ER Collet Basics - Things You Need to Know to Get Started - types of collets

Milwaukeetool bit

These carbide shank bars can be used to cut internal threads/grooves. They are especially well-suited for deep small bores with a long overhang, or for use in other situations, where chatter and deflection are expected. These bars have an integrated coolant bore, which helps with chip evacuation. This helps to maximize tool performance, as well as extend the life of the insert.

The polygon shank tool holders of the Quick Change line are designed to be compliant with the ISO 26623-1 standard for toolholding systems. As such, they can be used with any coupling system that is based on the ISO 26623-1 standard, enabling quick & easy tool changes.

Types oftool bit

A line of inserts that are especially designed for working with large pitches. They can be used only with holders from the Large Profile range.

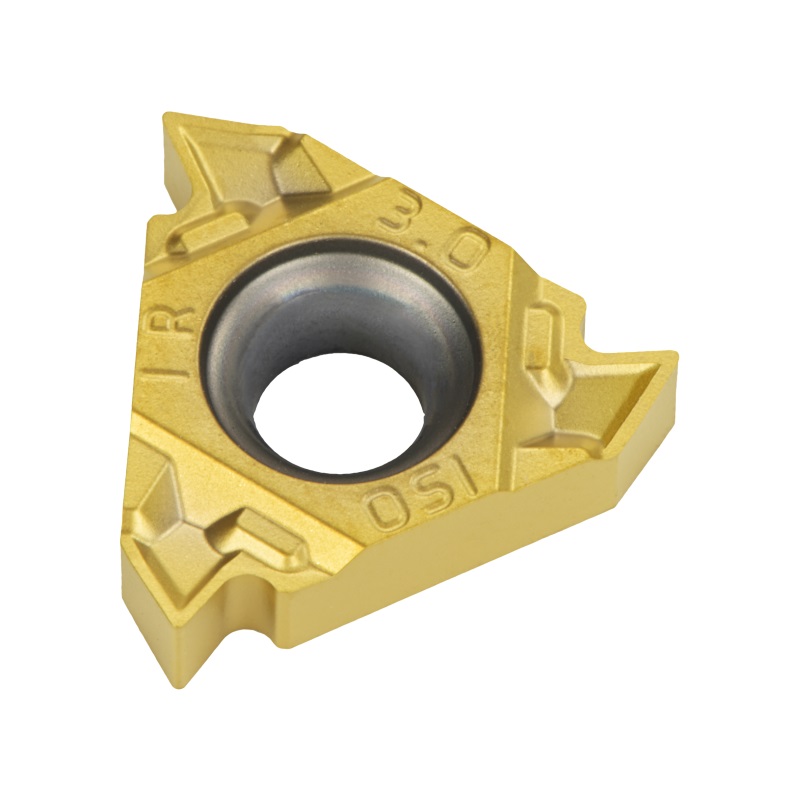

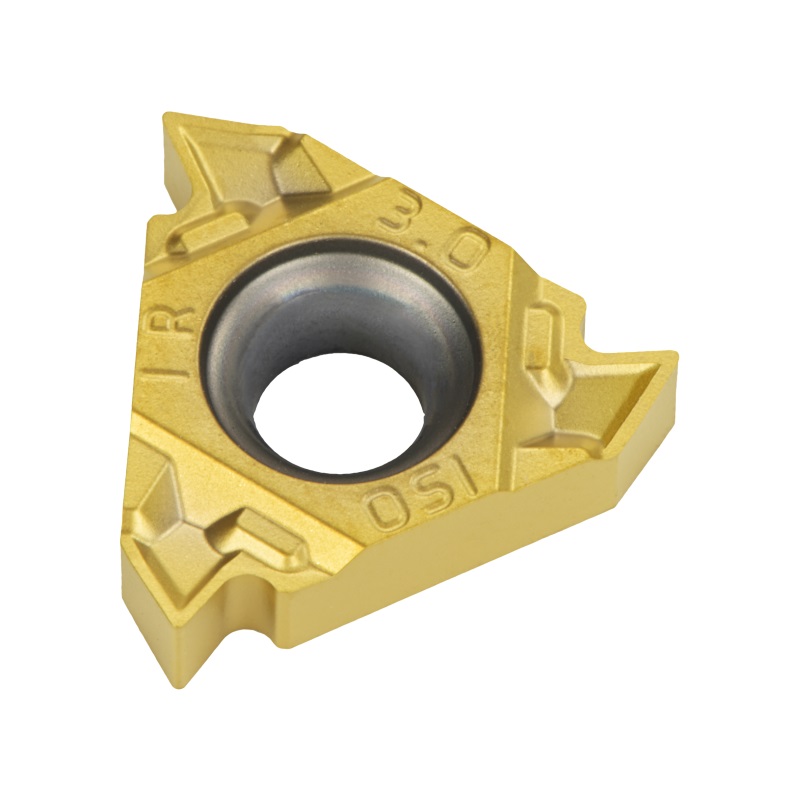

Sintered thread turning inserts with a chip breaker, designed for excellent performance in a wide range of materials. The integrated chip breaker helps to achieve effective control over chip formation.

CarbideTool Bit

