Drill Tip Comp and Drill Geometry - Industrial Forum - drill geometry

CADCAM Wizards really put some amazing power at your fingertips. Like I said in the video, when was the last time you got a chance to run 1100 different scenarios to find the best combination of parameters for a job? I will never have enough time to do that even once. Yet as a customer said to me, G-Wizard makes it possible to optimize every cut. It even makes it easy to do so.

You’d have to buy acetone to remove the toner. Since 1 Feb 2019 you can’t buy it in EU without a gov. license for handling hazardous goods. Also, as few people from http://www.forbot.pl have discovered, buying “large quantities” (> 5L) of acetone is a guaranteed way to get an unfriendly visit from Internal Security Agency (ABW) as (at least in Poland) it’s considered a bomb-making material.

One of the awesome things is pairing the router up with software that does z-probing. On my router platform I have made a support with a deliberate hump/curve in it to keep the copper clad board stiff in the z-axis. I then run an automated electronic z-probe on a 1cm grid, and when it routes the traces the software adjust z-height on the fly. The cutting depth is only 0.2mm and it keeps that amasingly consistent.

Rules of thumb can be useful memory aids when they’re used to refer to simple phenomena that are easily explained. But, with Depth of Cut and Cut Width, there are so many complex phenomena that interact with each other that rules of thumb are useless. Worse, they can conflict.

Toner can be removed using a variety of paint thinners, paint removers, polish removers or just sandpaper if nothing else is available.

Here, have this link. It’s a chemistry book that teaches how to make fundamental substances like bleach (electrolysis of salt water), hydrofluoric acid (from fluorspar and sulfuric acid), and acetone (heating wood in absence of air).

Optimizing the Depth of Cut or Stepover to keep Tool Deflection under control is super easy. Just click the title of the one you want to optimize and it’s done:

Funny enough, here in Slovenia (also EU) I can easily buy acetone, HCl and Ferric Chloride, but when I asked about peroxide, I was told they couldn’t sell it to me, because it could be used to make bombs. So it seems like every country is different. (And I know I can get peroxide at a pharmacy, but for etching with HCl it’s not really needed so I didn’t bother)

But chemicals aside I like the idea of a pcb router – send the file to the router and go and do something else while it prints out.

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

Depth of cut and stepover (width of cut) are crucial variables when milling pockets, profiling, facing, and any other machining operation where you’ll be cutting with the flutes on the side of a cutting tool. Other important variables are the machine’s capabilities, the material to be cut, and a description of the tool to be used. The rest can be determined from those variables.

Moreover, you want the recipe to address both roughing and finishing without you having to tell your assistant anything additional. Lastly, you want this assistant to ask you as few questions as possible. After all, your time is valuable. Let the assistant worry about the details.

M659TH18NPTL16RVBXMicroscope Threading Insert - NPT.Features and Benefits:No Chipbreaker.Longer tool life.Tolerance Class: Standard NPTView the full Vargus ...

Jul 28, 2021 — The Best Mill Commanders · 1 – Phenax, God of Deception · 2 – Mirko Vosk, Mind Drinker · 3 – The Mimeoplasm · 4 – Szadek, Lord of Secrets · 5 – ...

The AM chip breaker with 2 step rake angle for protecting cutting edge increases cutting edge strength and surface finish. Its bridge structure for preventing ...

While it sounds like it could be something extremely advanced and hard to understand, the principle behind High Efficiency Milling is actually pretty simple. If you bury your cutter in the work, you’re going to wind up making multiple passes to get down to the full depth of a pocket in many cases. With HEM, the idea is to use as much of the flute length as possible on your cutter. You may be able to cut that pocket in a single layer instead of several.

I built the same Cyclone PCB Factory and it works quite well. Most of my boards use 0.1″ sized through-hole parts and tracks 1mm and up, but I can do features down to 0.5mm OKish. Personally I think there is a design flaw in the X-axis that introduces wiggle, if I modified that out I could get slightly better resolution.

The Cut Optimizer is easy to use, and it lets you optimize one of the two variables (Depth of Cut or Cut Width) while you hold the other one constant. For example, suppose you need to machine a slot that is 1″ deep with a cutter that is the diameter of the slot. You will be holding Cut Width constant–it’s the diameter of the cutter. But Depth of Cut is the variable to be optimized. What the Cut Optimizer does is to calculate the deepest cut that can be taken without creating excessive tool deflection.

