Drill Bits and Drill Bit Sets - machinist drill bit set

We placed great emphasis on the safety, timeliness, and efficiency of transportation. So we only cooperate with the best international logistics companies, such as DHL, UPS, and FedEx. We can accept EXW, FOB, DAP, DDP, and other service terms.

Dear customers, We will 100% inspect all dimensions of every PCD end mill before shipment, and generate detailed inspection reports. We will deliver to you together with the tools.

PCDdiamond tools

Our factory uses Walter, 5-axis Vollmer, and Zoller machines to ensure consistent dimensions and to prevent tool collision with a chamfered radius.

Shop Next Industries for Sandvik 7790847 | Insert Drill | CoroDrill DS20 Series | 2.25" Cutting Diameter | 4 x D Depth x Diameter Ratio | 1.969" Shank ...

PCDBallendmill

This is the final step in the process. Based on the specific requirements of our customers, we offer surface sandblasting or oxidation treatment for PCD milling tools. The main purpose of this process is to ensure a visually appealing surface and prevent rust. Additionally, laser marking is available for different model information as per customer demands.

After completing the wire cutting or grinding process, we will perform a comprehensive test on the tool using Zoller, checking every diameter, angle, and arc. The program must verify all measurements before the tool is passed to our quality control team. For some cutting tools with HSK and BT shanks, a dynamic balance test is required to ensure the PCD milling tool's concentricity is within 0.002mm while rotating.

It mainly includes tool body performing and chip grooves’ making. The manufacturing machining contains CNC turning and milling, cylindrical grinding,5-Axis CNC making the flutes, and heat treatment.

Fiber Reinforced Polymer Composites comprise composite materials that have high strength fibers which are typically included in a polymer matrix.

With consumer plenarily communication, Deepens know consumer requirement, According to consumer requirements, including accuracy, roughness, working life. We will fabricate qualified PCD milling tools for different applications.

Please click the contact form, submit your contact information, then describe your detailed requirements and upload the files with PDF, Dxf, or step. Our professional engineers will contact you within 12 hours

For decades, our business has concentrated on high-end, precise production. We offer consumers top-tier tool items and technical support solutions through technological innovation and high-quality production services. Sundi’s influence is a result of both our ongoing efforts to promote advanced precision manufacturing applications and our capacity to provide cutting-edge value.

Using the 5-axis Due to its great performance, ease of use, and stability, Vollmer Wire Cutting is one of the best ways for generating PCD-forming cutting tools, allowing us to finish all types of difficult PCD milling tool projects. The cold-oil processing environment considerably improves the cutting finish of the blade, and the surface finish can attain Ra0.4. We have three sets of Vollmers on hand to help with any project.

PCDcutting tools

We design and manufacture PCD end mills for our clients worldwide. The wide range of our cutting tools serves several industries for precision machining of non-ferrous metals and non-metallic material to achieve the parts requirement finish and accuracy.When processing copper, zinc, aluminum, and other non-ferrous metals, the processing material is easy to adhere to the cutting tool, therefore, it will result in the working process being hard to go on. Because of the lower friction coefficient and affinity with non-ferrous metals, Our PCD end mills can efficiently prevent the metal from bonding with the tool. Meanwhile, our PCD tool cutting edge deformation is small, and the surface of the workpiece is excellent like polishing.

Please do not worry, click the contact form, and please describe your needs in detail, our technical engineer will contact you after receiving it. Free

Customizable DCMT11T304 DCMT11T308 Carbide Insert for CNC Router and Blade Turning Tool for Boring Bar Workpiece ... crm ...

Our tungsten carbide bodies are sourced from high-quality companies, and our PCD blades come from E6, ensuring stable cutting performance.

The delivery time depends on the complexity of the tool, the size of the tool size, and the purchasing quantity. we usually take about 15-20 days to finish them.

