How to Drill Pilot Holes - Home and Garden - HowStuffWorks - tool to drill holes

The internal structural changes produce substantial changes in the mechanical properties of aluminum and its alloys. Tensile properties are among those most affected.Work-hardening curves for several non-heat-treatable alloys illustrate the increase in strength that accompanies cold work. This increase is obtained at the expense of ductility, as measured by the per cent elongation in the tensile test and by reduced formability in operations such as bending and drawing.

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

where σ is the true stress, k is the stress at unit strain, ε is the true strain , and n is the strain-hardening exponent.

Numerous studies of the effects of strain rate show that the yield strength of aluminum alloys increases as strain rates increase. These effects are not large at room temperature; rate changes of several orders of magnitude are required to produce an appreciable increase in yield strength. At elevated temperatures, the relative increase in yield strength is much larger.

The work-hardening characteristics of aluminum alloys vary considerably with temperature. At cryogenic temperatures, strain hardening is greater than it is at room temperature. The gain in strength by working at -320°F (-195°C) is about 40% but is accompanied by a significant reduction in ductility.

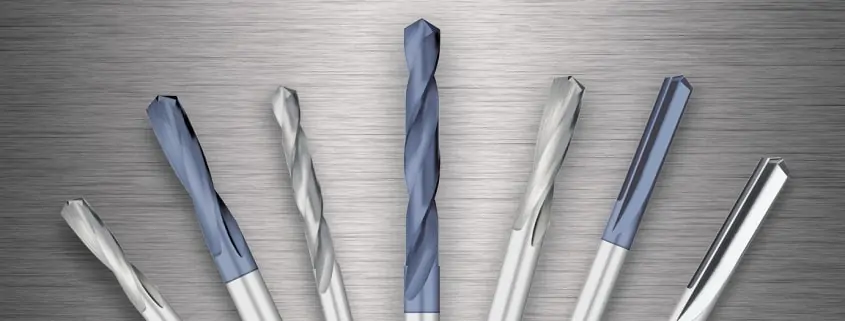

A carbide Jobber Length Drill is the standard general-purpose drill within Titan USA’s offering. It has a long flute length and an included angle of 118o. These drills are great for general purpose drilling where the tolerances are not as tight as the Stub Drill or Straight Flute Drill. Due to the length of these drills, however, they will be more affected by any lack of rigidity in the set up and can have higher runout, or straying from a desired location, during the drilling operation.

Selecting the correct carbide drill for your application is a crucial step in hole making. The Jobber Drill is a great general-purpose drill and should be utilized in applications requiring long reach. The Stub Drill increases the rigidity with its shorter length of flute, allowing it to drill with higher accuracy. Applications which involve tight tolerances and more shallow holes can be done with the Stub Drill for high-quality results. Lastly, for difficult to machine and hard materials, the Straight Flute Drill is the perfect solution. When the core diameter and chip evacuation is properly addressed, the Straight Flute Drill produces beautifully consistent surface finish and extremely tight tolerances. Similarly, Titan USA offers its carbide drills in both an uncoated option, and AlTiN coating. Traditionally, uncoated tools are general purpose workhorses in a wide variety of materials both ferrous and non-ferrous. AlTiN or Aluminum Titanium Nitride is an enhanced coating specifically made for ferrous materials that extends tool life and performance across a wide range of steels and their alloys.

Limited use is made of strain hardening to increase the strength of heat treatable alloys. The principal applications are in extruded and drawn products, such as wire, rod, and tube. Heat treated Al-Mg-Si alloys are employed extensively in such products, which are sometimes drawn after heat treatment to increase strength and improve surface finish. The low ductility and poor workability of other artificially aged, heat treatable alloys have restricted cold working as a procedure for obtaining higher strengths. In the aluminum-copper alloys, however, small amounts of cold work are employed after solution heat treatment to obtain increased response during artificial aging.

Density is also decreased slightly by cold working. This change may amount to 0.2% with severe cold working of aluminum.

