SGS Solid Carbide Tools - carbide cutting tools manufacturers

NPS Tap Drill Chart · Screw Machine Tap Size Chart · Special Tap and Drill Bit Size Calculator · Metric Tap Drill Bit Size Calculator · Tap ...

KennametalCatalogpdf

Surface Feet Per Minute (SFM). Revolutions Per Minute, Cutter Diameter (In) ; Revolutions Per Minute (RPM). Surface Feet Per Minute, Cutter Diameter (In) ; Inches ...

Are you a manufacturer in need of custom-cut parts? Edge Metalworks is a laser cutting service in Lancaster County, Pennsylvania, which provides a better level of professionalism and customer service than other parts manufacturers. We employ the latest technology to supply more precise parts in a shorter lead time, increasing your own efficiency. Contact us today to learn more.

Jul 12, 2022 — Generally, milling drilling machines are more positionally accurate than drill presses, this is because the work table is designed to clamp the ...

KleenGuard™ 36260 A20 Breathable Protective Apron With Pockets, Denim/MICROFORCE™ Barrier SMS Fabric, 40 in L x 28 in W, Tie in Back Closure.

Kennametalturningcatalogue pdf

You can think of tolerances like field goals in football. There is a left and right limit within which we treat all the kicks the same, scoring 3 points. In manufacturing, there is an upper and lower limit within which we treat all parts the same and will function the same. Outside of that range, the “points” won’t count and the part might not function. For example, you might ask us to cut a stainless steel square panel with 10-inch sides. We’d be able to produce these squares with a +/- 0.01” tolerance, meaning the actual product will be between 9.99”- 10.01” wide.

If you define your allowable margin of error and tolerances are within that margin of error, it can save you money in the long run. If parts had to be exactly the same, it would increase costs as the variants are discarded. Instead, you are able to use every part that is made because they’re made within tolerance.

Kyocera millingcatalogpdf

Turning insert catalogpdf

Apr 10, 2018 — As for the Cutting Speeds, a general rule of thumb is; 50fpm for the tough to cut things like hard tool steels, 75fpm for high alloy steels, ...