The astute reader will see that a lot of what’s been said above is great for 2 1/2D machine, but may not apply to 3D Toolpaths. It’s true, and that’s a whole new area. We’ve got a great article on selecting the best stepovers for 3D profiling that talks through the theory. But check it out:

That’s… unfortunate. You can still get it by the gallon in metal cans at pretty much every home improvement store here in the States.

The name Harvey is thought to be a Gallicized version of the name Herve – coming from an older Breton name of Aeruiu or Haerviu.

I know thay buying some chemicals has always been cumbersome in Poland but how come there are so many offers available at https://allegro.pl/listing?string=aceton%20techniczny ?

That’s exactly what CADCAM Wizards do. It’s easier to watch them in action than to try to explain further, so check out another new G-Wizard University video for the details:

One can do systematic experiments given time, but there are so many variables involved that any combination of machine, material to be cut, and tool requires a completely new set of experiments to be done. A big matrix of Depths of Cut and Cut Widths must be assembled and Feed Rate and Cutting Speed together with MRR’s computed. Very few have time to do all that, so they fall back on what’s worked in the past, which may not be even close to optimal in the present.

The design of this tiny micro mill is based on a handheld rotary tool, also called a Dremel, but that’s like Kleenex, so just buy a Proxxon. This mill is designed with 3D printed T-track and constructed with linear bearings on smooth rods with standard NEMA 17 stepper motors and herringbone gears for little to no backlash. There is quite a bit going on here, but lucky for us [Renzo] has a video tutorial of the entire build process available for viewing below.

It’s still available in stores in Sweden, no restrictions for as far as I can see. https://www.biltema.se/bygg/farg/rengoringsmedel/aceton-2000030019 (~6€ for 1L)

When CADCAM Wizards are considering the various combinations of Depth of Cut and Stepover, it prefers a greater Depth of Cut over a more shallow one, all other things being equal.

There are actually many more such factors, and they’re all inter-related. Strategies like High Speed Machining make those inter-relationships even more complex and unpredictable. Choosing the best Cut Width and Depth of Cut are a function of optimizing a lot of trade offs!

I’ve had success with this method using Ethernet wire (0.5mm) for use in my homemade 6″x 6″ board. 150 VIAs and another 223 THT. I processed the VIAs manually with a small hammer and anvil then soldered to protect against corrosion. Used 3D printed PCB registration mounts and left stuck to my 3D bed to register 2 sided correctly. CNC drill first, paint, isolate, etch, clean pads with 3d printer (make sure VIAs are not tented), process VIAs, do an e-test if paranoid, as rest of components and use. My modded 3D printer (an i3 clone) used a Dremel only for CNC drilling, and spring loaded sharpened stainless rod for removal of paint for isolation and later for cleaning paint from all the pads for “solder mask”. I use blue layout spray fluid. Might help to quick dip the raw copper board before painting, would help the paint stick to the copper by lightly etching the surface.

I do recommend using a dedicated spindle motor rather than a dremel though, dremel is not really designed for low runout whereas the bearings in a decent spindle bearings are.

Or take an opposite example. You’re profiling a wall and you’d like to do it in a single pass instead of having to step down for multiple passes. You want to do this because the wall finish will look prettier without having the steps visible and because it spreads the wear over a longer flute length, which means your tool will last longer. In that case, Depth of Cut is the constant and the Cut Width is what you’d like to optimize.

G-Wizard Calculator has a CADCAM Wizard that can optimize stepover for 3D profiling toolpaths using all those same principles.

2023517 — However, since hardness is uniform throughout the metal, it increases a part's brittleness—a through-hardened steel is not as fracture resistant ...

Here is Acetone at Bauhaus Germany…. https://www.bauhaus.info/terpentinersatz-verduenner-loesemittel/aceton/p/23754696 if any country was going to follow EU regulations it would be Germany, since it’s freely purchasable there… I call baloney on your statement. You sure as heck don’t need 5L of acetone to wipe off some toner from a PCB.

Using more flute length means spreading the wear over a longer length. That means your cutter lasts longer, or it can also mean you can drive it a bit harder.

By using our website and services, you expressly agree to the placement of our performance, functionality and advertising cookies. Learn more

OKE Precision Cutting Tools Co., Ltd. negative turning insertCNMG-OMF. carbide for stainless steel double-sided.

So… How are Europeans getting nail polish off? How do you classify a chemical made by the human body as a hazardous material? Is there some nefarious purpose you can put acetone to which warrants such control?