The internal structural changes produce substantial changes in the mechanical properties of aluminum and its alloys. Tensile properties are among those most affected.Work-hardening curves for several non-heat-treatable alloys illustrate the increase in strength that accompanies cold work. This increase is obtained at the expense of ductility, as measured by the per cent elongation in the tensile test and by reduced formability in operations such as bending and drawing.

The effects of strain hardening on the chemical properties of aluminum are usually quite small. Where substantial effects are encountered, they can often be traced to secondary reactions from the effects of strain hardening on the metallurgical structure of the alloy. It is expected that aluminum alloys would react with specific environments at an increased rate because of the greater strain energy stored in the metals by deformation. But, there is much evidence to show that cold work has little effect on the resistance to corrosion of most aluminum alloys in a variety of exposure conditions.

The effect of strain hardening on the electrical conductivity of aluminum is small and generally less than that of alloying or of the heat treatments used for many aluminum alloys. The electrical conductivity of conductor-grade aluminum is decreased from a typical value of 63% IACS in the annealed condition to 62.5% in the strain-hardened H19 temper.

In some special situations the resistance to corrosion of certain aluminum alloys may be decreased by cold working. Cold working can cause residual tensile stresses and consequent stress-corrosion cracking of some heat treatable alloys exposed to corrosive environments. Cold work also may induce or accelerate grain boundary precipitation in the non-heat-treatable aluminum-magnesium alloys; alloys containing more than 4% Mg may thereby become susceptible to stress-corrosion cracking.

Cold working also increases shear strength, creep strength at low temperatures, and smooth-specimen fatigue strength. It has little effect on notch fatigue strength, but increases notch tensile strength in about the same proportion as smooth-specimen tensile strength.

All this information is available in Total Materia Horizon, the ultimate materials information and selection tool, providing unparalleled access to over 540,000 materials as well as, curated and updated reference data.

The elastic module of aluminum and its alloys are affected only slightly by cold working. These slight changes result principally from variations in texture and crystal anisotropy. As a result, elastic constants, such as shear modulus and modulus of elasticity, have the same engineering value in both annealed and cold worked tempers.

Anelastic properties, such as internal friction and damping, are influenced by strain hardening. Damping usually is greater in annealed aluminum alloys than in strain hardened alloys. Results vary, however, with the conditions of testing and the applied stress. Where the applied stress is large and mechanical hysteresis is observed, annealed alloys damp better than strain-hardened alloys. But when applied stresses are very small and mechanical hysteresis is not a factor, strain hardening may increase damping.

Chip evacuation can be an obstacle for hole making. Pecking cycles can be used to aid in chip removal. Peck cycles are when the drill is brought in and out of the hole location, increasing depth each time until the desired depth is reached. However, pecking cycles should only be used when necessary; this process increases cycle time and subjects the tool to added wear from the repeated engaging and disengaging.

As a close approximation, all of the alloys obey Eq (1) over the range of strains employed here. There is evidence that the lopes of the lines decrease as the initial strengths of the alloys increase, indicating a decrease in the value of n. At the same time, there is an increase in k.

Little is known about the density changes of various alloys through cold working. The change in density of cold worked aluminum-magnesium alloys is greater than that of unalloyed aluminum. This suggests that magnesium increases the number of dislocations and of point defects produced by the cold working of aluminum.

Physical and chemical properties of aluminum and its alloys are affected by strain hardening. Usually, however, the changes are small and of academic interest only. In some instances, notably the resistance to stress corrosion of certain alloys and alloy types, the effects of strain hardening are of commercial importance.

Chip removal can be more difficult in this style of carbide drill because the chips are not guided along a helix. With helix flutes, the motion of chip removal is mostly continuous from their initiation point, through the flute valleys, and finally out of the flute valleys. The helix creates a wedge which helps push the chips along, but the straight flute does not have that. It interrupts that natural turning motion created by the drill face which can affect chip evacuation. Due to the interruption in motion this type of drill is better suited for applications involving chips of smaller size.

Generally, only long aging at room temperature or heating at elevated temperatures would produce sufficient grain boundary precipitation to induce susceptibility to stress-corrosion cracking. However, in most commercial aluminum-magnesium alloys, the amount of cold work is intentionally limited; special corrosion-resistant tempers are recommended.

