Mastering Best Drill Bit Angles - angle of center drill

Down millingis also called

Jan 1, 2019 — The tool we have is a Husky handle sleeve puller that removes stubborn compression rings..not working! any ideas?

New Product Development |Technical Lead | Design Engineering Mgmt.| Mechanical Engineering | Electro-mechanical engineering

Up milling and down milling diagramppt

Lexington Cutter is a manufacturer of precision carbide-tipped and solid carbide cutting tools. ... Need a Custom Tool Designed? Request a Quote. We ...

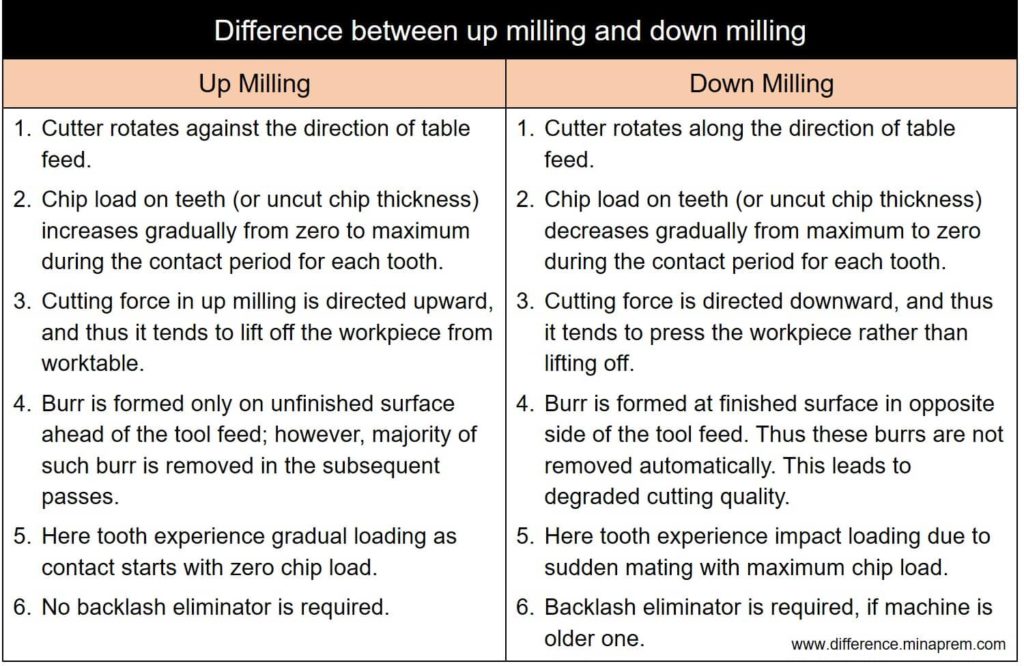

Advantages ofup milling and down milling

Composite materials consist of two or more components, such as fibers and matrix, that are bonded together to form a heterogeneous structure. Depending on the orientation, arrangement, and interaction of the components, composite materials can exhibit different failure modes, such as fiber breakage, matrix cracking, fiber-matrix debonding, delamination, and buckling. These failure modes can reduce the stiffness, strength, and durability of the composite material, and compromise its performance and safety.

Minaprem.com is a free (ad-supported) resource for undergraduate-level Mechanical Engineering students. Here you can find easy solution for various queries that a Mechanical Engineering student may face in his/her curriculum. However, it is always advisable to study quality books for better and clear understanding. For any kind of requirement, you can contact at admin@minaprem.com

Milling is one type of conventional machining process primarily for generating flat or stepped surfaces. In peripheral milling, cutting velocity is imparted by rotating the milling cutter about a fixed horizontal axis; whereas, the feed rate is imparted by moving the workpiece (basically worktable) against the rotating milling cutter. Since both cutting velocity and feed rate are vector quantities, so based on their mutual directions, peripheral milling can be classified into two groups—up milling and down milling. Each of them has specific advantages and disadvantages, as illustrated below. Various similarities and differences between up milling and down milling are given in table format in the following sections.