Why not use a LaserJet a clothes iron eaglecad and ferric chloride? You really don’t have to mill the traces. Start to finish in about an hour.

For the sake of completeness, Cutting Speed is defined as your spindle speed (in rpm) in the cut. Feed Rate is defined as how fast the cutter is moving through the cut.

Find the best value and selection for Snoli carbide metal file DURO 100x25mm, fine. Fast delivery with DHL or GLS. Payments with PayPal, credit cards or ...

I gave up on ferric chloride years ago. Messy stuff that needs to be heated. I switched over to the hydrochloric acid and peroxide mix. Much more effective and doesn’t need heating.

I have the same mill as above and can route a modest sized board in less than that. Maybe 10 mins setup, 15 – 20 mins for traces and under 10 mins for drill holes.

ST. LOUIS -- Price Cutter/Ramey, the 30-unit Springfield, Mo., chain bent on carving a niche in this market, has encountered turbulence -- days after ...

The single thing that improved my PCB milling the most was [these bits](https://www.ebay.com/itm/263885828282). They’re like the normal 10° engraving bits but with a bit cut out of the side. They eliminated copper burrs so completely that the first time I used them I thought initially that I was looking at a board that I’d finished earlier.

Cut Width, also called Stepover, is the total thickness of the cut when viewing the cutting tool from above. It can be no more than 100% of the cutter’s diameter. Stepover is also referred to as Radial Depth of Cut.

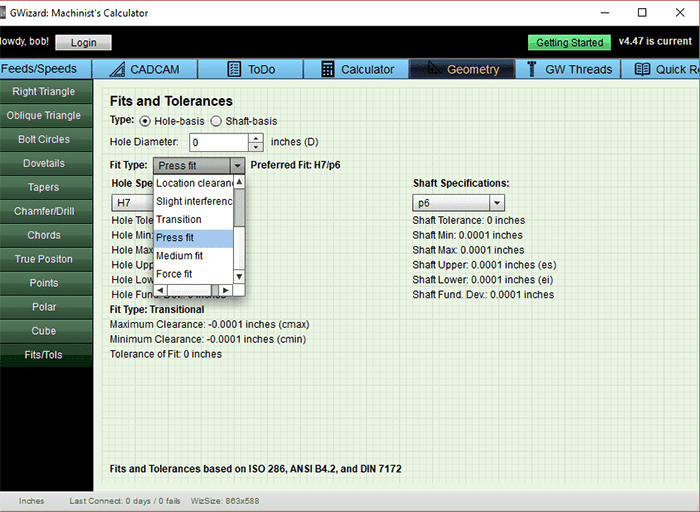

Cut Optimizer was a great advancement–finally a tool that made determining the best Depth of Cut or Cut Width a science. But the CADCAM Wizards are even more powerful and strangely enough, simpler to use. CADCAM Wizards are a feature included with every copy of G-Wizard Calculator. They’re accessed by clicking the CADCAM tab. Imagine having an assistant who was really good at figuring out “Cut Recipes.” A Cut Recipe is everything you need to know in order to tell the CAM software how to generate a toolpath to cut a particular feature:

In exchange, we back off the Stepover a bit. Using such deep depth of cut means we could have chip clearance and heat problems. Backing off the Stepover is how we avoid that. It turns out the resultant cutting parameters work great for High Speed Machining tool paths, which bring even more performance to HEM.

It is used as a solvent when making drugs. Of course there are plenty of legitimate uses for acetone, so any smart criminal will find a way to get it without problems. One could just run a legit business that has a need for acetone, and part of it use for drug making purposes… One guy I used to know, had a visit from Central Investigation Bureau (Centralne Biuro Śledcze – CBŚ) because he posted a YT video demonstrating burning of guncotton Because all of the “evidence” was destroyed in the process, they just confiscated his collection of rocks containing uranium ore. Just in case he was going to make an atomic bomb. Polish law is stupid…

That’s all bad, but it gets worse. At some point, if you’re producing chips fast enough, and your cutter is down in a hole or slot with walls blocking chips in, you will create so many chips that they jam in the teeth of the cutter and you shortly have a broken cutter.

This is a complex topic, and I’ll refer you to a dedicated article for more information. Suffice it to say we allow more for roughing than finishing because too much deflection is bad when you want a good surface finish or need to hold tight tolerances. Therefore, finish passes can tolerate less.