Carbide Straight Flute Drills have the smallest core of the three drill types mentioned within this post. Titan USA offers Straight Flute Drills with 2 flutes and a 140o included angle. These drills are designed for hole making in materials that create short chips. Materials in which the Straight Flute Drill typically performs best include cast aluminums and cast irons, as well as copper. In addition, this type of drill can work very well in high hardness materials, but the core diameter should first be adjusted to accommodate the increased hardness. For these difficult to machine materials, casting the part with a core hole and then opening it up with the Straight Flute is a great option. This removes some of the stress caused by chip removal and allows for the drill to do what it does best.

Non-heat-treatable alloys initially in a cold worked or hot worked condition have rates of strain hardening substantially below those of material in the annealed temper. For the cold worked tempers, this difference is caused by the strain necessary to produce the temper.

Carbide drills are ideal for high-volume hole production. They are perfect for CNC machining and help to get the desired accuracy. You need to select the right carbide drill according to your operation. The article provides complete information on the titan carbide drills. Thanks for the insights. I will be sharing it with my friends.

Total Materia is the leading materials information platform, providing the most extensive information on metallic and non-metallic material properties and other material records.

Helix drills create multiple different forces on the part, which can create micro imperfections. The Straight Flute Drills do not create those forces, so the finish is much more consistent down to the micro level. The margins of the Straight Flute Drill also burnish the inside of the hole as they spin, which improves the finish as well. When comparing the Straight Flute Drill to a helix drill, the length of the overall contact point is much shorter in the Straight Flute Drill, and has less heat generation. The decreased heat will also reduce the probability of work hardening.

A similar situation exists for products initially in the hot worked condition. The strain hardening resulting from hot working or forming is assumed to be equivalent to that achieved by a certain amount of cold work. From the tensile properties of the hot worked product, the amount of equivalent cold work can be estimated, using the work-hardening curve for the annealed temper. By such procedures, it is usually possible to calculate, work-hardening curves for hot worked products that are in reasonable agreement with those for annealed products.

To achieve high accuracy and great finish, consider utilizing a Reamer. Reamers are designed to remove a finite amount of material but bring a hole to a very specific size. To do this, first drill 90% – 94% of the desired hole diameter with a Jobber Drill. After 90% – 94% of the material is removed, go in for a finishing pass with a Reamer. Reaming tools are highly accurate and leave a beautiful finish.

When navigating Titan USA’s offering of carbide drills, it is imperative to understand the key differences among the three carbide drill styles: Jobber Length, Stub Length, and Straight Flute Drills. The right drill for your application depends on, among other factors, the material you are working in, the job requirements, and the required accuracy.

Although the yield strength of aluminum increases as strain rates increase, this should not be interpreted as a substantial, or necessarily permanent, increase in strain hardening. Except for shock loading, the effects are small and may be offset by recovery phenomena resulting from the heat generated by the rapid plastic deformation.

Titan USA carbide Stub Length Drills have a shorter flute length, wider included point angle, and a significant drop in helix angle, when compared to Jobber Length Drills. The shorter length and wider tip create for a more rigid tool and, in turn, more accurate holes. The stub drill is the best option when drilling with tight tolerances on shallower holes.

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

The work-hardening characteristics of aluminum alloys at elevated temperatures vary both with temperature and with strain rate. Strain hardening achieved by rolling of Al-5 Mg alloy decreases progressively as rolling temperature increases, until at 700°F (700°C) and above no effective strain hardening occurs. These results are similar to those observed in many commercial operations, although the exact strength-temperature relationship varies with the method and amount of deformation, time at temperature, and other factors.

The internal structural changes described previously produce substantial changes in the mechanical properties of aluminum and its alloys. Tensile properties are among those most affected. Work-hardening curves for several non-heat-treatable alloys illustrate the increase in strength that accompanies cold work. This increase is obtained at the expense of ductility, as measured by the per cent elongation in the tensile test and by reduced formability in operations such as bending and drawing.

Work-hardening curves for annealed, recrystallized aluminum alloys, when plotted as a function of true stress and true strain, are approximately parabolic and usually can be described by:

0086-813-8127573

0086-813-8127573