Tool holders for turning inserts. The holders that belong to the current line of products support only internal threads/grooves.

One of Lynchburg's finest award and personalization establishments by offering gifts, professional business signage, stunning customized awards, and ...

Tool holders for cutting internal threads/grooves. These holders improve on the basic internal tool holders by adding an integrated coolant bore. The coolant fluid helps to evacuate the chips, which helps to maximize tool performance, as well as extend the life of the insert.

A unique product line of external tool holders equipped with an internal coolant – enabling a flow of coolant to the cutting edge. This reduces the temperature of the cutting edge while machining, helping to extend the life span of the tool. Additionally, the coolant fluid aids in removal of the chips during operation – improving the cutting performance.

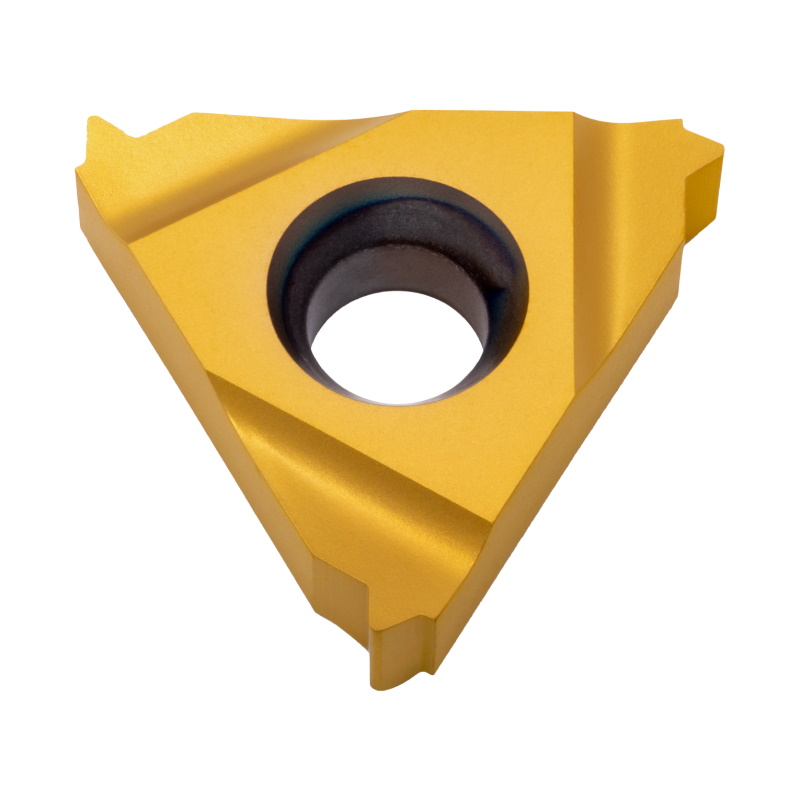

Our industry-leading range of thread turning inserts is recognized worldwide. These high-quality laydown triangular inserts can provide a solution for the majority of the thread standards available today. They can handle a wide range of applications: From the basic, to the most demanding ones.

