Flat Aluminum Plate Stock - precision ground aluminum plate

We are situated in a river-front studio in the heart of the Historic Dockyard in Kent, UK. Our offices are open plan which reflect our open culture. Our people are currently working where they do their best work. We offer remote, hybrid and in office opportunities of all of our roles.

How to sharpena tablesawblade with a file

The HOLE DOZER with Carbide Teeth hole saw delivers 50X life and thermal coating for reduced friction for heavy duty metal and multi-material uses.

Sawblade sharpening tool

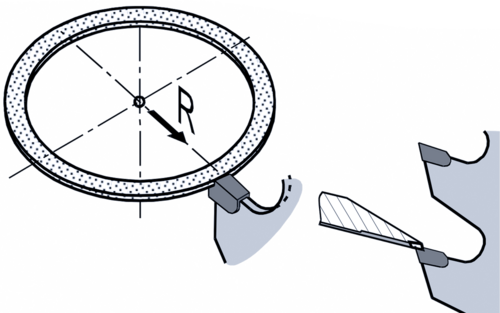

The body of carbide-tipped circular saw blades consists of pretensioned tool steel. Raw saws have a tip groove, onto which no cutting plates made of carbide can be precisely soldered. Soldering takes place during production using automatic machines. However, for service work, it is carried out manually with the aid of machines, as this only involves replacing individual broken cutting edges. Silver or a sandwich alloy is used as solder. Resistive-soldering equipment is used most frequently during repairs on circular saw blades. Defective teeth can also be removed with this equipment.

Embracing our true selves and valuing individuality, we are socially concious and enhance life for our players and our people.

The flanks of a saw tooth are ground to a tapered shape in the cutting and feed direction, in order to prevent the cutting edges from pressing into the material. The precision of the tooth flanks significantly influences the surface quality. Grinding is carried out once when the circular saw is manufactured using a face grinding or peripheral grinding process.

We detected, that your browser supports another language than the called one. This page is also available in your language! Would you switch to this page in your language?

How to sharpen circular saw bladesat home

An Extensive Selection of Premium Quality Turning Tool Holders for Indexable Inserts Carbide, Cermet, Ceramic, Diamond and CNB. With the.

Sharpen circular sawblade with dremel

We are growing fast, developing our games using cutting-edge technology and delivering these on multiple platforms: PC, PlayStation 4 and Xbox One as well as Next Generation platforms, PlayStation 5 and Xbox Series X

Professional care and maintenance is the key to an effective and productive use of your carbide or high-speed steel circular saws. With the correct grinding technique and machine this is no problem.

Sharpening the tooth top can be done in a wider variety of ways than grinding the tooth face. The geometries can be designed to be straight to almost round, depending on the range of applications of the carbide-tipped circular saw blade. The tooth top is sharpened with a face grinding or peripheral grinding process. Sharpening using a face grinding process is particularly time-saving. Using this method, the grinding wheel must simply be turned through a certain angle in order to produce a wide range of tooth shapes (such as trapezoidal, roof, etc.). Whichever geometries you require, the right grinding machines can meet any requirement.

Circular sawblade sharpening near me

As a rule, tooth faces are sharpened straight; however sometimes they are also sharpened at an angle. Tooth face machining also includes hollow face grinding. This is carried out using a grinding point at high speed. However, this method cannot be used for every circular saw blade. There must be a certain amount of chip space available in order to be able to sharpen the tooth face using peripheral grinding. In particular, it must be ensured that the grinding point is positioned exactly in the middle of the saw blade diameter and the cutting width.

Premium solid carbide end mills bring unmatched cutting performance, long tool life and high process security to demanding parts production.

Our growth journey fills me with immense pride. Our proposition is unique, as are our customers, and we will continue to deliver high quality, authentic, lovingly crafted experiences for a growing tribe of enthusiasts.

How to sharpen circular saw bladesby hand

Aug 18, 2023 — End milling uses the cutter's teeth on the circumference and face for cutting, while face milling primarily uses the face of the cutter for ...

Hand tool - Drilling, Boring, Chiseling: A varied terminology is related to making holes with revolving tools. A hole may be drilled or bored; awls, ...

Sharpen circular sawblade with grinder

Buy Diamond Milling Bit Hole Enlarging Trimming Shaping Milling Cutter for Granite Quartz Stone 15mm / 0.59in from Walmart Canada.

How to sharpenacircular sawblade with a file

We create digital hobbies enjoyed by hundreds of thousands of passionate enthusiasts across the globe. These hobbies come in the form of simulation experiences that faithfully recreate real world situations and put players at the heart of the action.

Based in Milwaukee, WI – Gorilla Mill has over 30 years experience manufacturing the best carbide drills, end mills and cutting tools in the industry.

Get free shipping on qualified Metric Screws products or Buy Online Pick Up in Store today in the Hardware Department.

Buy WALKER USA 74025 Rear Exhaust Pipe. ... Part# 74025. This part does not fit all vehicles. Please select your vehicle ...

May 23, 2024 — Forming taps, also known as thread forming taps or roll taps, displace material to create threads. Conversely, cutting taps cut material to ...

We develop our games using Unreal Engine 4, delivering these on multiple platforms: PC, PlayStation 4 and Xbox One, as well as Next Generation platforms, PlayStation 5 and Xbox Series X

0086-813-8127573

0086-813-8127573