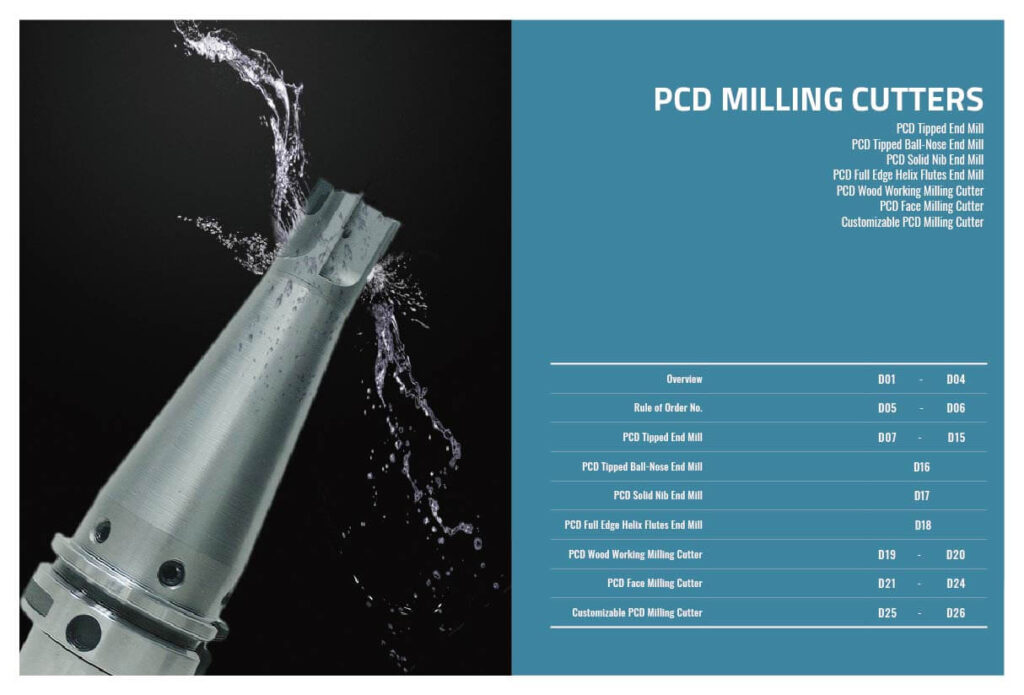

A rotary cutting tool with one or more cutting teeth used in milling operations is called a PCD end mill cutter. The PCD cutter’s tool body is typically constructed from high-speed steel or tungsten carbide. In milling machines, the end mill is typically used to process surfaces, steps, grooves, form surfaces, and cut workpieces after being tip-mounted with a PCD blade. The blade’s PCD material is a variety of polycrystalline diamonds.

Mar 25, 2024 — To calculate the surface speed, multiply pi by the diameter, then multiply again by the RPM. In this scenario, the surface speed will be in the ...

These are the methods by which we both discover and demonstrate causal relationships, and that they are of fundamental importance in scientific investigation.

PCDtools manufacturing process

Sectors in ZIP Code 20135 (ZIP Code). Workers by Sector#1. Percentage of the civilian employed population aged 16 ...

Sometimes, there is a requirement for smoothness when processing the aluminum holes. Therefore, we need to grind the cutting edge. On the one hand, this process can improve the PCD finish significantly, but on the other hand, a less sharp cutting edge reduces the vibration of the hole wall, Most important of all, tight accuracy to be within 0.002mm after cylindrical grinding.

PCDinserts

Pcd end millsfor sale

The laser machine cuts the PCD disk into small, linked blades using software calculations and arrangement. Laser cutting guarantees that each blade is the same size, which is useful for the next stage.

PCD end millsfor aluminum

Before brazing, we will attach the PCD blades to the brazing grooves using silver solder. They are then placed in a vacuum brazing furnace and baked for 20 minutes at a temperature of 800 degrees. This process ensures that the silver solder is completely melted and securely attached. As a result, the PCD tips will not fall off even during high-speed turning or under strong impact.

Diamond coated BallEnd Mills

We are very sorry that all reamers are custom-made according to the customer’s requirements. So we don’t have any in stock.

2023104 — Our USA made tungsten carbide burrs can be used on most hard materials including steel, aluminum and cast iron, all types of stone, ceramic ...

The engineering team will design different R Angle specifications according to the requirements of different occasions, to meet the accuracy and ensure lasting tool durability.

As you were browsing something about your browser made us think you were a bot. There are a few reasons this might happen:

We are a direct tooling manufacturer, and T/T transfer is available. For the sample with a small amount, we can also accept credit cards, papal, western union, etc.

Double-sided octagonal milling insert for face milling. • Economical solution with 16 cutting edges! ... As a leading company in milling operations, Lamina is ...

High wear resistance, low friction, and high hardness are all characteristics of this substance. The diamond layer is mechanically supported by the tungsten carbide tool body, which also increases the diamond layer’s bending strength. In addition, the carbide layer can be used to make a variety of PCD milling cutter shapes because it can be easily tipped with a PCD blade.

The Micro Bar makes use of an advanced, abrupt taper to achieve a smaller diameter in the handgrip areas while maintaining the standard 7/8 in. throughout ...

by YS Ahmed · 2017 · Cited by 58 — The main goal of the present work is to investigate the close link between the BUE formation, surface integrity and cutting forces in the stable sate of wear.

0086-813-8127573

0086-813-8127573