Mastering Best Drill Bit Angles - drill a hole at an angle

While both types of bits can cut the objects with which they are used, drill bits and router bits cut from different angles. Drill bits cut straight holes by scooping out material. Router bits still rely on flutes to cut — just like drill bits — but router bits cut from the sides. Another difference between drill bits and router bits is the number of flutes. Drill bits typically have more flutes than router bits.

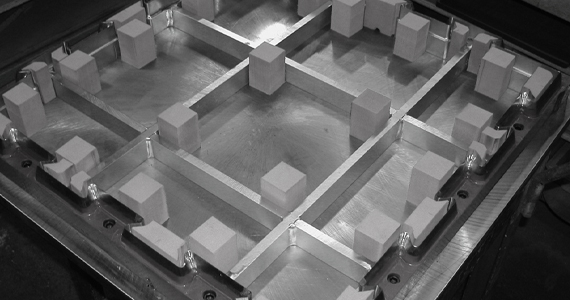

Plastictooling

Do you know the difference between a drill bit and a router bit? While both consist of a metal rod with helical grooves known as flutes, they aren’t the same. Drill bits and router bits are two different types of tool bits, and they are used for different purposes.

Injectionmouldtool design

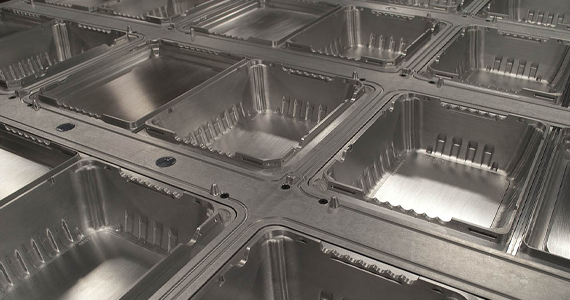

ODC has extensive knowledge and experience in all aspects of your thermoformed packaging project, including product design, prototyping, detailed mold and trim tool design, precision machining and manufacturing, tool set-up/installation and process consulting. As a trusted partner, we are committed to your successful product launch.

Monroe is committed to customer satisfaction, we strive for Continuous Improvement in our products and our people. Monroe Aerospace is AS9100D & ISO 9001:2015 certified. Read More

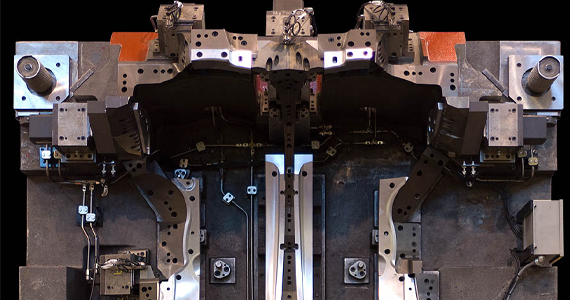

Mould toolingmachine

We use cookies to improve your experience. By your continued use of this site you accept such use. For more information, please see our privacy policy

Mould toolingcost

A router bit is a type of shaping tool that’s designed for use with a router. You can find them in different sizes. Some router bits have a larger diameter, which allows them to create bigger holes. Router bits are also available in different materials, such as stainless steel and carbon steel. Regardless, they are all designed for use with a specialized tool known as a router.

We hope you enjoy and are educated by the content on our website. We will respond to all inquiries promptly and with the care which ODC has become known for.

Injection moldingtoolingcost

ODC also produces highly engineered solid machined dies, manufactured from high grade tool steels with precise in-house heat treatment processes resulting in unsurpassed quality and functionality for producing critical parts.

We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

Today, ODC has grown to include world class custom Thermoformed Packaging Tooling, Automotive Tooling and Stand Along Machines.

Injection tool name

We take tremendous pride in being one of the leading suppliers of contour, bypass and sharktooth style trim tools in North America. We are experts at combining these styles and secondary functions such as assembly into our tools, to accommodate multiple applications and reduce part processing times. Known industry wide for our precise, maintenance friendly and long-lasting tools for soft trim, further substantiates our reputation as a leading tool shop. Our product offering also includes vacuum, compression and twin-sheet molds with the ability to supply waterjet fixtures, check fixtures and gauges through partner companies.

A drill bit is a cutting tool bit that’s designed to create holes in objects. You can install a drill bit on a power drill, after which you can use it to drill holes. As you press the spinning drill bit against an object, the flutes will scoop out and remove material from the object. The end result is a uniform hole in place of where you guided the flute.

Injectionmould tooling

Drill bits and router bits are designed for different types of power tools. Drill bits, of course, require the use of a power drill. Router bits, in comparison, require the use of a router. Not to be confused with the networking equipment of the same name, routers are handheld power tools that feature a flat base and a spinning bit. They are commonly used in carpentry and woodworking applications.

Injection moulding process step by step

One of the main differences between drill bits and router bits is that the former is used to create holes in objects, whereas the latter is used to cut and shape objects. If you simply want to create a pilot hole for a screw, you should use a drill bit. If you want to create a joint or decorative cut, on the other hand, you should use a router bit.

We enjoy long term mutually beneficial working relationships with some of the best companies in thermoformed packaging, automotive parts and the material converting industry.

Stand Alone Machines can provide a more flexible and cost-effective alternative to traditional processing methods. Whether the operation is trim, fastening, inspection/verification, sonic welding, lamination or other secondary processes, we have the experience, reputation and drive to exceed your expectations.

Founded in Waterloo, Canada in 1923, ODC Tooling & Molds (Ontario Die Company) was dedicated to the manufacture of the finest cutting dies available for the growing rubber, leather and footwear industries.

With 90 plus years of experience, ODC has mastered combining both the science and the art of producing the world’s best forged dies. Traditional industrial blacksmithing techniques are used in conjunction with modern grinding, CNC machining and wire EDM processes to achieve industry leading reliability and accuracy.

0086-813-8127573

0086-813-8127573