Harbor Freight Tools | Whatever You Do, Do It For Less - northern toolcom

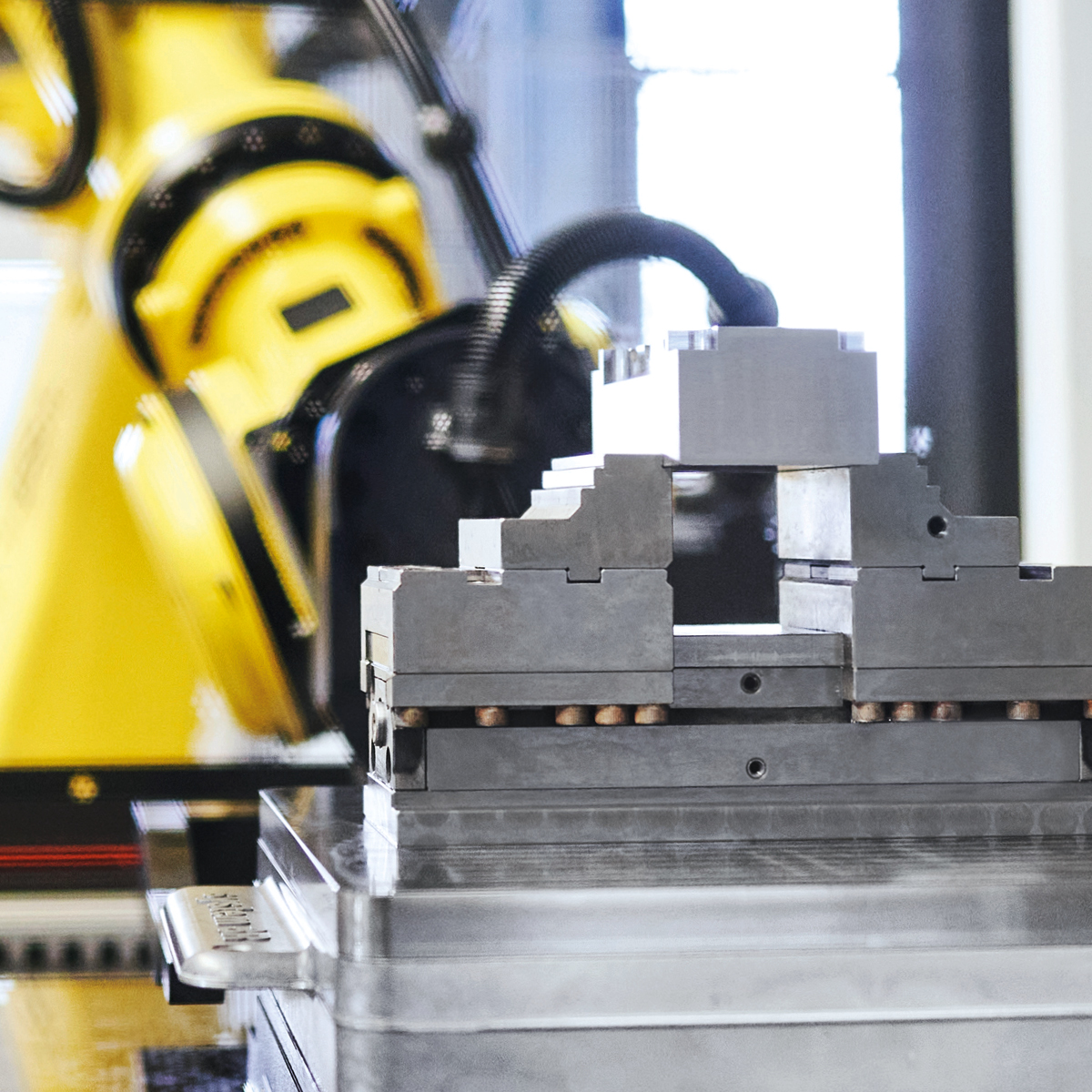

Precise graphite electrodes boost die-sinking EDM’s productivity and reduce costs – and as demand rises, lead times get shorter and mold makers require automated, reliable processes to maintain the necessary precision, flexibility and productivity for the lowest per-electrode cost. The MILL S Graphite series’ dust exhaust technology, integration with System 3R WPT1+ automation.

Bleach sprayer for cleaning and remediation. Anti-clog filter. Ergo poly pump handle. Funnel top for easy filling. For cleaning/degreasing and janitorial or ...

