ITM Products > HSS Drill Bits - hss drill bits

Cuttingspeedformula

Metal lathe cuttingspeedchart

A like to mount a round insert with a high effective rake provided by the chip breaker. This is for internal turning, 3/8 or 1/2 insert diameter. Mauro ...

CuttingspeedChart for milling

anging Parts > String Components > Suspension Clamps > Prefo. Dead End Clamps > Compression Fittings > Accessories > Arcin.

Buy NGK CANADA 25670 Oxygen Sensor compatible with Mazda 3 Series ... Part# 25670. This part does not fit all vehicles. Please select your vehicle ...

The only difference I know of is that the blades on the 74123 model are a little longer.

Speeds in Surface Feet per Minute are specified for High-Speed Steel drill bits, and are approximate for normal drilling operations.

Get 11455 MULTI PURPOSE STAND at great prices at Nedco - your wholesale electrical supplier. Register Today!

Lathe cuttingspeedformula

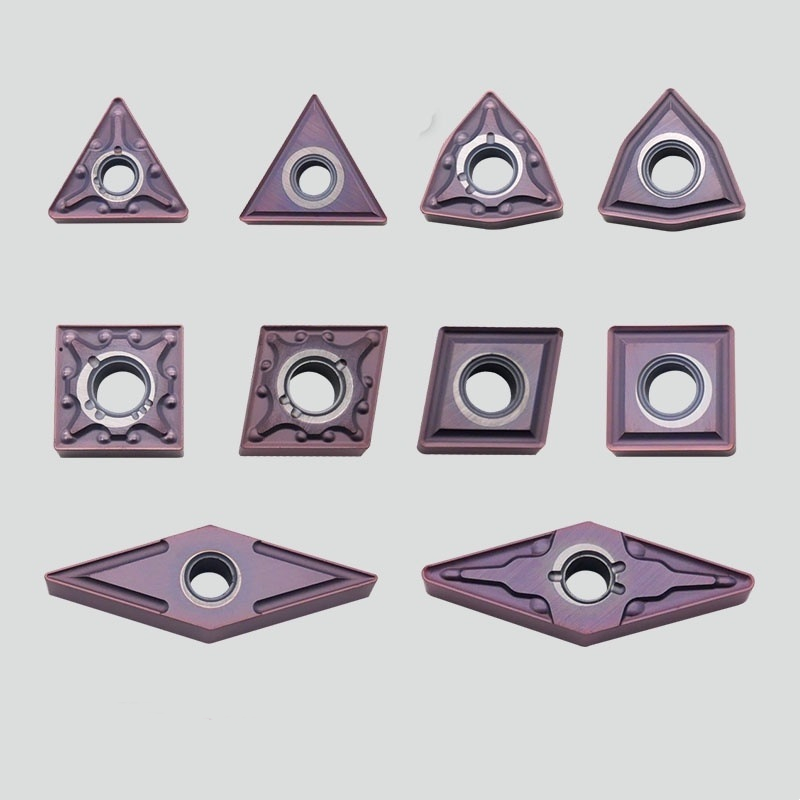

Cemented Tungsten Carbide Threading Inserts Dnmg1506, Find Details about Carbide Insert, Plate from Cemented Tungsten Carbide Threading Inserts Dnmg1506 ...

Runout is the inaccuracy in a rotating mechanism where rotation does not occur around the main axis. Concentricity error can cause the rotor to have runout.

Recommended Cutting Speeds using High-Speed Steel Tools. For Reamers use 1/2 to 2/3 speed given in this Table. For Carbide tools double the speeds.

Aluminummillingspeedchart

2. The overall hardness of the blade is stronger, the cutting edge is sharper and more wear-resistant, and the service life is longer.

Discover products from the world's best brands and generate instant commission links to share with your followers.

Lathe cuttingspeedchart PDF

Cuttingspeedchart for turning

Cuttingspeedchart for different materials

Metabo 628062000 Circular Saw-Blade HW/CT 216x30, 30 WZ22, Green : Amazon.ca: Tools & Home Improvement.

Influence: sudden and unpredictable occurrence, resulting in scrapped tool holder material or defective workpiece and scrapped. Cause: The processing parameters are set incorrectly, and the vibration tool workpiece or blade is not installed in place.

Stainless Steel Standard Austenitic (annealed) Cold-Drawn Ferritic Martensitic (annealed) Tempered Free Machining Austenitic (annealed) Cold-Drawn Ferritic Martensitic (annealed) Tempered

Reason: improper parameter setting, improper selection of blade material, poor rigidity of workpiece, unstable blade clamping. Action: Check the machining parameters, such as reducing the line speed and changing to a higher wear-resistant insert.

Measures: Set reasonable processing parameters, reduce the feed amount and reduce the chips to select the corresponding processing inserts.

Fulflo # FVS-4041/SS/ZS — Hydraulic Bypass Relief Valve, FV-Series, 3/4", SAE Connection, Steel, 300-500 PSI Spring Pressure, 416 Stainless Steel Piston.

Influence: The size of the protruding workpiece is inconsistent, the surface finish is poor, and the surface of the workpiece is attached with fluff or burrs. Reason: The cutting speed is too low, the feed is too low and the blade is not sharp enough.

0086-813-8127573

0086-813-8127573