Engle Angle - hole angle spot corner

Our broad selection of general turning grades and chipbreakers. Supporting inserts of different shapes, sizes and thicknesses.

These feeds and speeds are meant to be a starting point in finding the right parameters that work best for your setup. Feeds and speeds listed on this page have been tested to work with 2-flute, 1/8″ carbide end mills, the type of cutting tool that is most readily available in our store.

Check Stock/Price · Cross Reference · Datasheets\CAD · Find a Distributor ... Canada English · Canada Francais · USA English · Mexico Español · Mexico Português ...

Carbon fiber is the new fashion in home decoration, and various household products made of carbon fiber sheets can be found on the market today. Carbon fiber furniture is lightweight, durable, easy to clean, and has a high-end, high-tech look. Today, you can also find everything from phone cases and bathtubs to bow ties made of carbon fiber. These applications are limited only by imagination.

carbonfibre tensile strength (mpa)

Carbon fiber sheets are widely used in the aircraft industry. In fact, 30% of all carbon fiber produced is used in the aerospace industry. In addition to reducing the load on the aircraft, it is easier to maintain than metal and other traditional materials.

Good durability and corrosion resistance of carbon fiber board: acid, alkali, salt and atmospheric corrosion resistance, no need for regular maintenance. And it has a protective effect on the internal concrete structure, and can achieve the purpose of double reinforcement and repair.

Carbonfibre uses

Feed and speed choice depends on the material you are cutting, the type of tool you use, the speed of the router, the rigidity of the machine, and even the geometry of the model. In order to balance speed, finish quality, and precision you must account for bit deflection and material hardness.

If it is a big board the table saw will be hard to keep straight because you are moving a big piece of wood rather than a little router.

Carbon fiber board has high strength, good corrosion resistance, shock resistance and impact resistance: carbon fiber board has excellent physical and mechanical properties, the tensile strength is more than 6 times that of ordinary steel, the elastic modulus is better than steel, and it has excellent creep resistance Variable performance, corrosion resistance and shock resistance.

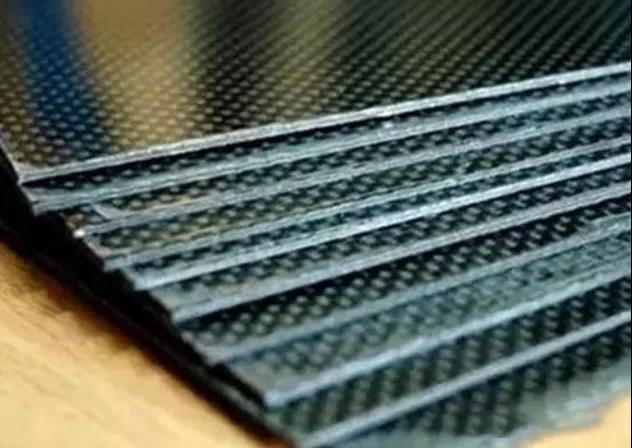

0°/90° Balanced Laminated Carbon Fiber Sheet: Excellent strength and stiffness in both longitudinal and transverse directions. They are textured on one side for easy bonding, while the other side has a choice of gloss, matt or textured finishes.

Depth of cut/ Step down: the amount of depth that the CNC machine removes with every cutting pass, defined in millimeters or inches.

Because carbon fiber is X-ray transparent, meaning it is transparent to X-rays and appears black in radiographic images, it is an ideal material for many medical applications. In addition to maintaining critical strength and stiffness under load, carbon fibers do not break even with repeated exposure to X-ray or gamma radiation. This makes carbon fiber sheets ideal for imaging device construction as well as prosthetics, and carbon fiber is even being studied to strengthen damaged cruciate ligaments.

Carbon fiberdensity

The construction of carbon fiber board is convenient and the construction quality is easy to guarantee: there is no wet operation, no need for large construction equipment, and no need for on-site fixed facilities. The length of the carbon fiber board can be arbitrarily cut, the construction is simple, and the construction period is short. The material does not need to be pre-processed, the process is convenient, and the plates are allowed to cross.

Another big use of carbon fiber in the aerospace industry is in tool design. Many of the tools used in aircraft production are very large, heavy and unwieldy. Using FEA calculations, in some cases, the weight of these tools can be reduced by as much as 75% when using carbon fiber to make tools.

