Mill-Right Woodworking - Custom and Specialty Woodworking ... - woodworking mill

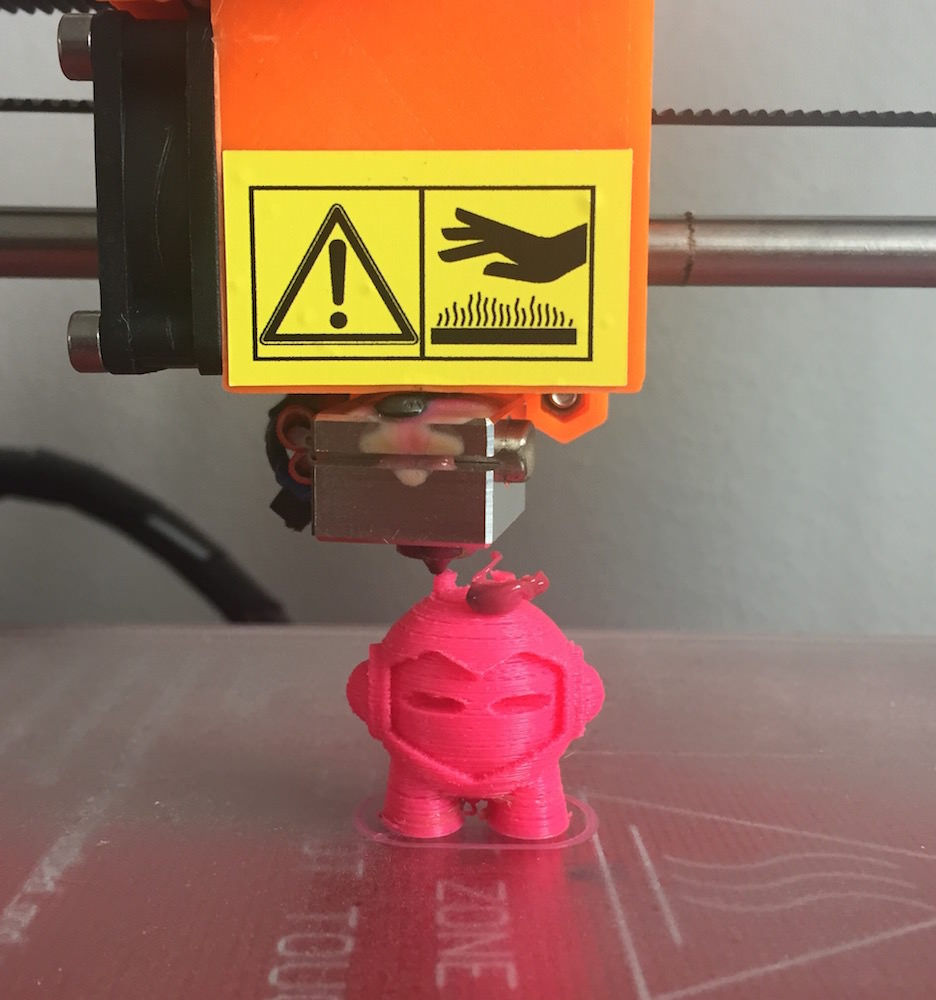

Yes, but feel free to set the parameter width to .5mm if you want those walls 1mm and don't want the additional passes. Assuming Slic3r PE and .4mm nozzle: if the parameter is set to .45, a 1mm width will require 3 passes. You can of course change the parameter to up to twice the width of the nozzle diameter…. So you could set your width up to .8mm with a .4mm nozzle (I always do this when I set “Spiral Vase” mode on). After a year of printing (2000+ hrs.) on my MK2 (w/S upgrade), I’ve settled on 1.2mm using Slic3r PE for a general minimum on exterior walls. I do use thinner walls in some cases, but I do like to keep multiples of .4mm. I would suggest you slice your model, then examine your “Platter > Layers” tab to see how many passes a wall requires. I think anything under 1mm gets a little iffy, but the MK2 at least does an excellent job even then. I am looking forward t seeing how my soon to be received MK3 compares to my MK2 in this regard. Attached picture shows a 3 pass 1.2mm wall using a MakerGeeks Maker PLA.

With my 1mm walls in mind, what would happen if I changed this setting in Slic3r to .5mm instead of .45? Is that ill advised because .45 is optimal for the .4mm nozzle diameter?

