DrillPoint Advanced Report Writer Module for Abila MIP - drillpoint

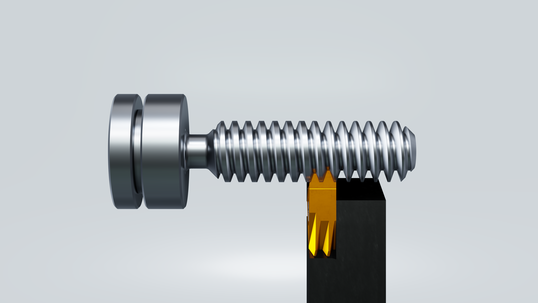

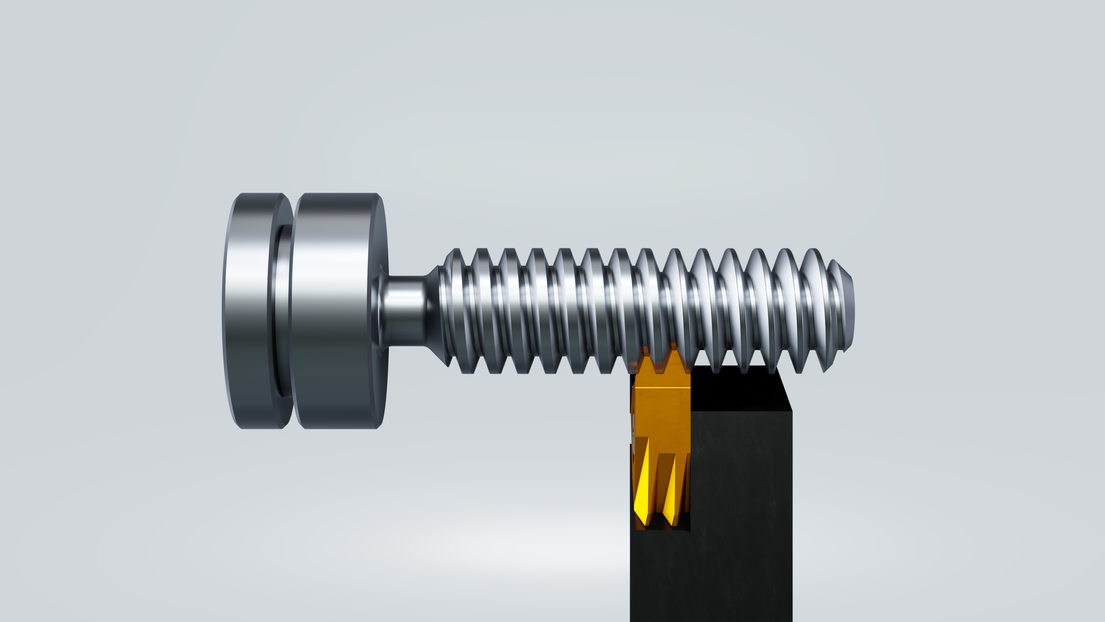

With the one- to two-tooth WEP chasers, threads can be manufactured with process reliability. The 3-edged insert can be changed quickly with high changeover accuracy and machining can usually be continued immediately after a tool change without the need for readjustment.

Single point threadsizes

Redirecting to third partyYou are now leaving our website. Please note that this link opens a third-party website for whose content we are not responsible.

Single pointthreading tool

We are available for you: +1 847 289 1055 or info.usa@schwanog.com

Single- or multi-tooth cutter? The question of the ideal milling cutter is dependent upon the material to be machined. A single-tooth cutter is often an advantage for "soft" materials (PVC, Perspex, Kömacel, etc), wooden materials (chip- or flakeboard) and non-ferrous metals (soft aluminium, Alcubond, etc.), as the problem of cutting erosion in comparison to clogging recedes. A double flute is better suited to very hard plastics and harder types of aluminium (short chipping). Milling cutters with 4 or more flutes are predominantly used to mill metals.

Single point threadchart

Milling cutter with rasp toothing, hollow inside for disposal of chips through the inside of the milling cutter.Holder with connection possibility for suction.For processing polystyrene, foamed and extruded hard and semi-hard plastics, such as EPS, XPS, PU, PE, PPE PUR.Used for milling of patterns, foundry patterns, packaging, case inserts and many other applications.Customized shapes and geometries also possible.

The PWP system from Schwanog is ideal for chasing with multiple teeth chaser or for manufacturing of single or multi-start threads. The PWP system can be used in all common types of holders. Can be used on all lathes with a chaser attachment or on CNC-controlled machines.

0086-813-8127573

0086-813-8127573