Engle Angle - angle spot hole corner

Users measure volume and area parameters, which are used to numerically determine the development of wear over a defined period of time. Based on this, types of wear such as flank wear, notch wear and plastic deformation can be determined. In conjunction with the automation interface "Automation Manager", measurement series for different tool types can be automatically configured, executed and organized.

Leading tool manufacturers worldwide use Bruker Alicona for quality assurance of tools and cutting edges. The product range includes fully automatic measuring solutions in production and comprehensive analysis modules including visualization. Measuring systems can be operated without prior knowledge of metrology. Taught-in measuring programs are started at the push of a button; the user has no influence on the measuring result. All measurements are high-resolution, traceable and repeatable.

Drill Cut Proreviews

Feb 22, 2023 — Down-milling is typically utilized for finishing operations, while up-milling is typically used for machining castings and forgings. 5. Other ...

Threading Inserts External & Internal Fully Ground with PVD Coating by Associated Production Tools.

Here is the answer for the crossword clue Opening for a lubricant, as in a drill last seen in Premier Sunday puzzle. We have found 40 possible answers for ...

TaeguTec Turning Line. January 2020 www.taegutec.com. Economical Double-Sided. Mini Size Inserts and Holders. Page 2. NPN. 2/13. TaeguTec Turning Line. New ...

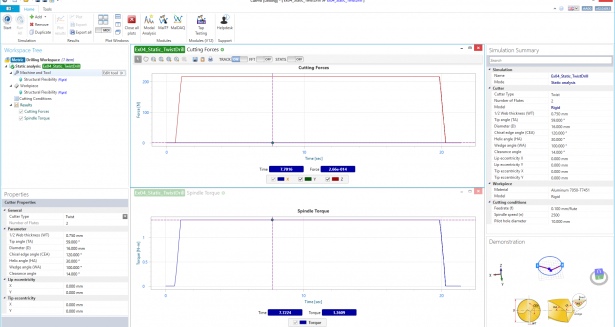

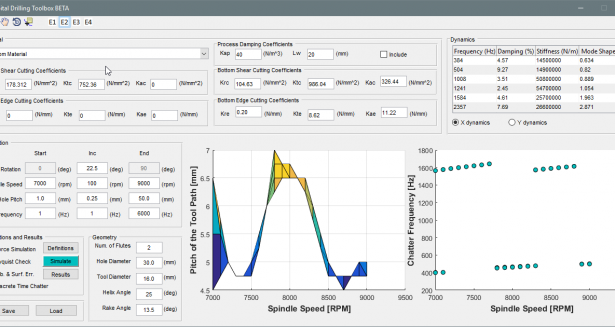

Developed at the internationally acclaimed Manufacturing Automation Laboratory (MAL) at The University of British Columbia, CUTPRO® provides high productivity solutions for the metal cutting world. MAL delivers strong technical follow-up support to its customers, and our twenty strong research engineers add new technologies to CUTPRO® every six months.

When quantifying the extent of plastic deformation, you can choose between "Depression" or "Impression". The software automatically detects which type is present if necessary. In addition to the evaluation at a single cutting plane position, you can also provide the mean and maximum value for the entire cutting edge.

Solid carbide drill bits are often made from tough tungsten, which makes them perfect for drilling. This premium material comes at a cost but is extremely ...

Drill Cut ProAmazon

Do you already measure the wear of your cutting tools, but you are repeatedly confronted with high measurement uncertainties?The Bruker Alicona Wear Measurement enables you to visualize and quantitatively assess wear on cutting edges based on high-resolution real 3D measurement data. In this process, wear is measured and analyzed over a certain period of time. The measurements are performed over the tool's lifetime repeatedly, either directly in the machine or separately.The software is an extension of the Bruker Alicona measuring systems for optical cutting edge measurement. Users automatically measure differential parameters and wear parameters according to ISO 8688 (Tool Life Testing in Milling), such as flank wear.

Double-Sided 80° Rhombic Inserts for Rough Turning on Stainless Steel and Soft Materials ... 80° Rhombic Inserts with a Single PCD Top Corner Tip and Positive ...

Parker Hannifin Salaries in Ravenna. How much do Parker Hannifin employees make? Glassdoor has salaries, wages, tips, bonuses, and hourly pay based upon ...

Positive angles (Figure a) result from counterclockwise rotation, and negative angles (Figure b) result from clockwise rotation. An angle with its initial side ...

CNC Machining with CNC Lathe and CNC Mill · Lathe capacity 12"OD 20" Length 2-15/15" thru hole · Threading ID and OD · Blind hole keyway broaching · Spindles ...

By adopting CUTPRO®, our advanced machining simulation software, you will achieve the highest possible material removal rates, extended tool life, and increased spindle life. You will be able to manufacture parts correctly at the very first trial, with reduced production cost, and significantly reduced machine down time.

Custom Router Bits. Custom Router Bits – Request for Quotes. We will be ... ROUTER, CNC OR MULTIPE):. POWER FEEDING : SHANK DIAMETER (1/4, 1/2 OR OTHER):.

0086-813-8127573

0086-813-8127573