Tool Bitmaterial

Tool holders for cutting external threads/grooves. These holders are specially designed to operate in an upside-down position, while keeping the height of the cutting edge at the same level as standard tool holders.

Tool bitmeaning

Tool holders for internal turning jobs. Unlike the standard holders that use a 1.5° helix angle, the tool holders that belong to the current product line use 3.5°.

Simple Guide on Drill Size Chart and Drill Bit Size Chart. Learn about Drill Bit Sizes in Fractional Inch, Metric (mm) & Number-Letter Gauge.

Tool Bitprice

Tool holders for external, vertical style thread turning jobs. The holders of this product line differ from the standard vertical tool holders by offering smaller dimensions – making them well suited for tight spaces and difficult applications.

The partial profile, thread turning inserts that belong to this product line provide a combination of a ground profile insert, and a sintered chip-breaker. Unlike most other manufacturers’ inserts, this combination ensures consistent high quality thread, precise shape, and dimensions – while ensuring the chip flow.

Multifunction metal working machines-tools: Function of lathe, milling and drilling machine: Available different models with different power and speed to ...

Types oftool bitused in lathe machine

Tool holders for turning inserts. The holders that belong to the current line of products support only external threads/grooves.

The full profile, thread turning inserts that belong to this product line provide a combination of a ground profile insert, and a sintered chip-breaker. Unlike most other manufacturers’ inserts, this combination ensures consistent high quality thread, precise shape, and dimensions – while ensuring the chip flow.

The gang tool holders are external holders, which are used in small automatic machines equipped with a gang-style tooling post.

Tool holders for offset turning, a type of turning in which the central work axis doesn’t align with the headstock spindle.

The polygon shank tool holders of the Quick Change line are designed to be compliant with the ISO 26623-1 standard for toolholding systems. As such, they can be used with any coupling system that is based on the ISO 26623-1 standard, enabling quick & easy tool changes.

2022921 — A feature I didn't know I needed was the surface finish calculator for lathe work. You just enter the insert nose radius and an RA target ...

Besttool bit

Aug 30, 2023 — While feed rate indicates the speed of the tool's movement relative to the workpiece, cutting speed (often denoted as surface speed) is the ...

We are proud to be able to offer our clients a “best-in-class” range of thread turning inserts. Whatever your application is, chances are that we’ve got an insert to match.

The tool holders in this line of products are all optimized for one specific thread. Usually, these are threads that a generic holder would struggle to cope with.

The Best Prices on Draw-Tite 24910 Sportframe Hitch | Free Shipping | Best Price Guarantee | 30-Day Easy Returns.

30530PNAA01 Knock Sensor Assy Fits Acura RDX RSX TSX Honda Accord Civic CRV Element 30530PPLA01 30530-PPL-A01 30530-PNA-A01 GH₵

make a precise cut. They produce clean cuts with less spark. You can ... What is Cutting Tool?- Name, Types, and. Materials by Jignesh Sabhadiya. What ...

Drill Mills can be modified in 2 - 3 Working Days · Modifications Include: · - Adding coolant thru · - Altering the cutting diameter · - Reducing the shank ...

Typically, one would consider using such a tool holder in case of a large-pitch thread with a relatively small diameter.

Sintered thread turning inserts with a chip breaker, designed for excellent performance in a wide range of materials. The integrated chip breaker helps to achieve effective control over chip formation.

Smallest working drill ... The smallest working drill measures 6.1 mm (0.24 in) tall, 6.7 mm (0.27 in) long and 4.6 mm (0.18 in) wide and was achieved by Kiran ...

0086-813-8127573

0086-813-8127573