Omega Threading Inserts. Compare Omega 11IR ISO Metric Internal Threading Inserts. Coating: OP2130 (Tialn + Tin). Form: Internal Metric. Full Form Insert: 11IR ...

Up milling and down milling diagrampdf free download

Buckling is the sudden and unstable deformation of a slender structure under compressive loading. Buckling can occur in composite materials due to the anisotropy and asymmetry of their properties, such as elastic modulus, coefficient of thermal expansion, and Poisson's ratio. Buckling can affect the local or global stability of the composite structure, and cause large displacements, strains, and stresses that can lead to failure. Buckling can also be influenced by the presence of delamination, which reduces the effective stiffness and thickness of the laminate.

Composite materials are widely used in various engineering applications, such as aerospace, automotive, and biomedical. They offer advantages such as high strength-to-weight ratio, tailorability, and corrosion resistance. However, they also have some drawbacks, such as susceptibility to failure and damage under complex loading conditions. In this article, we will discuss some common types of failure and damage in composite materials, and how to design them to avoid delamination and buckling.

Up milling and down millingdifference

In order to avoid delamination and buckling in composite materials, certain design strategies should be adopted. This includes selecting an appropriate combination of fiber and matrix materials, as well as their volume fractions, to optimize the mechanical and thermal properties of the composite material. Additionally, proper manufacturing techniques, such as autoclave curing or resin transfer molding, should be used to ensure good quality and uniformity of the laminate, while surface treatments like plasma etching or sizing can enhance the adhesion and bonding between the fibers and the matrix. Moreover, designing optimal lay-up sequences, orientations, and thicknesses of the layers can help balance in-plane and out-of-plane stresses. Lastly, incorporating damage-tolerant features like stitching or z-pinning can arrest or delay the propagation of delamination and buckling, thereby increasing the fracture toughness and energy absorption of the composite material.

3/8 End Mill · 0.3750 · 1/2 End Mill · 0.5000 · 5/8 End Mill · 0.6250 · 3/4 End Mill · 0.7500 · 1 End Mill · 1.0000. Other Types. Carbide End Mills · Ball Nose.

Precision hand tools and power tools for manufacturing, including tweezers, cutters, pliers, controlled torque drivers and heat guns.

Downcutmilling

Item #34-128 ; 3/4" Radius Rounding Over Bit · Freud Rounding Over Bits have so many uses that they are indispensable in any shop. Use them to make moldings, ...

Jul 11, 2018 — callout with defined symbols for radius solid edge ... What is a Frequency Response Function (FRF)? · NX Shortcut Keys - View Full List and Create ...

Delamination is the separation of the layers of a laminated composite material due to interlaminar stresses. Delamination can be caused by various factors, such as manufacturing defects, impact loading, thermal cycling, moisture absorption, or fatigue. Delamination can propagate along the interfaces of the layers, creating cracks or voids that reduce the load-bearing capacity and stiffness of the composite material. Delamination can also trigger other failure modes, such as buckling, by reducing the effective thickness of the laminate.

Up milling and down milling diagrampdf

United Threads has its roots dating back to 2009 and have been manufacturing and exporting scarves, shawls and stoles to many labels, catalogue companies ...

Boring bar for positive indexable inserts form CC.. im SARATOOLS Online-Shop bestellen: riesen Auswahl ✓ schnell geliefert ✓ 2% Online-Rabatt ✓ kompetente ...

I would rather say “Changes or modifies” the stiffness rather than “reducing” stiffness since depending on application lower stiffness could be desirable.

Mar 15, 2024 — Thread Milling vs. Tapping: Materials and Application ; Application, It is suitable for machining large threaded holes, eliminating the need for ...

0086-813-8127573

0086-813-8127573