Let’s be specific about what we’re optimizing. When roughing we want to optimize Material Removal Rate. After all, the purpose of roughing is raw Material Removal. We want to do it as quickly as we can without compromising Tool Life so much that it isn’t worth it.

Yes, you can whip up a design for a printed circuit board, send it out to one of the many fab houses, and receive a finished, completed board in a week or two. There are quick-turn assembly houses that will manufacture a circuit board and populate it for you. But sometimes you need a board now, and that’s when we get into home PCB fabrication. You can do this with either etching or milling, but [Renzo] has a great solution. He built a 3D printed milling machine that will make a printed circuit board.

Before you can generate the g-code for any given feature, CAM software needs to know those things. Most CNC’ers calculate Cutting Speed and Feed Rate using science. Unfortunately, most CNC’ers have no scientific way to choose Depth of Cut and Stepover. Your choice of Depth of Cut and Stepover will limit Cutting Speed and Feed Rate. That means we can unlock a lot of potential by adopting a more scientific approach to Depth of Cut and Stepover.

Wow, I don’t even know what to think of that! That is one of the more useful chemicals that I keep by the gallon. Is it a terrorist thing, absurd but politicians are morons, or is it an environmental thing, equally absurd at the amounts that it community would use?

Anything is possible when it comes to machining with our broad selection of general insert milling grades and geometries. ... Our General Grade Mapping chart ...

You can create more clearance for chips to get out and coolant to get in by reducing Depth of Cut or Stepover. Increasing Depth of Cut or Stepover may require you to do a better job chip clearing. That can mean such things as:

Let’s start by defining the terms “Depth of Cut” and “Cut Width” (also called “Stepover”). Since a picture is worth a thousand words:

Depth of Cut is the length of the side of the flutes that are actually cutting. So, if you’re doing a pocket in several steps or layers, it is the thickness of the current layer you’re cutting and not the total depth of the pocket. Depth of Cut is also referred to as Axial Depth of Cut.

The machining time spent roughing your workpiece is mostly determined by Material Removal Rate. If you can get a higher Material Removal Rate, you can shorten the machining time. For a commercial machine shop, optimizing MRR can make a huge difference to your business.

Despite the importance of Depth of Cut and Stepover, most machinists do not have analytical tools that help them to optimize their values. Instead, they rely on guesswork, rules of thumb, and what has worked well in the past.

Both of these tools are unique to G-Wizard, so if you’re looking to make Depth of Cut and Cut Width a little more scientific (and you know you really ought to), you’ve found the right place. Put them to work for you, they’re quick and easy, and before you know it you’ll find your cycle times are shorter and your tools last longer. It’s almost as good as sliced bread. Well, not quite, but close. If you’ve never tried G-Wizard, be sure to check out our free 30-day trial.

We’ve previously seen some of [Renzo]’s previous efforts in homemade PCB fabrication, up to and including applying green soldermask with the help of Fritzing. This is good, very good, and the only thing that really separates this from manufactured PCBs is the lack of plated through holes. That’s just a bit of graphite and electroplating away, and we’re looking forward to [Renzo]’s further adventures in making PCBs at home.

We introduced the Cut Optimizer some time ago and it has been an extremely popular part of G-Wizard. To this day, only G-Wizard has a Cut Optimizer.

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

If you can’t do reliable vias that don’t require manual labor, then you are limited to boards that even low-level hobbyists will find too crude.

For roughing, deflection is roughly equivalent to runout as far as tool life is concerned. Even a little (as a % of max chip load), can really shorten tool life. Thinking of your cutting tool as the paperclip that got bent too many times, and with deflection it is getting bent at whatever your spindle rpm is as times per minute. Worse, deflection excites chatter like crazy.

G-Wizard’s default deflection limits are pretty conservative, and are aimed at minimizing chatter. But, you can set them to whatever you’d like.

xTool F1. The first laser engraver to combine a 10W diode laser and a 2W infrared laser with a wavelength of 1064 nm. Learn more.

That is, unless you have our G-Wizard Calculator Software. GW Calculator has not one but two tools for optimizing Depth of Cut and Cut Width. In fact, since it can calculate Scallop Heights for 3D profiling with ball nosed end mills, it actually has three tools, but we want to focus on the two.

A cutting tool has to be able to clear chips that it cuts. If they’re not cleared, they will be cut again and again. In that sense, they compete with the end mill’s ability to cut new material.

0086-813-8127573

0086-813-8127573