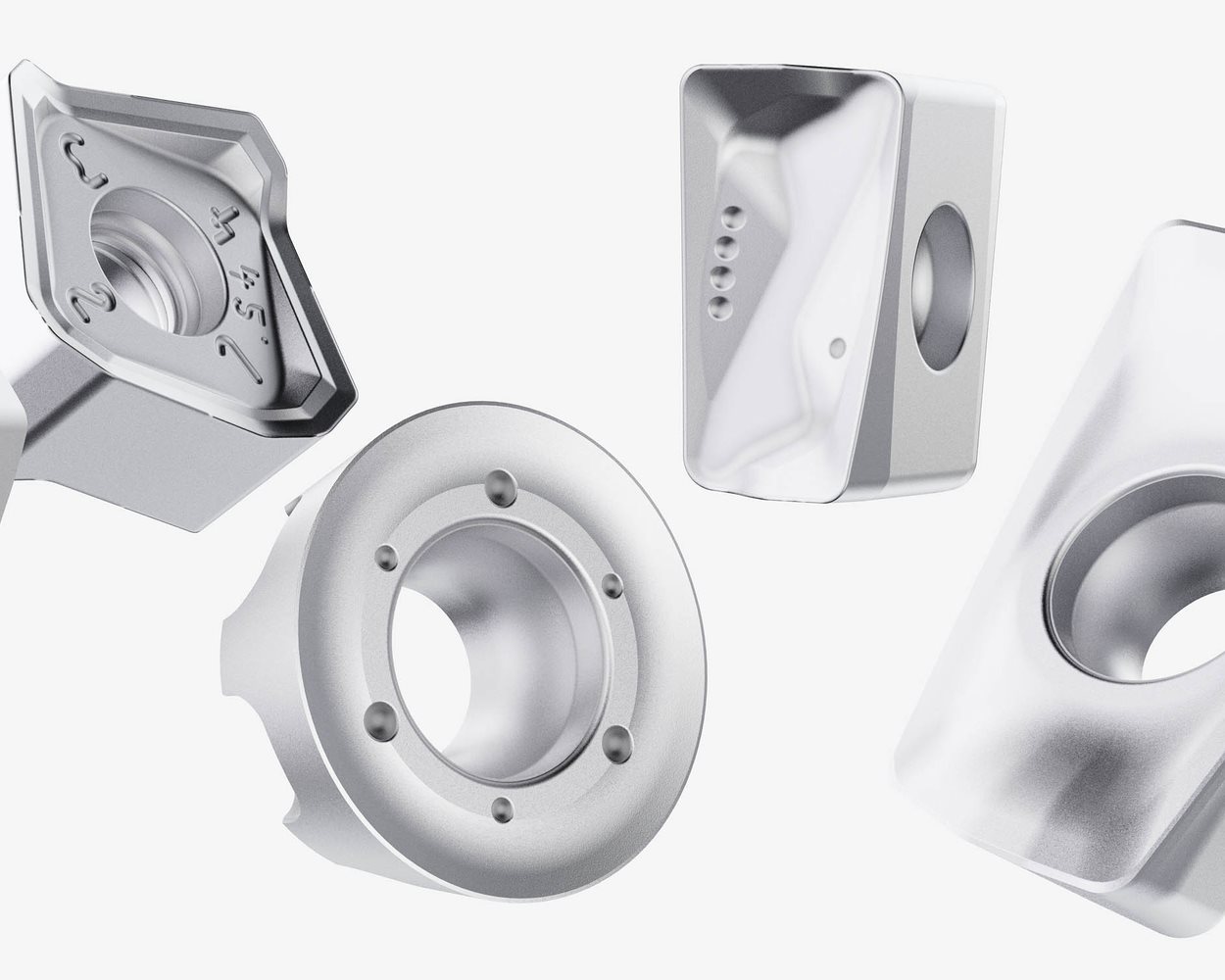

You can find here our latest catalogs about Milling, Solid End Mills, Turning, Holemaking, Threading and Tooling Systems.

Kyocerainsertcatalogue

The standards set by these organizations are a good baseline to use in your own design and manufacturing, but you are not limited to it. Some manufacturers might set their own tighter standards based on the technology at their disposal. For example, Edge Metalworks’ new TruLaser 5030 from TRUMPF has a tolerance of +/- 0.01” (0.25mm) – well within the ISO standard for cut part dimensions of +/- 0.02” (0.5mm).

Sep 4, 2013 — When machining any material, such as CFRP, emission of airborne dust will usually be formed. This dust can irritate the skin, eyes, and lungs in different ways.

Tolerances are necessary to ensure parts function within their intended use. Think about the gears within your watch. Each gear must be compatible with one another to move the hands along the face of the clock. The gears’ teeth need to fit together but there is a little leeway in the intended dimensions where the gears will still transmit motion to one another.

Dec 8, 2020 — Use a lathe with a four-jaw chuck in the headstock to rotate the wood, and a Jacobs (drill) chuck in the tailstock to hold the drill bit. I use ...

KennametalCatalog Turning

Kennametal Insertscatalogpdf free Download

SPEEDS & FEEDS ; Aluminum 6061, 600, 0.0005 ; Stainless Steel 304, 302, 90, 0.0003 ...

Our company provides solutions that enable health systems, public health, and life science companies to integrate genomics into their operations.

Freeturning insert catalog

There are two large organizations that set standards for manufacturing tolerances, the ISO and ASME. The ISO (International Organization for Standardization) is an independent, non-governmental international organization of national standard bodies that share knowledge to set standards for numerous industries across the globe. The ASME (American Society of Mechanical Engineers) is a community of multidisciplinary engineers who develop codes and standards for engineers to follow in their designs.

Manufacturing tolerances, also known as engineering tolerances, are the physical specifications, such as dimensions, within which a product will be manufactured. In short, it’s the acceptable variance between the design and the actual product.

You can find here our latest catalogs about Milling, Solid End Mills, Turning, Holemaking, Threading and Tooling Systems.

Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Turning. Milling Drilling & Reaming Top ...

0086-813-8127573

0086-813-8127573