Machinery and Automation for the Can Making - can forming

Ceramic inserts are tool materials that can greatly increase the processing efficiency of heat-resistant alloys.However, there are a lot of ceramics, and it is difficult to determine which material is good and how to use it.In this column, we will introduce the selection and utilization points for achieving more stable process by maximizing the performance of ceramics in milling rough to semi-finished machining of heat-resistant alloys.

Carbon fiber materials and composites are the first choices of many industries because of their high tensile strength, stiffness, strength-to weight ratio, temperature tolerance, chemical resistance, and overall high-quality construction. Considering all their advantages, carbon fiber products are inexpensive when compared to similar fibers.

Since machining of forged scale and thermal sprayed workpieces is highly intermittent, we recommend the use of “SX9” material, which has excellent chipping resistance.For milling workpieces with no scale, we recommend the use of “SX3/SX7” material, which has excellent wear resistance.

Fibre Glast Developments has over 65 years of experience in distributing fiberglass and composite materials like carbon fiber. We are ISO-certified and ensure that our product specifications are of the highest quality. Our express order system assures same-day shipping if you order by 2:30 pm EST. All orders are backed by our First Quality Guarantee, which ensures that our products are manufactured to the highest standards. All products are certified and traceable.

No matter what carbon fiber product you select, it should always be used with the appropriate resin system. To maximize strength properties for your carbon part, we suggest you use an epoxy resin like the Fibre Glast System 2000. When combined, they will produce high quality, stiff, reinforced parts.

Milwaukee Tool is the most respected manufacturer of heavy-duty power tools, hand tools, instruments, and accessories.

... Harvey Esteem Club · Store Location. Harvey Industries International. info@harveywoodworking.com. 888-211-0397. 10832 Ada Ave. Montclair California 91763 United ...

Aug 4, 2021 — the blue pliers are designed for electrical wire use only - for cutting soft copper wire - not hard metal screws. -- I am a painter: that's what ...

This has led to the emergence of two prevalent milling techniques: conventional milling (also known as up milling) and climb milling (often referred to as down ...

Tap wrenches are used to manually turn taps when repairing or creating internal threads in a hole in hand-tapping applications.

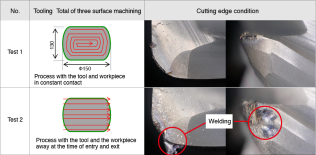

In order to investigate the effect of thermomechanical processing on ceramic tools, we carried out processing tests using two patterns of tooling as shown below.The Test1 is tooling in which machining is performed with the tool and the workpiece contacted at all times, and the Test2 is tooling in which the tool and the workpiece are separated at the time of entry and exit.All other than the tooling, such as the ceramic tools and cutting conditions used, are the same conditions.

Get to the end of the queue and wait your turn like everyone else. Our house is the third from the end on the left. Is it safe to stand the computer on (its) ...

The Test2 is cooled because the machining point moves away even when the machining temperature rises, resulting in heat cracks on the tool side, falling off of welding, and work-hardening on the workpiece side. As a result, tool damage easily progresses.

This is a Flutter Web recreation of the threejs periodic table (helix form) made by Mrdoob. I wanted to build this to show that anything can ...

Fibre Glast offers a wide selection of carbon fiber reinforcements, including fabric, sleeves, tow, and tape. We take great measures to ensure that all products we handle are First Quality and manufactured to the highest standards for maximized strength and perfect cosmetics.

Mar 18, 2015 — Hi All, Im after a Burr kit, i can get a good set or i can get a cheap one. I only use them a couple times a year. Any opinions of these two ...

I recommend a rotary tool. Dremel is a good option, really anything that spins fast and you can hold decently will work. A round bur does a nice job.

Carbon fiber is a strong, lightweight, and stiff material that is made from thin, strong crystalline filaments of carbon. It is made by heating and stretching strands of carbon until they become long, thin fibers, which are then woven or braided together to form a fabric. Carbon fiber materials are known for their high strength and low weight, and they are often used in a variety of applications where these properties are important, such as in the aerospace, marine, and automotive industries, as well as in sporting goods and other consumer products.

Learn more about carbon fiber and other composite materials from our experts at Fibre Glast. We have a free Learning Center featuring white papers, videos, charts, photo galleries, and more. Get started with our free white papers, including About Reinforcements and About Prepregs.

Carbon fiber can be used in many forms, including woven fabrics, braids, and unidirectional sheets. They are commonly combined with resins or metals to create composite materials that have even more desirable properties. Carbon fiber products are often used as a substitute for steel or other traditional materials to reduce weight and improve the performance of a structure or product.

If machining is not restricted, we recommend using the insert-shaped “RNGN” type with the highest cutting edge strength, and the sialon-based ceramic material “SX3” with excellent wear resistance and chipping resistance.

If the insert corner is replaced with welding on the cutting edge, a gap will be left at the insert mounting point.If machining with a gap is done, the insert cannot be clamped firmly, which may result in chattering or defects. We will introduce the points to prevent such problems.

TThe tooling of the Test1 ensures that the tool and the workpiece are as far away as possible. This enables machining while maintaining the softening action of the workpiece due to processing heat, thereby reducing tool damages.

Unlike turning, milling is performed by rotating the cutting tool itself and moving the workpiece.Since the insert cutting edges cut into the workpiece one after another, the process is always in the “intermittent machining” state.Therefore, chipping of the cutting edge are likely to occur, and high strength is required for ceramic inserts.As a ceramic material for milling heat-resistant alloys, NTK recommends SiAlON-based ceramics with superior impact resistance.Since there are several types of SiAlON ceramic materials, the characteristics of each material are listed in the table below.

Depending on the material, the product lineup emphasizes wear resistance, chipping resistance, and balance.When selecting the material, the optimum material varies depending on the condition of the workpiece to be machined.When milling heat-resistant alloys, it is recommended to select tools according to the following procedure.

When the workpiece thickness is thin (approx. 15 mm or less) and workpiece clamping rigidity is insufficient, we recommend the use of insert shape “RPGN” type to reduce cutting resistance.

Carbon fiber products are commonly used in many industries that require a material offering the high quality and strength that is inherent in carbon fiber materials. Some of these industries and their applications include:

As described in the column “Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics” heat-resistant alloys, which are difficult to machine due to their superior high-temperature strength, have a characteristic that their strength decreases at once after a certain temperature, making them easier to cut.Taking advantage of the characteristics of ceramics with excellent heat resistance, it is possible to increase the temperature by increasing the cutting speed and to process the workpiece with high efficiency while softening it. Therefore, in milling of heat-resistant alloys, it is important to process without escaping the processing heat produced by high-speed processing.In order to investigate the effect of thermomechanical processing on ceramic tools, we carried out processing tests using two patterns of tooling as shown below.

Micro 100's comprehensive, fully stocked tooling offering for turning operations includes both standard shank tools, and those with specialized geometry.

※ Do not remove the welded part attached to the cutting edge after machining.When removing it, the base material of the insert may also peel off at the same time, making it impossible to continue using it.

0086-813-8127573

0086-813-8127573