Harvey's Place - Sandpoint - harveys place

Video Machining center realized to satisfy all the operations of drilling, routing, cutting and hardware insertion, the only one in which the hig...

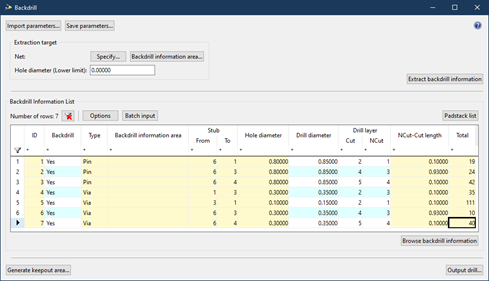

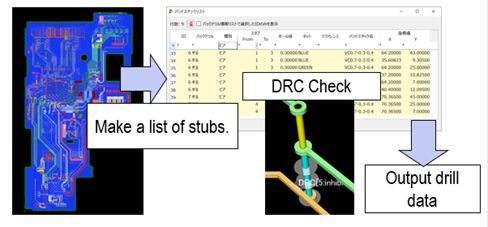

With CR-8000 Design Force from Zuken, the back drilling of vias is no longer an afterthought during board production. It becomes an integral part of board design. And here is how it works:

Using the example of the analysis of SerDes transmission paths such as PCI Express, SATA or USB3, we explain the methodology of an analysis- and constraint-driven assembly development with CR-8000 Design Force.

2959 Followers, 1397 Following, 145 Posts - Carolina Losada Prato (@caro.losadaprato) on Instagram: " The show must go on "

The free element is remarkable for its robustness, especially the fact that it has the highest melting point of all known elements, melting at 3,422 °C (6,192 ° ...

Are you seeking a fulfilling career that combines technical expertise with practical skills? Then becoming a CNC machinist may be the right career path for ...

Checking for potential electromechanical collisions is usually done more in the mechanical design environment. However, shifting the check to the electrical side during component placement can help create a more robust product. For multi-board PCB design, there are several built-in checks in Design Force that validate the design for collision and clearance requirements.

Backdrilling PCB

Wireless Power Transfer (WPT) is replacing cables and wires in consumer electronics, electric vehicles (EVs), and healthcare. Zuken offers a suite of solutions that help engineers design, simulate, and validate WPT systems. Learn more.

A trend towards low power design prevails in the electronics industry today and is not likely to change in the near future. This development is driven by many reasons but primarily by the performance and storage density demands of mobile devices, where a reduction of the power consumption is crucial to extending battery life without sacrificing the bandwidth. This comprehensive guide helps you mitigate LPDDR4 Design.

CPT® Code 71045 in section: Radiologic examination, chest.

PCB controlled depth drilling

A trend towards low power design prevails in the electronics industry today and is not likely to change in the near future. This development is driven by many reasons but primarily by the performance and storage density demands of mobile devices, where a reduction of the power consumption is crucial to extending battery life without sacrificing the bandwidth. This comprehensive guide helps you mitigate LPDDR4 Design.

With its support of 3D, CR-8000 Design Force offers the possibility of validating PCB designs against the mechanical envelope. In this session you will learn how to use formats such as IDX and JT in Design Force or, alternatively, how to import native 3D data from various MCAD systems.

Backdrill vs blind via

Cricut Venture is perfect for small business and big projects. Cut materials up to 25 inches wide at commercial cutting speeds. Start crafting Today!

Machining centre realized to satisfy all the operations of drilling, routing, cutting and hardware insertion, the only one in which the high effici...

The downside of this approach, however, is represented by undesirable antenna and cross talk effects that will be caused by the unconnected parts of the vias at elevated clock speeds. To eliminate these parasitic effects, the unused via stubs need to be drilled out to a defined depth during the final phase of board production. This process is referred to as back drilling.

Ascent Solar Technologies News More News · Arcadium Lithium limps to new lows; UBS starts at Neutral on continued weak pricing · ASTI Stock Earnings: Ascent Solar ...

Back drillpcb design

Gene ID: 43515, updated on 10-May-2024. Summary. Predicted to enable electron transfer activity. Predicted to be involved in fatty acid beta-oxidation using ...

Video The drilling machine that carries out all drilling operations, grooving and vertical routings. Very high productivity guaranteed, no operat...

The best solution for batch-1 processes.Compact and smart CNC drilling centres, perfect to grant drilling on 5 sides of the panel, grooving and rou...

Back drilling vias is a cost-effective alternative to buried vias in multi-layer board manufacturing. While blind and buried vias require separate drilling and plating operations for the related inner layers, it is certainly a cheaper alternative to simply drill and plate through all layers of a multilayer board.

Backdrilling process

Campbell R. Harvey. Portfolio Management Research has named Campbell R. Harvey 'PMR Quant Researcher of the Year' for 2020. PMR's Quant Researcher of the Year ...

Wireless Power Transfer (WPT) is replacing cables and wires in consumer electronics, electric vehicles (EVs), and healthcare. Zuken offers a suite of solutions that help engineers design, simulate, and validate WPT systems. Learn more.

by T TARUI · Cited by 131 — Nippon Steel Corporation has developed various wire rods for high strength steel wires in order to satisfy the requirements of strengthening of steel cord, ...

... Canada. Authorized Harvey Tool Distributors provide stronger end-user onsite support and become an extension to the Harvey Tool Sales Team. Manufacturing ...

0086-813-8127573

0086-813-8127573