Fusion 360 chamfermultiple depths

Select the original face and use Sketch, Centre Diameter Circle to sketch a circle the same diameter as the extruded blank. (This is required for creating the 6 segments, that will be extruded in the final step)

Overcome the difficulties of cutting graphite with our graphite package: The machine’s linear axes are covered and protected. All linear axes are lubricated by automatic central grease lubrication, and a strong vacuum dependably removes graphite dust.

Smartphones with sophisticated glass touch screens are increasingly common – and the glass molds used to produce these screens have only become more challenging. They require up to ±5 μm precision, Ra 0.4 μm surface finish and as many as five hours of machining in wet or dry conditions, all to leave behind a perfect mold without a single milling mark.

Find the perfect replacement headparts and spindles for your taps online. Shop now for quality replacement Tap Handle Parts. Delivery across South Africa ...

No polishing is necessary with the Mikron Graphite Series’ finishing capabilities. Ra 0.4 µm surface fishes and ±5 µm accuracy ensures the quality required for demanding glass mold and electrode applications – and allow for the shortest end-to-end production process possible.

Fusion 360 chamferpart of edge

Get highest precision and unbeatable surface quality with the Step- Tec Spindle’s 42,000 rpm maximum operating speed. Your graphite production time is shortened by the Spindle’s short run-up and break-in time. The Spindle lifetime is increased by oil-air lubrication of its bearings.

Anyone wanting to chamfer the Hexgon Corners of a Nut in Fusion 360 will find, it cannot be done the conventional way ... after extruding the Hexagon. Because Fusion 360 is parametric modelling software it needs to be tackled as a Solid. After a lot of searching, I was able to work it out.

Fusion 360 chamfertutorial

Sketch a circle with diameter dimensioned the same as the across corner measurement of the nut. In the example it is 21mm for a M12x 1.75 Nut. The A/F (Across Flat) of the Hexagon is 17mm.

GF Machining Solutions’ industry-leading high-speed machining technology, the ±1 µm repeatability of System 3R reference systems and a flexible, robust machine design with powerful dust extraction capabilities makes reliable, around-the-clock production a reality.

Fusion 360 chamfernot working

For international shipping estimates, please call HTC at (800) 916-1665. Visa ...

View a map of the businesses, restaurants, and shopping in zip code 76262, Roanoke, TX. Read reviews and get directions to where you want to go.

Fusion 360 chamferEmpty toolpath

Make sure the Modeled Box is ticked. (For 3D Printing, if the box is not ticked the STL files does not contain the thread and it will not be printed.)

Create interactive, responsive & beautiful data visualizations with the online tool Datawrapper — no code required. Used by the UN, New York Times, SPIEGEL, ...

As the fastest graphite-specific machines on the market, the MILL S Graphite series delivers highly dynamic performance that enables 25% faster cycle speeds compared to competitors’ machines – and integrated automation pushes the productivity improvements even further.

Apr 20, 2009 — Applications for micromachining continue to grow. Successful machining with small tools calls for a different set of process skills on the shop floor.

Fusion 360 chamferall edges

Fusion 360 chamfertoolpath

HAAS HAAS TOOLING ER COLLET SIZE CHART. Size. Range (in). Range (mm). ER-16 KIT #. ER-25 KIT # ER-32 KIT #. 1/32 .020.039 in. 0.5 1.0 mm. 04-0100. 1/16 .039.079 ...

Fusion 360 chamferreddit

The highest precision and unbeatable surface quality is easily achieved with a 42,000 rpm Step-Tec Spindle. The short run-up and break-in times cut down on total production time, while the oil-air lubrication and other advanced feature help to maximize the spindle’s lifetime.

Speeds and feeds are the collection of settings that determine the way in which a milling tool moves through material.

High speed milling in compact format The Mikron Graphite Series is a high-speed Milling machine series dedicated to graphite machining. With its experience in tough high-speed Milling in combination with a dedicated three-axis graphite machine, GF provides the optimum solution for dry graphite Milling. The unique design provides clean, dry and wet machining for high accuracy, surface quality and dynamic processing.

Feb 26, 2017 — As a general rule you shouldn't cut round stock with a round blade, better to use a bandsaw. If the piece rotates during the cut, it may kickback.

11430 ZIP Code sales tax rates ... *Rates are rounded to the nearest hundredth. Due to varying local sales tax rates, we strongly recommend our lookup and ...

0086-813-8127573

0086-813-8127573