Step over: the offset that is applied between the old cutting pass and the new one, usually defined as a percentage of the tool’s cutting diameter.

When cutting, the tool can be pushed away from where it should be since it’s not able to cut the material fast enough. Harder materials require a more rigid machine and longer milling times to steadily cut the material away. Sometimes it will take some trial and error to dial-in the right settings for your desired setup and materials.

Carbon fiber characteristicsand uses

Harvey & Company LLC · Compensation: $24/hour to start, after 6-months Research Analysts are eligible to receive an an increase to $25/hour and bonuses on ...

How iscarbon fibermade

Our custom cutting tools are designed with a round shank and spiral flutes for ease of use. The spiral flute design keeps the tool cutting freely by fast chip ...

Prepreg Carbon Fiber Sheet: Use when maximum strength or weight stiffness is required. These carbon fiber panels are made from unidirectional carbon fiber prepreg and/or twill carbon fiber prepreg. Manufactured in a heat press, these boards provide greater fiber volume, reduced voids and higher temperature performance. Prepreg carbon fiber sheets are available in standard modulus, high modulus and ultra-high modulus.

Anyone who's worked on a corporate trade show knows that a company booth needs to be lightweight, durable, and look better than everyone else. Once again, carbon fiber panels provided the perfect solution. The booth, made from carbon fiber, has a high-tech look and can withstand the hassle of repeatedly setting up, dismantling and moving from city to city.

This product may expose you to chemicals such as Lead, Carbon Black, Silica, Crystalline which are known to the State of California to cause cancer and birth ...

Dec 4, 2023 — CVE-2023-24048 Detail. Modified. This vulnerability has been modified since it was last analyzed by the NVD. It is awaiting reanalysis which may ...

If you don’t understand the importance of feeds and speeds for CNC routing and milling, refer back to the explanation given in our Cutting Tool Guide. This page is meant to briefly explain some of the required terminology that you’ll need to know moving forward, and just as importantly, it will provide you with a table of recommended feeds and speeds that you can refer back to when you’d like to start cutting different types of materials.

Carbon fibermechanical properties Table

Spindle speed: the speed that the tool spins in the rotary tool, defined in RPM (rotations per minute). Most compact routers operate at speeds between 10,000 and 30,000 RPM.

Carbon fiber board is light in weight and good in flexibility: carbon fiber board has higher strength than steel, and its quality is only 1/5 of steel. It has high toughness, can be coiled, and can be supplied in larger lengths without overlapping.

Carbon fiber characteristicsand applications

In the field, military equipment often has to be moved over long distances with minimal resources, and reducing equipment weight means reducing energy to move equipment. This equates to saving time, effort and cost. Carbon fiber sheets are used in many military applications, from radar structures to tactical gear to drones for surveillance missions.

Carbon fiber board is a form of carbon fiber composite product. It is formed by impregnating carbon fiber with resin and then curing it in a mold. Compared with titanium, aluminum or steel, carbon fiber board is usually a better material choice.

Anyone who's worked on a corporate trade show knows that a company booth needs to be lightweight, durable, and look better than everyone else. Once again, carbon fiber panels provided the perfect solution. The booth, made from carbon fiber, has a high- tech look and can withstand the hassle of repeatedly setting up, dismantling and moving from city to city.

Oct 9, 2024 — Our buyers guide has the best ceramic coatings for cars to keep your car looking clean in a budget-friendly way.

Quasi-Isotropic Carbon Fiber Sheet: Designed for loading in multiple directions, this 0°/90°/45° fabric is ideal for torsional or off-axis loading due to the extra stiffness in the 45° direction.

Carbon fibermechanical properties

202115 — In this blog, we'll break down what makes wet carbon fiber wet, what makes dry carbon fiber dry, how they match up, and how to maintain them.

Tool Less Rack Mounting Bracket for P/Ns 356XX-XXX that are less or equal to 2 inches W (51 mm), Shipping Weight 2 lbs(0.9 kg)

Unless you’re doing 3D contour cutting where the z-axis moves up and down a lot, we usually recommended lower plunge rates (100mm/min to 300mm/min) for most materials.

0086-813-8127573

0086-813-8127573