific application, whether you need a simple clamp or a complex fixture.

One of the most significant benefits of workholding is that it allows manufacturers to increase their productivity and efficiency by reducing the time and effort required to set up and adjust workpieces. With the right workholding tools and techniques, manufacturers can achieve faster cycle times, higher accuracy, and better repeatability, which can translate into significant cost savings and improved quality.

Workholding is a crucial service performed in the manufacturing industry that involves the use of specialized tools and equipment to hold and secure workpieces during machining operations. The primary goal of workholding is to ensure that the workpiece remains stable and in the correct position throughout the machining process, which is essential for achieving accurate and precise results. Workholding devices can range from simple clamps and vises to more complex fixtures and chucks, depending on the size, shape, and complexity of the workpiece.

CustomCNCmachining near me

We also offer custom workholding solutions that are designed and built to your exact specifications, ensuring that you get the precise results you need for your manufacturing process. Our workholding services are backed by our commitment to quality, reliability, and customer satisfaction, and we are always available to provide support and assistance whenever you need it.

CNCmachining service

There are many different types of workholding devices used in manufacturing, including clamps, vises, chucks, collets, and fixtures. Each type of device is designed for a specific application and can be used to hold a workpiece in place during a variety of machining or other manufacturing operations.

Cnc printing servicesnear me

JLC3DP 3D printing service covers a worldwide delivery, we will ship parts to your doors directly from our 3D printing factory.

If you are interested in learning more about our workholding services or would like to discuss your specific needs with one of our experts, please visit our Contact Us page on the Berkness Company website. We look forward to hearing from you and helping you achieve your manufacturing goals with our high-quality workholding solutions.

Experience precision manufacturing with Berkness Company. As a one-stop-shop for CNC Swiss turning and tool and cutter grinding, we pride ourselves on delivering quality products and services that exceed customer expectations. We're committed to providing innovative solutions, fast turnaround times, and competitive pricing. Experience the difference today.

Capabilities and quality that they are offering cannot ever be reached at home. Especially complex materials, like PA12-HP nylon. I’ve ordered good amount of parts and all I can say is that it’s truly amazing! Service is great for large quantities as well as for small first order prototypes.

Workholding is a critical aspect of manufacturing, as it directly impacts the quality and accuracy of the finished product. Proper workholding ensures that the workpiece remains securely in place during machining or other operations, which helps to prevent errors and defects. Additionally, effective workholding can help to improve production efficiency and reduce costs by minimizing the need for rework or scrap.

0086-813-8127573

0086-813-8127573