Tri-V Tool & Mfg Co. is a manufacturing company specializing in fixtures, automation, components machines, cable assembly, machining, and design services. Established in 1984 by the Vyhlidal brothers, the company has grown to offer a wide range of machining capabilities including CNC machining, molds, fixtures, waterjet cutting, Swiss machining, and more. With expertise in manufacturing from concept to prototypes and mass production, Tri-V Tool provides comprehensive services in design, tooling, automation, and production of components and assemblies. The company values hard work, fair pricing, excellent quality, and attention to detail, maintaining a clean shop environment. Tri-V Tool & Mfg Co. focuses on building strong partnerships with customers and vendors, offering innovative solutions to manufacturing challenges.

Please excuse my ignorance on this, as I'm relatively new to 3D printing. I am printing architectural/structural models, many of which have long, thin vertical walls. I'm wondering if the MK3 and its .4mm nozzle have an optimal wall thickness that should, at least in theory, yield higher quality output, reduced print time, reduced thrashing of the X axis, etc.

Definition of carbide insert. Shaped piece of a hard metal compound, sometimes inset with diamonds, formed by the pressure molding and sintering of a mixture of ...

A good thin wall thickness is a multiple of extrusion width defined in the slicer (Slic3rPE is 0.45mm). 0.45mm, 0.90mm ... I use this when making models optimized for a specific printing.

Tri v toolmfg

Create or log in to My Show Planner to see Onsite Photos. Contact Information. 7680 Innovation Way. Mason OH 45040. United States of America.

I'm currently making all my vertical walls 1mm thick, and I'm really impressed how well the MK3 handles these. They do come out relatively straight, smooth and rigid. Just curious if there is a theoretical sweet spot that I should be using instead. Multiples of .4 for example? .4 => .8 => 1.2 ?

Ah, thanks. So with .45mm set as the extrusion width, does that mean a wall thickness of 1mm (rather than .9mm) is causing unnecessary extruder movements perpendicular to the length of the wall? Movements that could either reduce linear print consistency, or slow down the print?

You are currently viewing all of our tools! Alphabetical Listing of Tools. $10,000 Pyramid. View Tool. 100 Squares Reward System. View Tool.

Tri-V Tool & Mfg Co. is a manufacturing company specializing in fixtures, automation, components machines, cable assembly, machining, and design services. Established in 1984 by the Vyhlidal brothers, the company has grown to offer a wide range of machining capabilities including CNC machining, molds, fixtures, waterjet cutting, Swiss machining, and more. With expertise in manufacturing from concept to prototypes and mass production, Tri-V Tool provides comprehensive services in design, tooling, automation, and production of components and assemblies. The company values hard work, fair pricing, excellent quality, and attention to detail, maintaining a clean shop environment. Tri-V Tool & Mfg Co. focuses on building strong partnerships with customers and vendors, offering innovative solutions to manufacturing challenges.

Carbide end mill bits are solid round milling cutters used for applications such as slotting, profiling, face milling and plunging.

View Mhc Dooley's email address (ste*******@tippedoff.com) and phone number profile as Co-Founder at Tipped Off, located in Pittsburgh.

I would suggest turning off "ensure vertical shell thickness" in Print settings (always, not just for this). That is the worst feature in slic3r and has ruined more prints than I care to count. I should start a petition.

Tri v toolcnc

You can change the widths in the Advanced Print settings in Slic3r PE. I have done some small tests, and found that .7mm single walls come out very nice. Just did a test print on a small wall that was .7mm thick, with all the widths set to .7mm in Slic3r. came out beautiful, albeit they measured 1.1mm with calipers.

Aug 2, 2024 — Heavy duty 4x8 ATC CNC router with tapping head is professional for drilling screw holes on aluminum, brass, copper and other soft metals.

... & Chargers · Hedge Trimmers · Brush Cutters · Chainsaws · Tying Machine. Industries. Industries Back. Green Industries. Green Industries Back. Viticulture ...

Nov 14, 2008 — The formula should be: RPM=(SFMx12)/(pi x dia.) to calulate take 80 x 12. divide the result by pi divide the result by the diameter.

... TURNING INSERTS. aHow this section page is organized z Organized ... chart below. Multiply the coefficient value by the recommended cutting speed ...

Sep 23, 2014 — Tungsten's melting point of 3422 °C is the highest of all metals and second only to carbon's, for which melting occurs only at high pressure ...

0086-813-8127573

0086-813-8127573